Troubleshooting, Caution – Lincoln Electric IM318 IDEALARC DC1500 User Manual

Page 19

E-3

TROUBLESHOOTING

E-3

IDEALARC

®

DC-1500

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

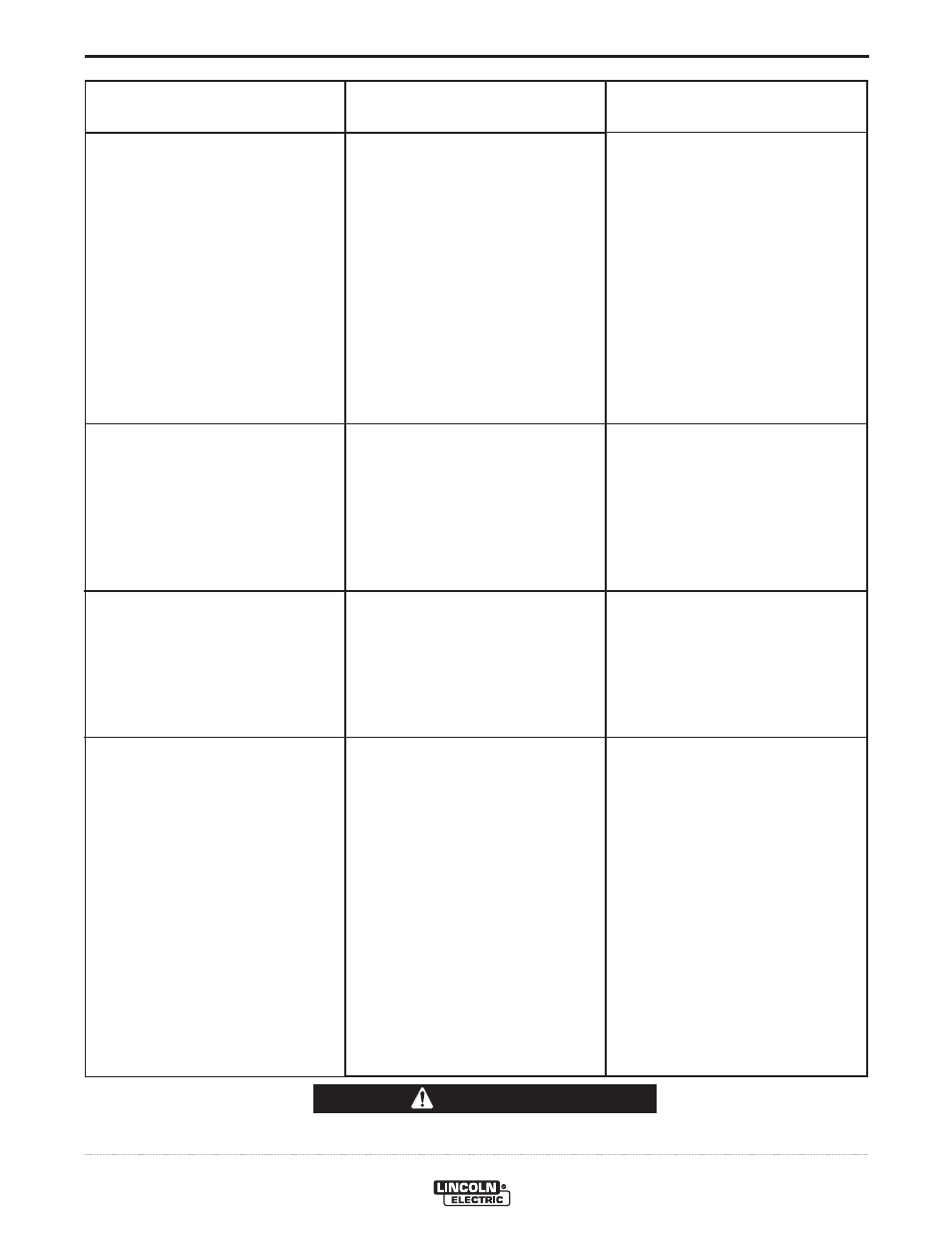

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Machine does not have maximum

output.

Machine has output but trips off

immediately.

Variable or sluggish welding arc.

Machine will not shut off.

1. One input fuse blown.

2. One phase of main transformer

open.

3. Faulty “Control/Fault Protection”

or “Firing Circuit” P.C. boards.

4. Output control potentiometer

defective.

5. Output control potentiometer

leads open 226, 237, 236, 73, 74,

76, 77.

1. Machine has either an internal or

external short circuit on the out-

put.

2. Faulty “Control/Fault Protection”

P.C. board.

3. Machine output voltage applied to

control leads.

1. Poor work or electrode connec-

tion.

2. Welding Cables too small.

3. Welding current or voltage too

low.

1. Input contacts frozen.

2. Pilot relay contacts stuck closed.

1. Check and replace if blown after

checking for reason for blown

fuse.

2. Check for open and repair.

3. All light emitting diodes must be lit

on both P.C. boards, except L4

on “Control/Fault Protection”

board.(See “P.C. Board

Troubleshooting Guide.”)

4. Check and replace if faulty.

5. Check and repair broken leads.

1. Check internally and externally for

any shorts and remove or repair.

2. If no short circuits, LED L4 must

be lit (See “P.C. Board

Troubleshooting Guide”).

3. Check control cable or wire feed-

er for shorted or grounded control

leads.

1. Check and clean all connections.

2. Check Suggested Copper Cable

Sizes in the table of the Instalation

Section.

3. Check procedures for recommend-

ed settings.

1. Check for approximately .13 inch

over travel of contacts.

2. Check and replace if necessary.