Installation – Lincoln Electric IM743 INVERTEC V350-PIPE User Manual

Page 10

A-3

INSTALLATION

A-3

V350-PIPE

LN-7 Connection Instructions

•

Turn the Invertec power switch "off".

•

Connect the K480 control cable from the LN-7 to the

115VAC 14-pin wire feeder MS-style connector on the

rear of the Invertec.

•

Connect the electrode cable to the output terminal of

the polarity required by electrode. Connect the work

lead to the other terminal.

•

Set the meter polarity switch on the front of the Invertec

to coincide with wire feeder polarity used. The wire

feeder will now display the welding voltage.

•

If K480 is not available, see connection diagram

S19404 for modification of K291 or K404 LN-7 input

cable with K867 Universal Adapter Plug.

•

If a remote control such as K857 is to be used with the

LN-7, the remote can be connected directly to the 6-pin

MS-style connector on the front of the Invertec or use a

K864 adapter to connect the LN-7 and the remote to

the 115VAC 14-pin MS-style connector on the rear of

the Invertec. (See connection diagram S19901)

LN-10 Connection Instructions

•

Turn the Invertec power switch "off"

•

Connect the K1505 control cable from the LN-10 to the

Invertec 24/42VAC 14-pin MS-style connector on the

rear of the Invertec.

•

Connect the electrode cable to the output terminal of

polarity required by the electrode. Connect the work

lead to the other terminal.

•

Set the meter polarity switch on the front of the Invertec

to coincide with wire feeder polarity used.

•

See the LN-10 manual for details on accessing Control

DIP Switch

LN-742 Connection Instructions

•

Turn the Invertec power switch "off"

•

Either a K591 or a K593 Input cable assembly is

required to connect the LN-742 to the Invertec.

•

Connect the control cable from the LN-742 to the

24/42 VAC 14-pin wire feeder MS-style connector

on the rear of the Invertec.

•

Connect the electrode cable to the output terminal

of the polarity required by electrode. Connect the

work lead to the other terminal.

•

Set the meter polarity switch on the front of the

Invertec to coincide with wire feeder polarity used.

The wire feeder will now display the welding volt-

age.

•

If a remote control such as K857 is to be used with the

LN-742, the remote can be connected directly to the 6-

pin MS-style connector on the front of the Invertec or use

a K864 adapter to connect the LN-742 and the remote to

the 24/42VAC 14-pin wire feeder MS-style connector on

the rear of the Invertec.

Cobramatic Connection Instructions

•

Turn the Invertec power switch "off"

•

Connect the control cable from the Cobramatic to

the 24/42 VAC 14-pin wire feeder MS-style con-

nector on the rear of the Invertec.

•

Connect the electrode cable to the output terminal

of the polarity required by electrode. Connect the

work lead to the other terminal.

•

Set the meter polarity switch on the front of the

Invertec to coincide with wire feeder polarity used.

•

If a remote control such as K857 is to be used with

the Cobramatic, the remote can be connected

directly to the 6-pin MS-style connector on the front

of the Invertec or use a K864 adapter to connect

the cobramatic and the remote to the 24/42VAC

14-pin wire feeder MS-style connector on the rear

of the Invertec.

LN-23P Connection Instructions

1. Shut the welder off.

2. Connect the LN-23P as per instructions on the

appropriate connection diagram in Section F.

(NOTE): When connecting an LN-23P to the

Invertec.

3. Set the "VOLTMETER" switch to "-".

4. Set the "MODE" switch to "CV WIRE" position.

5.

Set the "WELD TERMINALS" switch to

"REMOTELY CONTROLLED".

6. Set the "ARC CONTROL" knob to "0" initially and

adjust to suit.

General Instructions for Connection of Wire

Feeders to V350-PIPE

Wire feeders other than those listed above may be

used provided that the auxiliary power supply rating of

the V350-PIPE is not exceeded. K867 universal

adapter plug is required. See connection diagram

S24985 on page F-4.

REMOTE CONTROL OF INVERTEC

Remote Control K857, Hand Amptrol K963 and Foot

Amptrol K870.

