Operation, General description – Lincoln Electric IM734 LN-15 WIRE FEEDER User Manual

Page 13

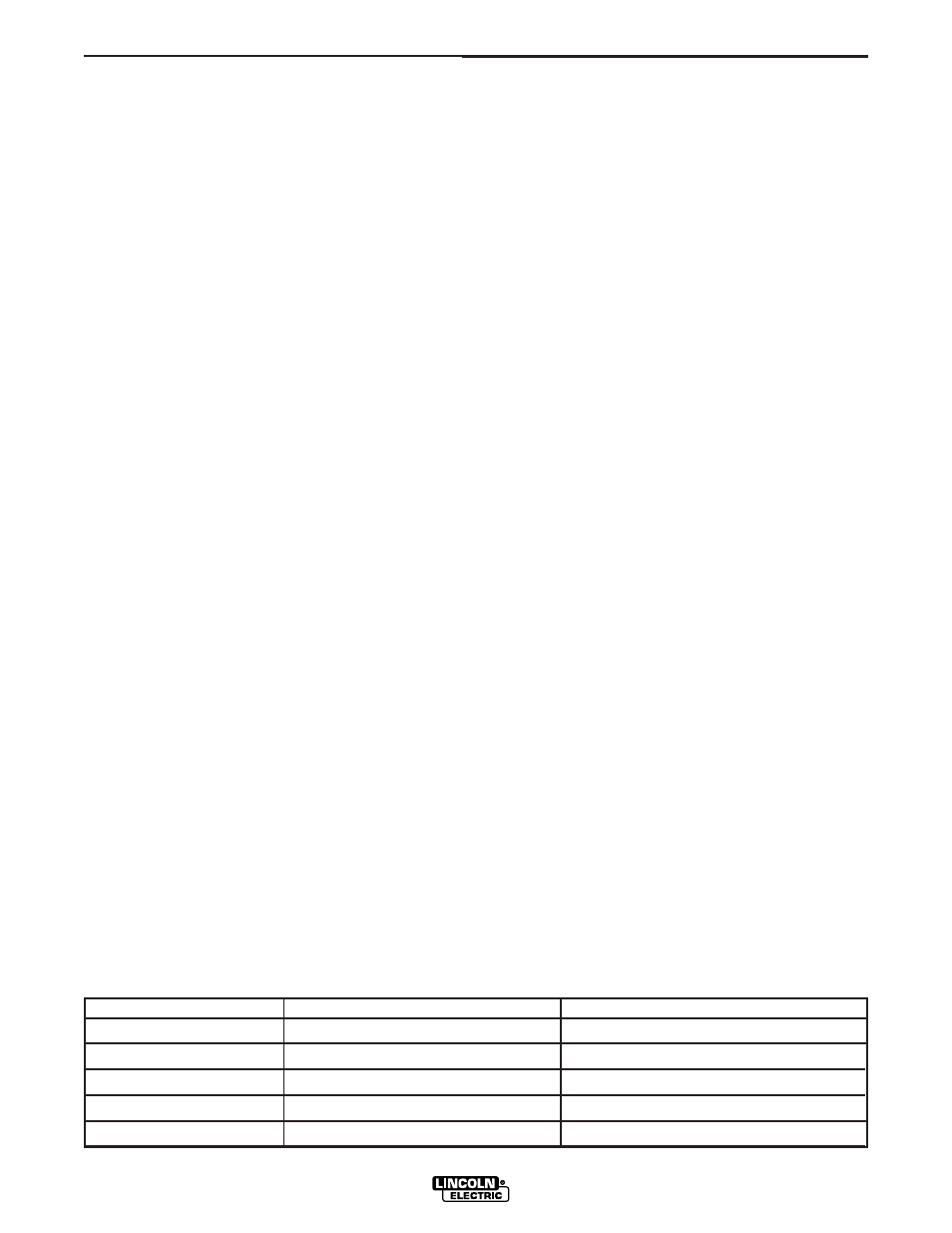

Process

Wire Diameter Range

Wire Feed Speed Range

GMAW

0.023 - 0.052" (0.6 - 1.3 mm)

50 - 700 ipm (1.3 - 17.8 m/minute)

FCAW- Gas Shielded

0.035 - 0.052" (1.2 - 1.3 mm)

50 - 700 ipm (1.3 - 17.8 m/minute)

FCAW- Gas Shielded

1/16 - 5/64" (1.6 - 2.0 mm)

50 - 400 ipm (1.3 - 10.2 m/minute)

FCAW- Self Shielded

0.035 - 0.052" (1.2 - 1.3 mm)

50 - 700 ipm (1.3 - 17.8 m/minute)

FCAW- Self Shielded

1/16 - 5/64" (1.6 - 2.0 mm)

50 - 400 ipm (1.3 - 10.2 m/minute)

TABLE B.1

B-2

OPERATION

B-2

GENERAL DESCRIPTION

The LN-15 is a light weight, portable, durable semi-

automatic wire feeder.

The Control Cable Model features voltage control with

a potentiometer on the front of the feeder. The opera-

tion of the voltage control is similar to other feeders

having "remote control" kits, such as the LN-25.

While welding, the voltage may be adjusted as

desired. The voltage setting is not a "preset" value.

The LN-15 accommodates spools 8" (200mm) diame-

ter up to 4" (100mm) wide.

The feeder comes factory equipped with a Tweco

style #2-#4 gun bushing. Other K1500 series gun

bushings are available as field installed options.

The dual procedure mode drops the WFS to 83% of

the original set point. The voltage setting remains the

same.

• Burn-back is adjustable from 0.0 to 0.25 seconds,

with a default of 0.0 seconds.

• The preflow time is adjustable from 0.00 to 2.50 sec-

onds, with a default of 0.0 seconds.

• The postflow time is adjustable from 0.0 to 10.0 sec-

onds, with a default setting of 0.0 seconds.

DUTY CYCLE

The LN-15 wire feeders are intended for semi-auto-

matic use. The maximum rating of the LN-15 is based

upon a 60% duty cycle; 6 minutes of welding followed

by 4 minutes of idling within a 10 minute period.

RECOMMENDED PROCESSES

The LN-15 wire drive feeds electrode for various

processes as defined below in Table B.1.

PROCESS LIMITATIONS

• The control cable model is not recommended for

SAW, SMAW, GTAW or CAG.

• The control cable model works only with power

sources that have remote output control capability.

• The LN-15 does not support 4 step trigger operation.

LN-15 CONTROL CABLE MODEL

RECOMMENDED EQUIPMENT

Common MIG Package:

• Magnum 300 GMAW

• LN-15 Control Cable Model

• Control Cable

• V350-PRO

• 0.035 (0.9mm) Drive Roll Kit

• Inert Gas Regulator and Hose

• Weld Cables

Guns:

• 450A FCAW-SS

• 350A FCAW-SS

• Magnum 300 GMAW

• Magnum 400 GMAW

• Magnum 400 DS

• Magnum 400 DP

Welding Power Sources, Engine Drives:

• SAE-400 with CV adapter

• Ranger 9

• Ranger 250

• Ranger 300 DLX

• Ranger 305G

• Commander 300

• Commander 500

Welding Power Sources, Static:

• V350-PRO

• DC-400

• DC-600

• DC-655

• CV250

• CV300

• CV400

• CV655

• Invertec STT II