Installation – Lincoln Electric IM615 K1614-2,-3 MAGNUM 250 NR GUN & CABLE User Manual

Page 11

B-2

INSTALLATION

MAGNUM® 250 NR

B-2

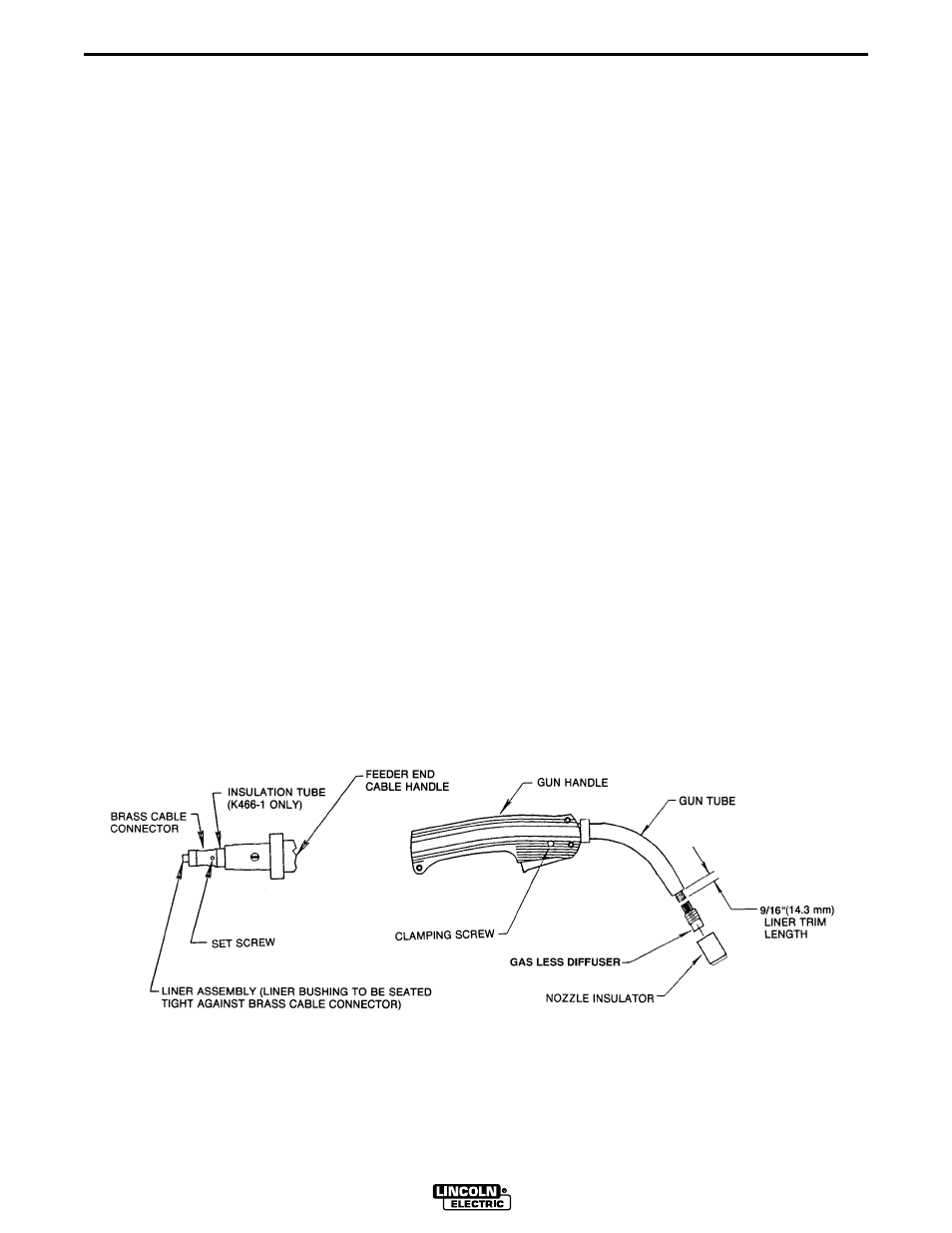

K466-5 INSTALLATION (For L-Tec feeders equipped

with an L-Tec feeder connector assembly, MIG 35, MIG

31A, 225...)

a. Remove brass cable connector (see Figure 1) from

the K466-5 kit and screw it onto the feeder end of

the gun cable. Tighten the connection with the

wrench provided.

b. For L-Tec machines that require trigger lead con-

nections to be made at a terminal strip located with-

in the machine (L-Tec 225), a gun control cable with

forked terminals is provided. Connect the terminat-

ed leads to the terminal strip. For a machine that

requires a twist-lock gun control cable connection,

continue to use the L-Tec gun control cable provid-

ed with the L-Tec wire feeder connector assembly.

Connect the twist-lock plug to the proper receptacle

on the machine

K466-6, K466-7 and K466-9 Installation (Wirematic,

Hobart Series 2000 Feeders and SP100T Type feed-

ers)

a. Remove brass cable connector (see Figure 1) from

the connector kit and screw it onto the feeder end of

the gun cable. Tighten the connection with the

wrench provided.

b. Attach the gun control cable provided to the trigger

connector on the front of the wire feeder.

LINER INSTALLATION

a. Lay the gun and cable straight on a flat surface.

b. Make sure that the set screw in the connector end

is backed out so as not to damage liner or liner

bushing. Remove and save the nozzle insulator, and

gas less diffuser from the end of the gun tube

assembly.

c. Insert a new untrimmed liner into the connector end

of the cable. Be sure the liner bushing is stenciled

appropriately for the wire size being used.

d. Fully seat the liner bushing in the connector and:

For all K466 connector kits except K466-3 and

K466-4, tighten the set screw in the cable connec-

tor.

or

For K466-3 and K466-4, screw in the connector cap

provided in the kit until it seats on the face of the

bushing. Then insert the appropriate piece of liner

material into the connector cap and tighten the set

screw. Three pieces of liner material are included in

these connector kits to help guide the electrode

through the connector cap. The piece with the

smallest inner diameter is designed for .045” (1.2

mm) maximum diameter electrode. The next largest

diameter is for 1/16” (1.6 mm) maximum diameter

electrode. The largest diameter piece of liner mate-

rial is for 5/64” (2.0 mm) maximum diameter elec-

trode.

Figure 1