Operation, Warning – Lincoln Electric IM734 LN-15 WIRE FEEDER User Manual

Page 17

B-6

OPERATION

B-6

LN-15 CONTROL CABLE MODEL

SPRING TENSION ARM

The spring tension arm sets the clamping pressure of

the drive rolls on the electrode. The optimum pressure

varies with the type of wire, wire diameter, surface

conditions, lubrication and hardness. As a general

rule, hard electrodes like solid stainless electrodes

may require greater pressure and softer electrodes

like aluminum may use less pressure.

To set the spring tension arm

• Turn the knob until it is approximately at the #3

mark.

• Press the end of the gun against a solid object that

is electrically isolated from the welder output and

cold feed for several seconds.

• If the wire "birdnests", jams or breaks at the wire

drive than the idle roll pressure is too great. Loosen

the pressure arm by about a 1/2 turn., run new wire

through the gun, and repeat the above steps.

• If the drive rolls slipped on the wire, loosen the

adjustment knob on the feed plate and the gun and

cable assembly forward about 6" (15cm). A slight

waviness will be visible (it will be more visible with

smaller or softer electrodes.) If there are no waves

in the wire, tighten the knob 1/4 turn, reinstall the

gun and cable assembly and repeat the above

steps.

COLD FEED/GAS PURGE SWITCH

Inside the LN-15 is a “center-off” momentary toggle

switch for Cold Feed/Gas Purge.

When held in the UP position, the wire drive will feed

electrode but neither the power source nor the gas

solenoid will be energized. When cold feeding, the

feed speed is the same as the welding wire feed

speed. The wire feed speed may be adjusted by rotat-

ing the WFS knob on the front of the LN-15.

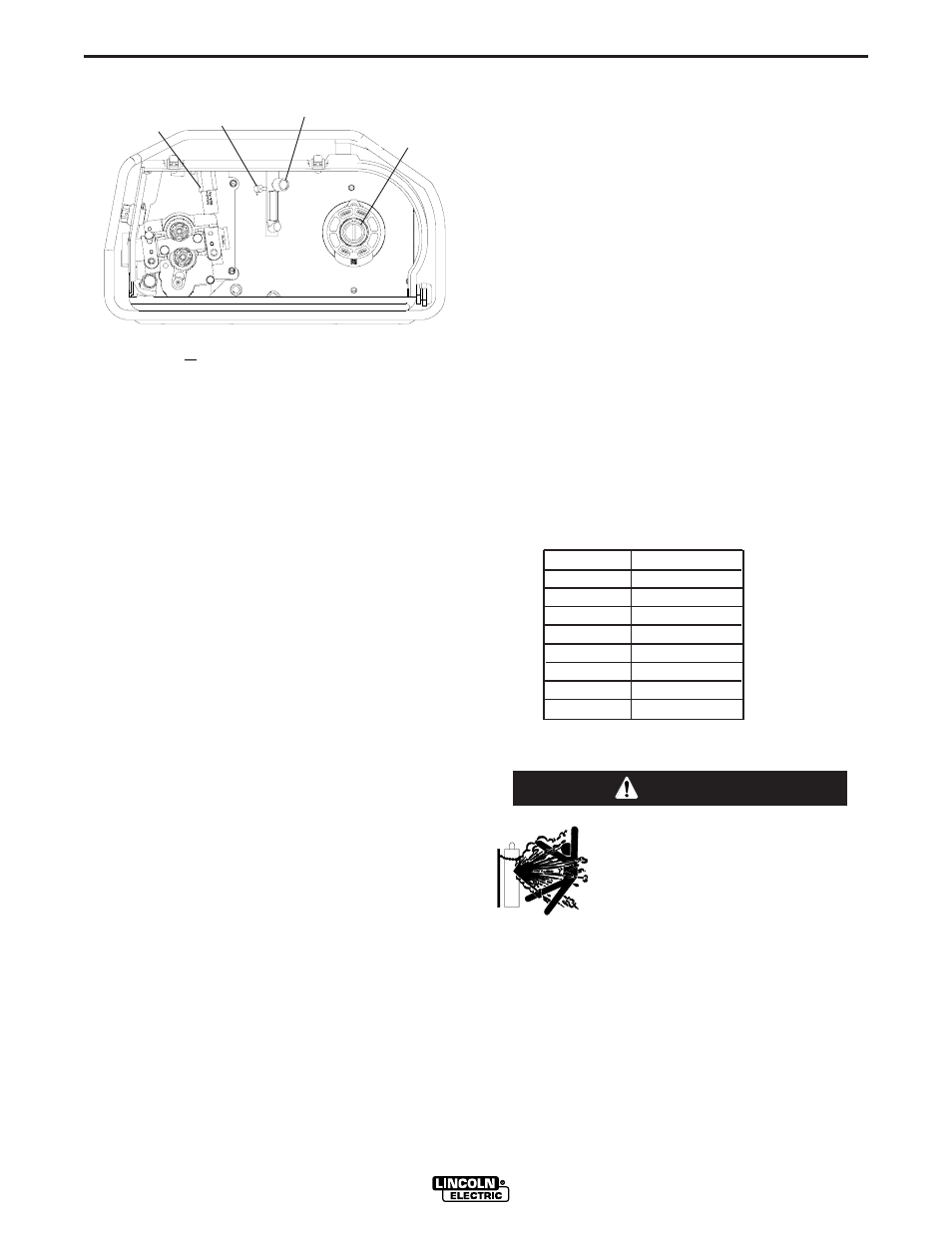

SPRING

TENSION

ARM

COLD FEED/

GAS PURGE

SWITCH

FLOWMETER

SPINDLE

BRAKE

INTERNAL CONTROLS

(Figure B.2)

When the toggle switch is held in the DOWN position,

the gas solenoid valve is energized but neither the

power source nor the drive motor will be energized.

While the Gas Purge button is activated, the flow rate

of the Shielding gas can be adjusted. See the “Flow

meter “ section below.

SPINDLE BRAKE

Adjust the spindle brake tension to allow the spool to

spin freely, yet have enough resistance for little or no

overrun when wire feeding is stopped.

FLOW METER

The flowmeter shows the flow rate of shielding gas

and has a valve to adjust the flow. It is calibrated in

Standard Cubic Feet per Hour (SCFH) for CO2, Ar,

and CO2/Ar blends.

The flow rate may be adjusted by turning the valve at

the top of the meter. Most weld procedures require

25-40 scfh (11.8 - 18.9 Liters/Hour) for sufficient

shielding gas coverage. Gun angle, nozzle diameter,

joint configuration and wind conditions may effect the

amount of shielding gas required. To convert (SCFH)

to Liters/Hour multiply SCFH value by .472.

SCFH

Liter/Hour

10

4.7

20

9.4

30

14.2

40

18.9

50

23.6

60

28.3

70

33.1

80

37.8

SHIELDING GAS CONNECTION

CYLINDER may explode if

damaged.

•

Keep cylinder upright and

chained to support.

•

Keep cylinder away from areas where it may be

damaged.

•

Never lift welder with cylinder attached.

•

Never allow welding electrode to touch cylinder.

•

Keep cylinder away from welding or other live

electrical circuits.

-----------------------------------------------------------------------

WARNING