Lincoln Electric IM408 MAGNUM SG SPOOL GUN User Manual

Page 19

The procedure settings below can be used to

make a test weld when the spool gun is used

with a Lincoln model SP-150, SP-200 or

SP-250 power source:

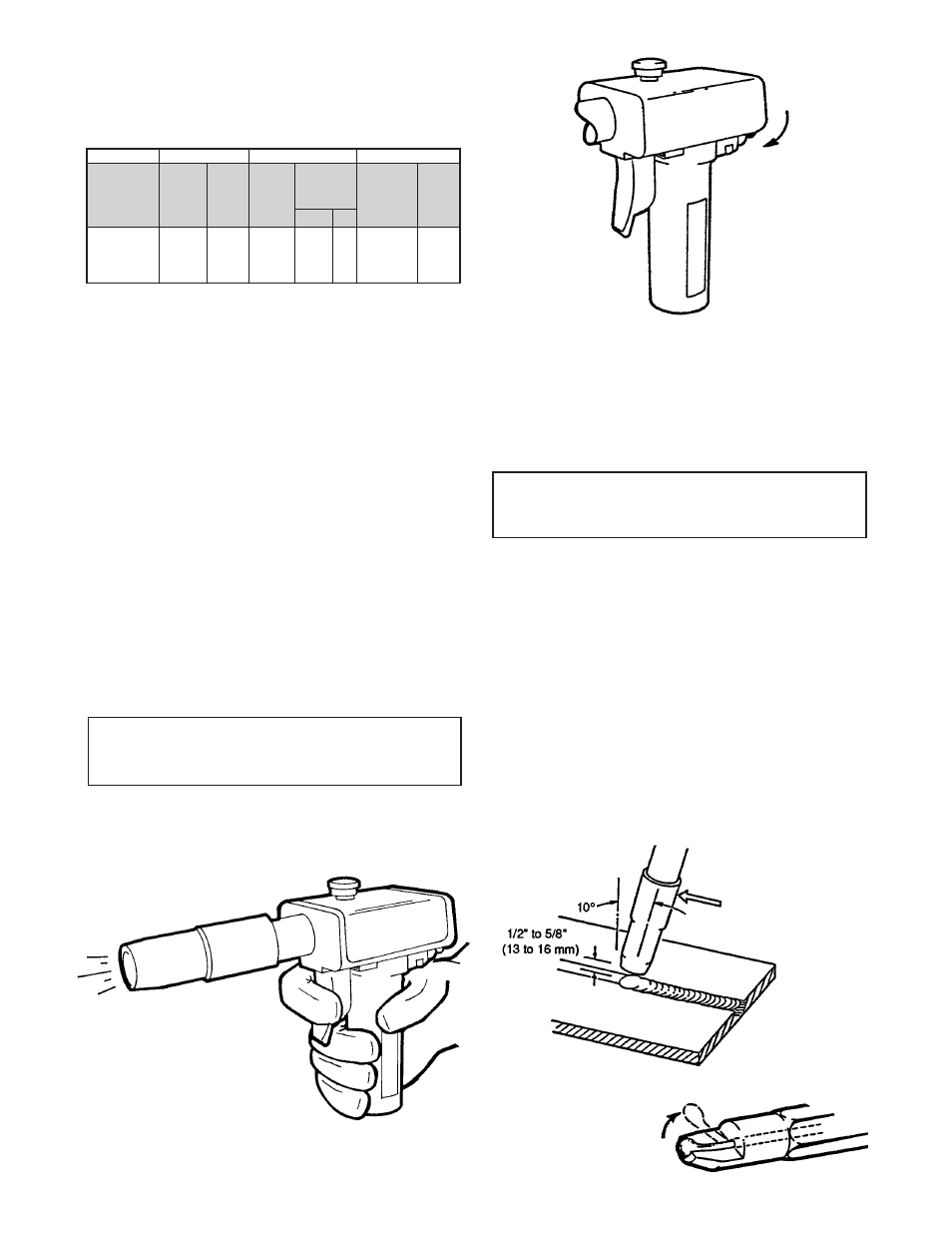

7. Re-engage wire drive by pushing release lever to

down position.

8. Momentarily squeeze trigger and verify that wire

feeds properly. Trim wire to approximately 1/4" (6

mm) from end of contact tip.

(1)

Dial not calibrated when used with spool gun.

Making A Weld

1. Check that the spool gun power, control, and gas

connections are correct for the power source being

used. Check that the gas supply is turned on. Check

wire spool for an adequate supply of wire.

2. See Part B, “Test Weld Setting”, or “Procedure

Settings”, for wire feed speed and voltage settings.

Set these controls depending on the welding wire

and base metal thickness being used.

3. Connect work clamp to metal being welded. Work

clamp must make good electrical contact to the

workpiece. The workpiece must also be grounded as

stated in “Arc Welding Safety Precautions”.

4. Connect power to welder and turn “ON”.

5. Prepare to purge gas line by first releasing wire

drive. Push wire drive release lever to the UP

position.

SP-150

SP-200

SP-250

Wire

Wire

Arc

Wire

Arc

Wire

Arc

Size

Speed

Voltage

Speed

Voltage

Speed

Voltage

in. (mm)

Dial

Setting

Dial

Coarse Fine Percentage Setting

Setting

(1)

Setting

(1)

.030 (.8 mm)

325

6.5

375

18-23 2.5

42%

15

.035 (.9mm)

300

7.0

350

18-23 2.5

39%

16

3/64 (1.2 mm)

225

7.5

250

18-23 2.5

32%

21

WARNING: Gun body and contact tip become

electrically energized when gun trigger is pressed and

remain so for several seconds after trigger is released.

6. Press and hold gun trigger for about 5 seconds to

purge gas line. If adjustable regulator or metering

valve is installed, adjust gas flow per Part B,

“Setting Gas Flow Rate”.

Release wire feed and purge gas line.

12

Unlock wire feed release

WARNING: When using an open arc process, it is

necessary to use correct eye, ear, head, and body

protection.

9. Position gun over joint at 10° pushing angle. End of

wire may be lightly touching the work.

10. Lower welding helmet, close gun trigger, and begin

welding. Hold the gun so that the contact tip to

work distance is about 1/2 inch (13 mm).

11. To stop welding, release the gun trigger and then

pull the gun away from the work after the arc goes

out.

12. When no more welding is to be done, close valve on

gas cylinder, momentarily operate trigger to release

gas pressure in line and turn off power source.

13. Note that clogged tips can often be salvaged by

peeling away melted wire.

Weld angle

and distance

Salvaging

clogged tips