Operation, General description – Lincoln Electric IM910 LN-15 WIRE FEEDER User Manual

Page 16

B-2

OPERATION

B-2

GENERAL DESCRIPTION

The LN-15 is a light weight, portable, durable semi-

automatic wire feeder.

The LN-15 accommodates spools 8" (200mm) diame-

ter up to 4" (100mm) wide.

The domestic feeders comes factory equipped with a

K1500-2 Magnum Tweco-compatible style #2-#4 gun

bushing. Other K1500 series gun bushings are avail-

able as field installed options. European models are

factory equipped with a Fast-Mate adapter.

The wire drive is capable of operating in either a "CV"

or "CC" mode. A constant voltage (CV) power source

is recommended for flux-cored arc welding (FCAW)

and gas metal arc welding (GMAW) to obtain code

quality results. However, the LN-15 may also be used

with a constant current (CC) power source to obtain

passable results for non-critical quality applications.

The “dual procedure” mode drops the WFS to 83% of

the original set point. The voltage setting remains the

same.

• Burn-back is adjustable from 0.0 to 0.25 seconds,

with a default of 0.00 seconds.

• The preflow time is adjustable from 0.00 to 25.0 sec-

onds, with a default of 0.00 seconds.

• The postflow time is adjustable from 0.0 to 25.0 sec-

onds, with a default setting of 0.0 seconds.

The Control Cable Model features remote voltage

control with a potentiometer on the front of the feeder.

The operation of the voltage control is similar to other

feeders having "remote control" kits, such as the LN-

25. While welding, the voltage may be adjusted as

desired. The voltage setting is not a "preset" value.

Electrode output is energized in response to the gun

trigger by signals sent to the power source via the

control cable.

LN-15 CONTROL CABLE MODEL (CE)

DUTY CYCLE

The LN-15 wire feeders are intended for semi-auto-

matic use. The maximum rating of the LN-15 is based

upon a 60% duty cycle; 6 minutes of welding followed

by 4 minutes of idling within a 10 minute period.

RECOMMENDED PROCESSES

The LN-15 wire drive feeds electrode for various

processes as defined below in Table B.1.

The Control Cable Model is suitable for GMAW,

GMAW-Pulse, GMAW-STT and FCAW semi-auto-

matic applications within the rated duty cycle.

PROCESS LIMITATIONS

• The control cable model is not recommended for

SAW, SMAW, GTAW or CAG.

• The control cable model works only with power

sources having remote control output.

EQUIPMENT LIMITATIONS

Codes 11033 and higher

• The LN-15 cannot be used with the K1500-4 gun

adapter bushing.

OPERATIONAL FEATURES AND

CONTROLS

• Remote voltage control at the LN-15.

• Built in flow meter for adjusting shielding gas.

• Cold Feed/Gas Purge switch.

• 2 step / Trigger Interlock switch (codes 11033 and

above only)

• Digital wire feed speed control.

• Digital display of welding voltage.

• Adjustable preflow and postflow times

• Adjustable burnback times.

• ON / OFF switch (codes 11033 and above only)

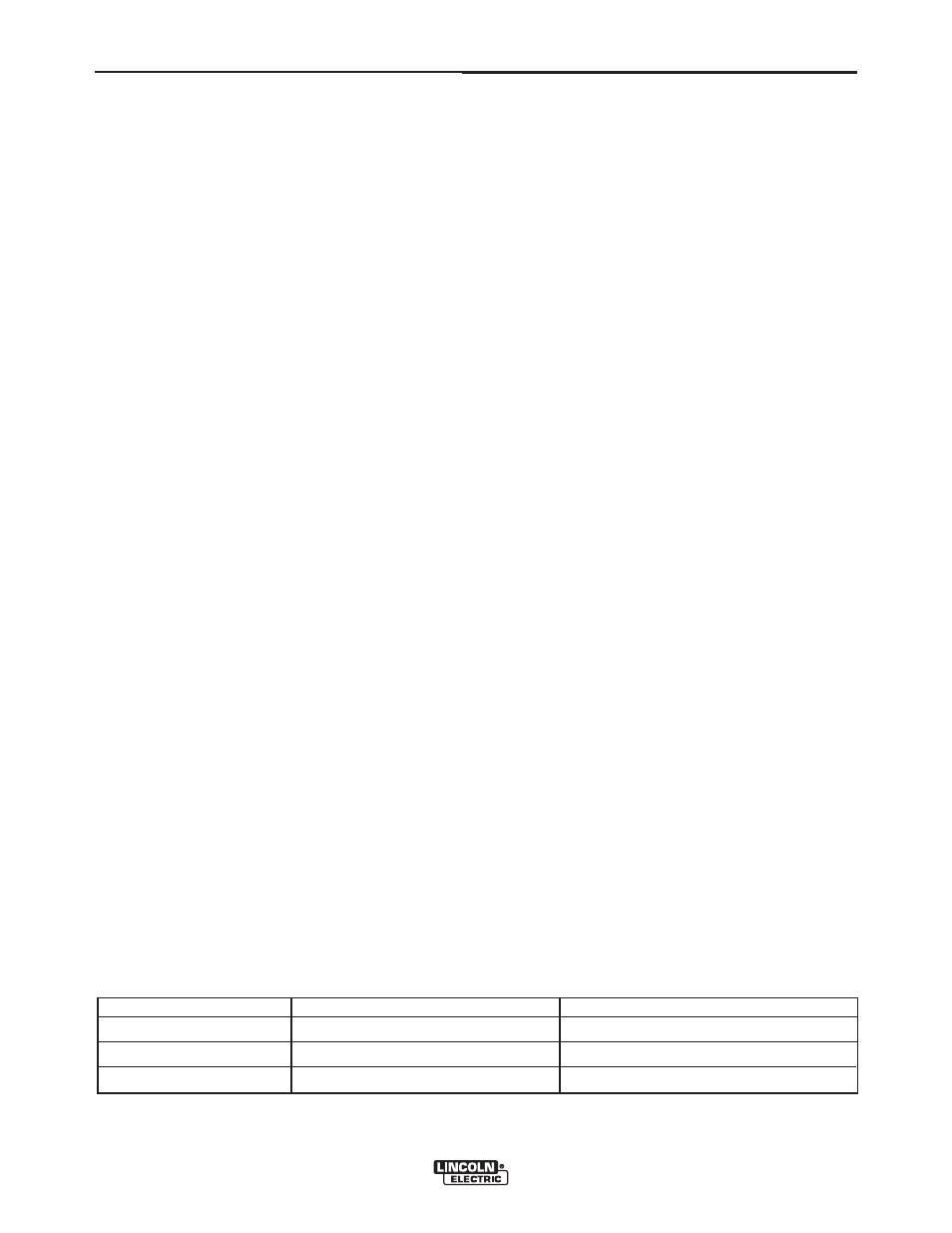

Process

Wire Diameter Range

Wire Feed Speed Range

GMAW

0.023 - 0.052" (0.6 - 1.3 mm)

50 - 700 ipm (1.3 - 17.8 m/minute)

FCAW

0.045 - 0.052" (1.2 - 1.3 mm)

50 - 700 ipm (1.3 - 17.8 m/minute)

FCAW

1/16 - 5/64" (1.6 - 2.0 mm)

50 - 400 ipm (1.3 - 10.2 m/minute)

TABLE B.1