Installation instructions (4-roll feeders), Warning – Lincoln Electric IM638 Clutched Aluminum Drive Roll Kits K1682 User Manual

Page 4

KP1682 CLUTCHED ALUMINUM DRIVE ROLL KITS

4

INSTALLATION INSTRUCTIONS

(4-ROLL FEEDERS)

1. Turn off input power to the welding power source

using the disconnect switch at the fuse box before

installing the clutch drive system.

2. Remove the gun and cable, drive rolls, and guide

tubes from the feeder.

3. Remove the hex head screw, clamping collar, and

key from the drive shafts. Save these parts as they

will be required if this feeder is used for normal

operation.

4. Clean and polish the drive shaft on the outgoing

side of the gearbox using a fine abrasive cloth (400

grit). The drive roll must be able to spin freely.

5. Remove both idle rolls from the swing arms by

removing the pins and the socket head cap screws

and washers on the top and bottom of the swing

arms. Save the pins and hardware for later reuse.

(See Figure 4).

Figure 4

Note: All the parts that were removed from the feeder

should be saved. These parts are required for

normal operation. Now the system is ready to

mount all parts of the clutched drive roll system.

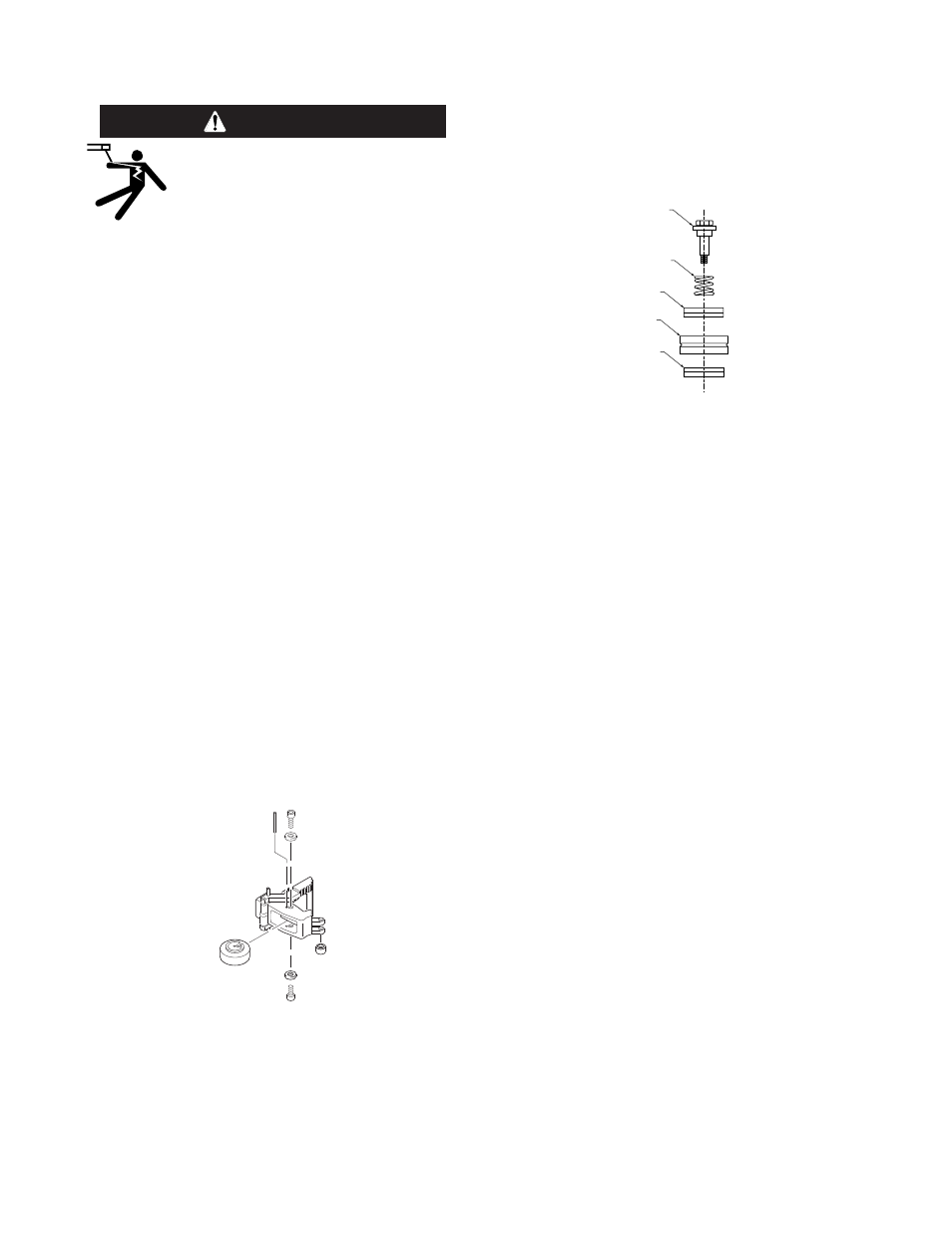

6. As shown in Figure 5, mount the bottom clutch pad,

the drive roll, the top clutch pad, and the spring/bolt

assembly to the feeder’s outgoing side drive shaft.

DO NOT OVERTIGHTEN THE BOLT. Only snug it

to secure the assembly. The proper tension is pre-

set for the wire size and does not need adjustment.

Make sure that the clutch material faces the drive

roll.

Figure 5

7. Mount the long incoming guide tube and the outgo-

ing guide tube into their respective mounts. Do not

overtighten the thumb screw as it may damage the

guide tubes.

8. Install the grooved idle roll in the outgoing side

swing arm using the pins and hardware from Step 5.

9. Mount a new Magnum gun and cable with a fresh

liner designed specifically for aluminum. Page 5

contains recommended liners and tips for standard

Magnum guns.

10. Be certain that the guide tube do not touch the

drive roll or the idle roll. If they do touch, readjust

them and tighten in place.

ELECTRIC SHOCK Can Kill

• Only qualified persons should perform

this installation.

• When inching the electrode, the drive mechanism

and the electrode may be electrically "hot".

• Dirt that accumulates on the wire can be forced into

the feeder and welding gun creating feeding resis-

tance. Maintaining a clean feeder and a clean wire

supply will minimize feeding problems.

------------------------------------------------------------------------

WARNING

yyy

yyy

Bolt

Drive Roll

Top

Clutch

Pad

Bottom

Clutch

Pad

Spring