Installation, Figure 2 – Lincoln Electric IM439 MAGNUM COOLERS 20-I User Manual

Page 12

A-5

INSTALLATION

MAGNUM COOLER 10 & 20

A-5

hand side of the connector block Again, tightly secure

the connector nut of the hose into the connector block

of the Cooler with an adjustable or 11/16” open-ended

wrench to insure that no leaking occurs. BE CER-

TAIN THAT NO LEAKS EXIST WHEN COOLER IS

TURNED ON. A LEAK WILL DEPLETE RESERVOIR

VOLUME, CAUSE POOR COOLING PERFOR-

MANCE AND REDUCE GUN OR TORCH LIFE.

If the connector nut on a water hose does not mate

with connector block at the back of a Magnum Cooler:

Order:

(2) T15007-2 Connector Nuts*

(2) T15008 Nipples*

(2) S10888-35 Hose Clamps*

For proper installation, remove the connector nut from

the water hose by making a straight cut 1/4-1/2” (6-

12mm) away from the nipple located inside of the

hose. Take the nipple and the connector nut, and

insert the nipple into the connector nut so that the

threaded end of the connector nut points away from

the barbed end of the nipple. Place the hose clamp

over the water hose and twist the barbed end of the

nipple into the hose until the shoulder of the nipple is

flush with the end of the hose. Secure the hose onto

the nipple by tightening the hose clamp around the

nipple. No water can leak from the connection if it is

properly attached. Repeat the process for the other

water hose.

NOTE: Be certain that only 5/8-18 left hand male

nuts with clean and smooth threads are used on

your water hoses. Poor connections cause

water to leak at connector block, down hose

lines, and eventually out the case sides of the

unit.

* The connector and nipples listed fit tightly onto 5/32”

(4.0mm) to 3/16” (4.8mm) inner diameter hose, but, if

clamped tightly to the hose can fit up to .250” (6.4mm)

inner diameter hose.

HORIZONTALLY MOUNTING MAGNUM COOLERS

ON LINCOLN TIG POWER SOURCES

Magnum Coolers can be mounted either upright or

horizontally. For a complete compact system,

Magnum 10 or 20 Cooler can be mounted horizontally

on the roof of Lincoln TIG Power Sources using the

optional K559-2 Horizontal TIG Mounting Bracket. For

proper installation, follow the instructions provided

with the kit. (See Figures 3a and 3b)

VERTICALLY MOUNTING MAGNUM COOLERS TO

LINCOLN UNDERCARRIAGES K874, K840-1*, K841-

1*, or K842-1*

When placing the Cooler 10 or 20 at the back of a

Lincoln Undercarriage used in tandem with a Lincoln

MIG power source, order K559-3 Magnum Cooler

MIG Mounting Bracket.

Reference Figure 3c and Table 2 for proper connec-

tion of the bracket to the back bolt pattern of the

Cooler. With the four Phillips head screws supplied,

align the bracket onto the back of the Cooler at the

proper holes displayed in Figure 3c. Do not fully tight-

en the bracket allowing the bracket to slightly move up

and down. Place the Cooler at the back right of the

undercarriage so that the lip of the Cooler bracket

rests on the top of the undercarriage upper cylinder

support. Align the holes of the Cooler bracket with the

holes on the undercarriage upper cylinder support.

Fasten the Cooler bracket with the holes on the

undercarriage upper cylinder support. Fasten the

Cooler bracket onto the undercarriage support with

both 1/4-20 bolts, 1/4-20 hex nuts, plain washers and

lock washers provided. Be certain to tighten all the

fasteners when the installation is complete.

* Not available at time of printing.

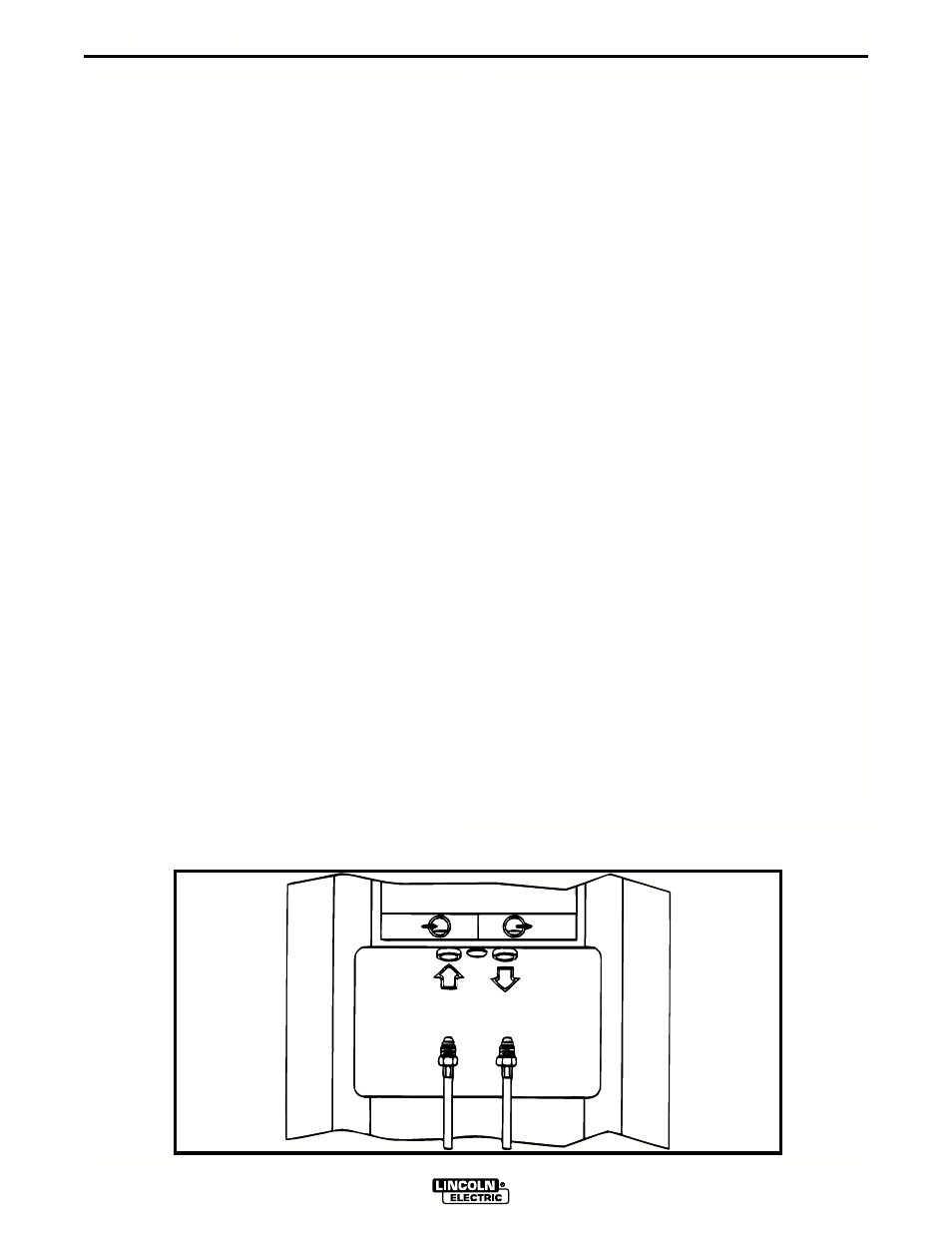

FIGURE 2

Inlet and Outlet Hose Connection Diagram

COOLANT

IN

COOLANT

OUT

FROM

HEAT

SOURCE

(RED)

TO

HEAT

SOURCE

(BLUE)