Installation, Input fuse and supply wire, Output connections – Lincoln Electric IM592 INVERTEC V200-T User Manual

Page 10

A-3

INSTALLATION

INVERTEC V200-T

A-3

a) A metal underground water pipe in direct con-

tact with the earth for ten feet or more.

b) A 3/4” (19mm) galvanized pipe or a 5/8” (16mm)

solid galvanized iron, steel or copper rod driven

at least eight feet into the ground.

The ground should be securely made and the ground-

ing cable should be as short as possible using cable

of the same size as the work cable, or larger.

Grounding to the building frame electrical conduit or a

long pipe system can result in re-radiation, effectively

making these members radiating antennas.

6. Keep cover and all screws securely in place.

7. Electrical conductors within 50 ft (15.2m) of the

welder should be enclosed in grounded rigid metal-

lic conduit or equivalent shielding, wherever possi-

ble. Flexible metallic conduit is generally not suit-

able.

8. When the welder is enclosed in a metal building,

the metal building should be connected to several

good earth driven electrical grounds (as in 5 (b)

above) around the periphery of the building.

Failure to observe these recommended installation

procedures can cause radio or TV and electronic

equipment interference problems and result in unsat-

isfactory welding performance resulting from lost high

frequency power.

INPUT CONNECTIONS

Be sure the voltage, phase, and frequency of the input

power is as specified on the rating plate, located on

the rear of the machine.

Supply line entry provision is in the case rear panel.

A power cord is provided and wired into the machine.

Follow the power cord connection instructions.

Incorrect connection may result in equipment damage.

The Invertec V200-T is internally connected for a 460

volt input. The input switch has a lock pin which restricts

movement for 460 selection only. See figure A.1.

To connect the V200-T for 230 volt input, the following

input reconnect needs to be completed.

1. Disconnect the machine from the input supply.

2. Remove the wraparound by removing the shoul-

der strap brackets and wraparound screws.

3. Provide access to the line switch by bending the

insulation back.

4. When the insulation is bent back, two sleeved

leads will become visible.

5. Remove the sleeving from both leads.

6. Connect the large lead to push-on terminal

labeled “3” on the adjacent PC board.

7. Connect the small lead to terminal 15 of the line

switch.

8. Reposition insulation to cover line switch.

9. Re-install wraparound.

10. Move the lock pin to allow switch movement for

230 V selection only.

Connect the green w/ yellow strip lead to ground per

U.S. National Electrical Code. Connect the black and

white leads to power.

Use reverse procedure to reconnect for 460V. Do not

connect 460V when the switch is configured for 230V

or damage will result.

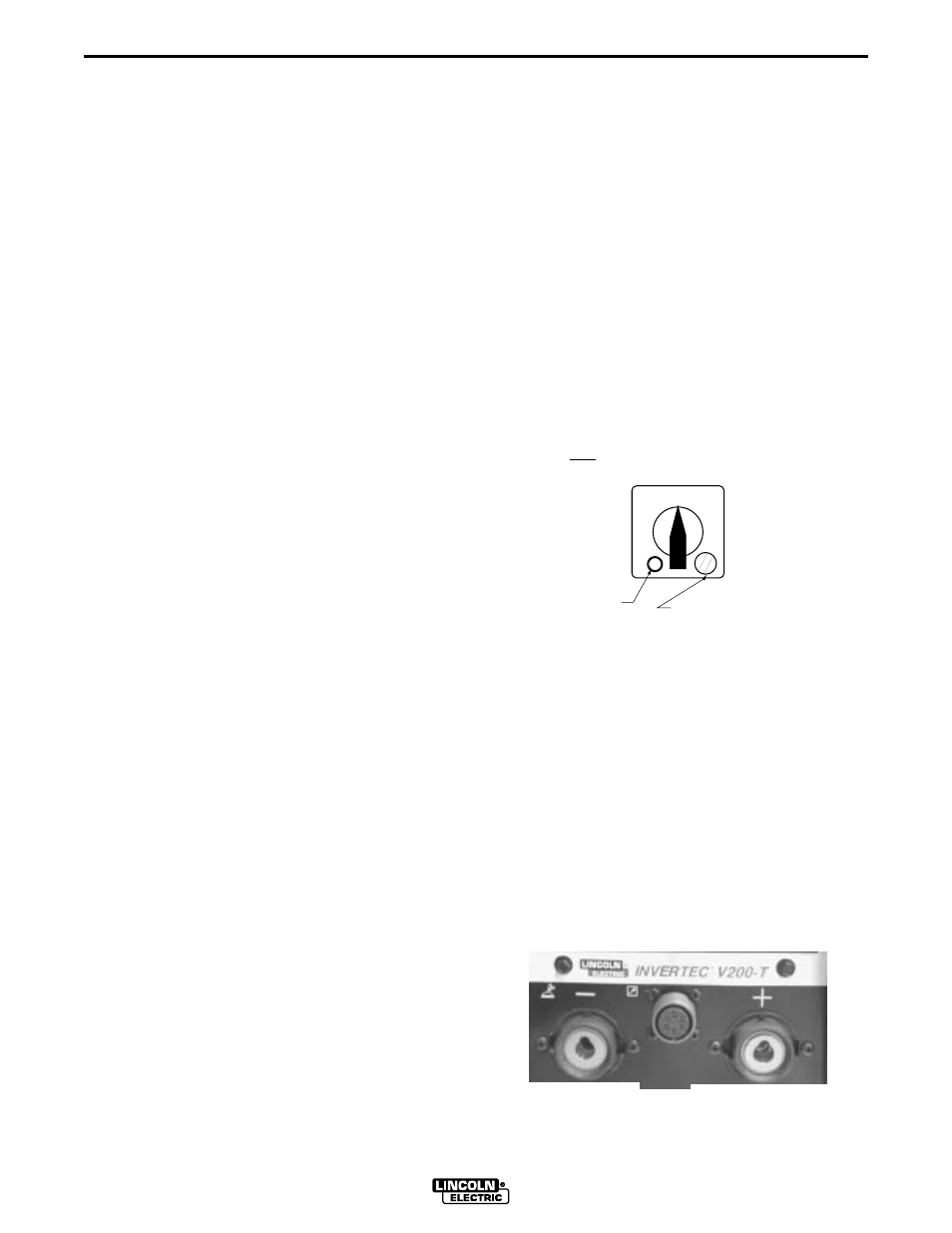

Figure A.1

INPUT FUSE AND SUPPLY WIRE

Refer to the

Technical Specifications pages at the

beginning of this chapter for the proper fuse sizes and

supply cable sizes.

• Fuse the input circuit with recommended super lag

fuses or delay type circuit breakers.

• Install the proper fuse in the fuse holder in the main

disconnect panel.

OUTPUT CONNECTIONS

Figure A.2

230

460

0

Power ON-OFF/Voltage Selector Switch - Located on top right of rear panel

Lock pin mounting hole

Lock pin - in this position allows only

230 V input selection Move to opposite

side for 460 V operation.

TIG TORCH/GAS OUTLET

RECEPTACLE

WORK CABLE RECEPTACLE