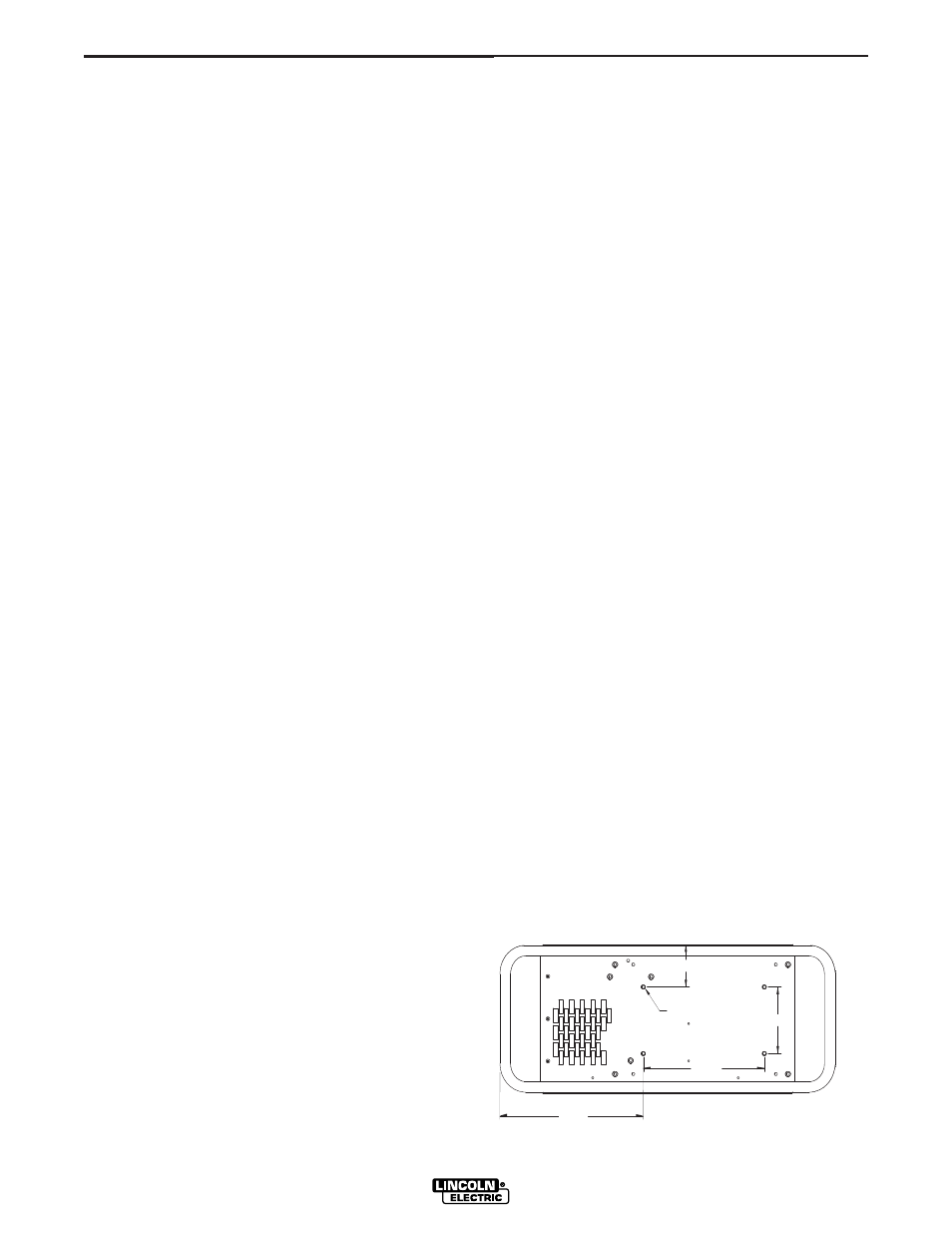

UNDERCARRIAGE MOUNTINGS

5.50

10.00

MOUNTING HOLE LOCATIONS

M19527

1/4-20 NUT (4 PLACES)

NOTE: MOUNTING SCREWS CA

8/00

N NOT PROTRUDE MORE THAN

0.5 INCHES INSIDE THE MACHINE.

11.84

3.50