Operation, Power source operation, Warning – Lincoln Electric IM655 RED-D-ARC DC-400 User Manual

Page 22

B-6

OPERATION

B-6

POWER SOURCE OPERATION

Duty Cycle and Time Period

The DC-400 is rated at the following duty cycles:

* Based upon 10 minute time period (i.e., for 60% duty

cycle, it is 6 minutes on and 4 minutes off).

Overloading the DC-400 may result in opening of an

internal protective thermostat as indicated by the

amber thermal protection light turning on.

STARTING THE MACHINE

The POWER toggle switch at the extreme right side of

the control panel in the

“

I

“

position energizes and clos-

es the three phase input contactor from a 115 volt

auxiliary transformer. This in turn energizes the main

power transformer.

The machine is de-energized when the POWER

switch is in the

“

0

”

position.

The white light below the POWER switch indicates

when the input contactor is energized.

OUTPUT CONTROL DIAL

The OUTPUT control to the right of the center of the

control panel is a continuous control of the machine

output. The control may be rotated from minimum to

maximum while under load to adjust the machine out-

put.

The machine is equipped with line voltage compensa-

tion as a standard feature. This will hold the output

constant except at maximum output of the machine,

through a fluctuation of ±10% input line voltage.

OUTPUT CONTROL

“

LOCAL-REMOTE

”

SWITCH

©

The OUTPUT CONTROL toggle switch on the control

panel labeled

“

LOCAL-REMOTE

”

gives the operator

the option of controlling the output at the machine

control panel or at a remote station. For remote con-

trol, the toggle switch is set in the

“

REMOTE

”

position

and controlled at the wire feed unit control, or by con-

necting a K775 control to terminals 75, 76, and 77 on

the terminal strip at the front of the machine, or by

connecting a K857 control to the 14-pin connector on

the front of the machine. For control at the machine

control panel, the toggle switch is set in the

“

LOCAL

”

.

(Exception: When used with an LN-9, LN-9 GMA or

NA-5 wire feeder, the OUTPUT CONTROL switch

must be in the

“

REMOTE

”

position or automatic shut-

down of the LN-9 or NA-5 may occur.)

POLARITY SELECTION

Polarity selection is made by appropriately connecting

the electrode and work welding cables to either the

“

+

”

stud or to the

“

-

”

stud. Select

“

VOLTMETER

”

switch for

“

+

”

or

“

-

”

electrode for the remote (#21)

work sensing lead.

VOLTMETER SWITCH

Select

“

+

”

for positive electrode or

“

-

”

for negative

electrode polarity for the remote (#21) work sensing

lead of automatic or semiautomatic equipment.

THERMAL PROTECTION LIGHT

The amber thermal protection light will be lit if either of

the two protective thermostats have opened. The out-

put power will be disabled but input power will still be

applied to the welder. (Refer to Machine and Circuit

Protection section).

MODE SWITCH

The large MODE SWITCH on the left side of the

machine, labeled

“

Constant Voltage (Submerged Arc),

Constant Voltage (FCAW/GMAW) and Constant

Current (Stick/TIG)

”

, is used to select the proper

welder characteristics for the process being used.

The CV (FCAW/GMAW) Mode permits the DC-400 to

produce essentially a flat output characteristic that can

be varied from approximately. 12 to 42 volts.

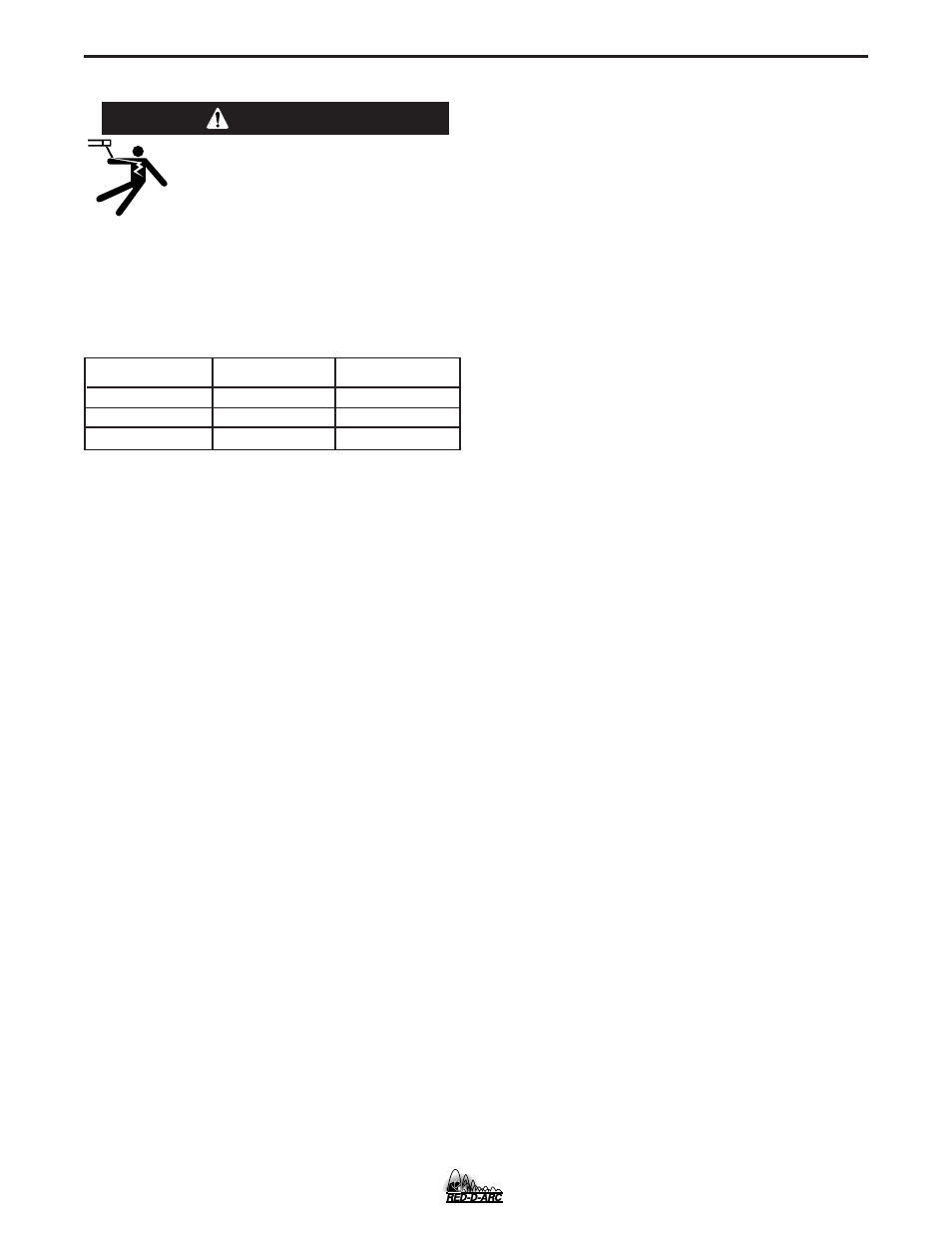

DC-400

DUTY CYCLE *

AMPS

VOLTS

100%

60%

50%

400

450

500

36

38

40

ELECTRIC SHOCK

can kill.

•

Have an electrician install and service

this equipment.

•

Turn the input power off at the fuse

box before working on equipment.

•

Do not touch electrically hot parts.

---------------------------------------------------------------------

WARNING