Troubleshooting, Caution – Lincoln Electric IM734 LN-15 WIRE FEEDER User Manual

Page 25

E-3

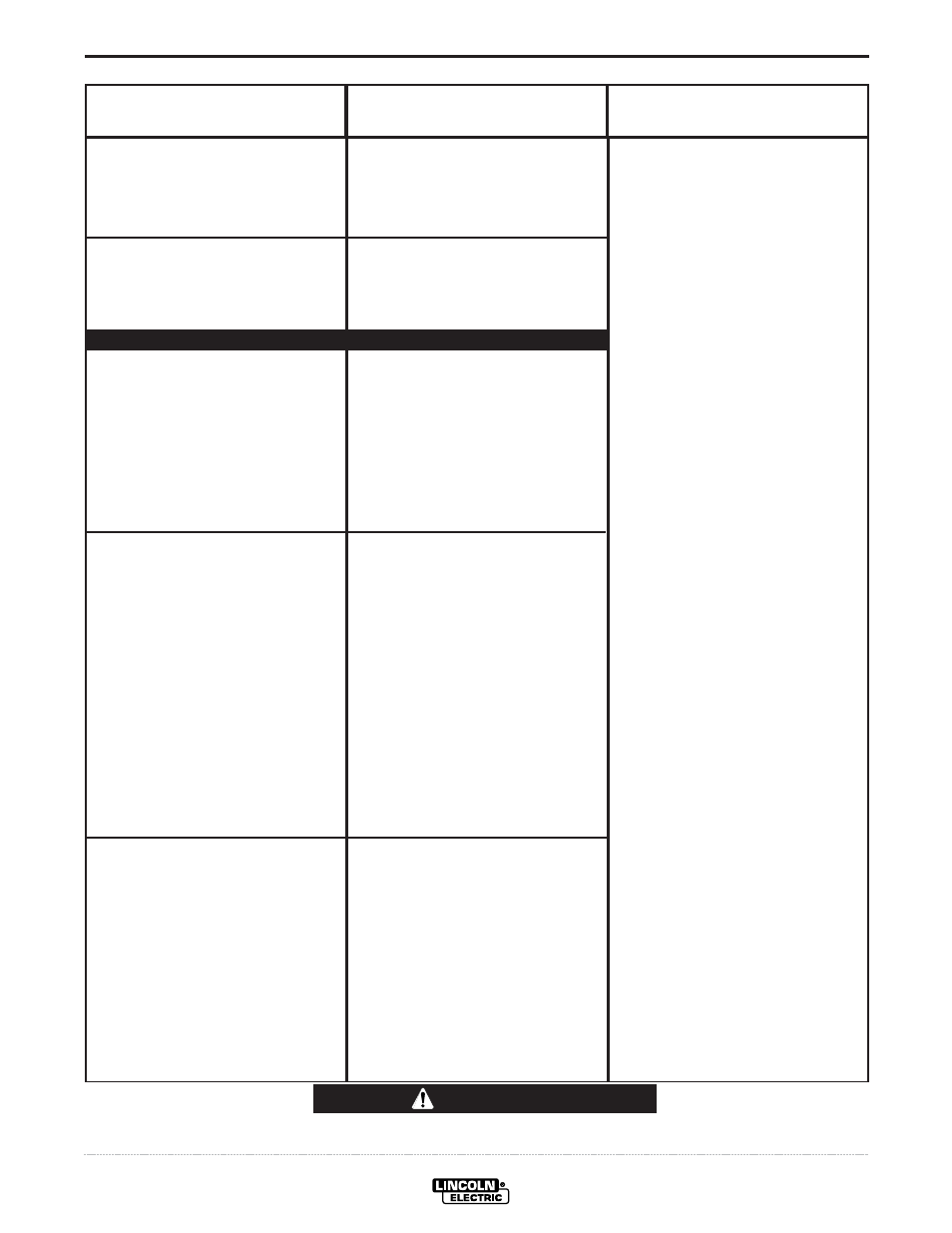

TROUBLESHOOTING

E-3

LN-15 CONTROL CABLE MODEL

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility

for technical troubleshooting assistance before you proceed.

CAUTION

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

No output, no display.

The actual wire feed speed does not

match the setting on the display.

The arc burns back to the tip.

Porosity in the weld.

1. The power source is not turned

on.

2. The control cable is not connected

or damaged.

1. The LN-15 is set for constant cur-

rent

“

CC

”

welding instead of con-

stant voltage

“

CV

”

welding.

1. The spool of electrode is tangled.

2. The electrode and work leads are

reversed (welding with the wrong

polarity.)

3. The liner is clogged.

4. The contact tip is worn.

5. The wire drive tension is improp-

erly set.

1. The part being welded is wet, dirty

or rusty.

2. The electrode being used is wet,

dirty or rusty.

3. There is insufficient shielding gas

flow from possible cuts in the gas

hose

4. There is moisture or water in the

shielding gas line.

5. There is too much shielding gas

6. There is too much wind or drafts.

7. The arc voltage is set too high.

8. The wrong shielding gas is being

used.

If all recommended possible areas of

misadjustment have been checked

and the problem persists,

Contact

your local Lincoln Authorized

Field Service Facility.

WELDING ISSUES