Motor operation and maintenance, Maintenance instructions, Sealed bearings – Davey ISOSPEC CM Series ISO2858 Heavy Duty Industrial Centrifugal Pump User Manual

Page 5: Open (regreasable) bearings, Recommended lubricant

~ 5 ~

MOTOR OPERATION AND MAINTENANCE

Maintenance Instructions

The following maintenance instructions apply to all SGA

motors except for hazardous location motors. For

SGAE, SGAN and SGAD motors maintenance must

be carried out by an authorized service agent. Contact

CMG for detailed instructions.

To obtain maximum service life from your electric

motor, it is recommended the following maintenance be

implemented and recorded in a plant log book.

A. Ensure air intake space is unobstructed.

B. On a weekly basis use an air hose to ensure all

airways are clear and free of dust.

C. Do not wash the motor down unless it is IP66 rated.

D. On a quarterly basis:-

i) Check motor terminals for tightness and contact.

ii) If terminal lug/lugs are discolored, re-terminate.

iii) Check operation of starting equipment, ensuring

all terminations are tight.

iv) Check mechanical operation of thermal

overload.

v) Check mechanical operation of thermistor relay

(if fitted).

vi) Check operation of space heaters (if fitted).

E. On a six (6) monthly basis, in addition to the items in

‘D’ :-

i) Check stator resistance (compare to original and

enter in log book)

ii) Check supply voltage at motor terminals.

iii) Check bearings for noise/overheating.

F. On an annual basis, in addition to the items in ‘D’

and ‘E’ :-

i) Re-grease bearings in line with chart below.

Note: As indicated in the chart, some bearings

may require more frequent grease replacement.

ii) Strip motor down and clean thoroughly.

iii) Check bearings for wear/damage - replace as

necessary.

iv) Check all machine bolts for cracks or damage

- replace as necessary.

v) Check all holding bolts for signs of fatigue/

damage - replace as necessary.

vi) After re-assembly, check and record:-

Full Load Current

Full Load Voltages

Full Load Speed

vii) Ensure cooling fan is operational.

G. Ensure plant log book records commissioning data

and compare maintenance data with original.

Sealed Bearings

The required replacement interval for sealed bearings

is generally determined by the grease life which is

dependant on operating temperature, operating speed,

the limiting speed of the bearing and the type of grease.

Under normal operating conditions the following

relationship applies:-

n n

log t = 6.54 – 2.6 N – (0.025 – 0.012 N )T

Where:

t = Average grease life (hours)

n = Speed (RPM)

N = Bearing limiting speed with grease lubrication (RPM)

T = Operating temperature (°C)

For further information, please contact your nearest

CMG office for advice.

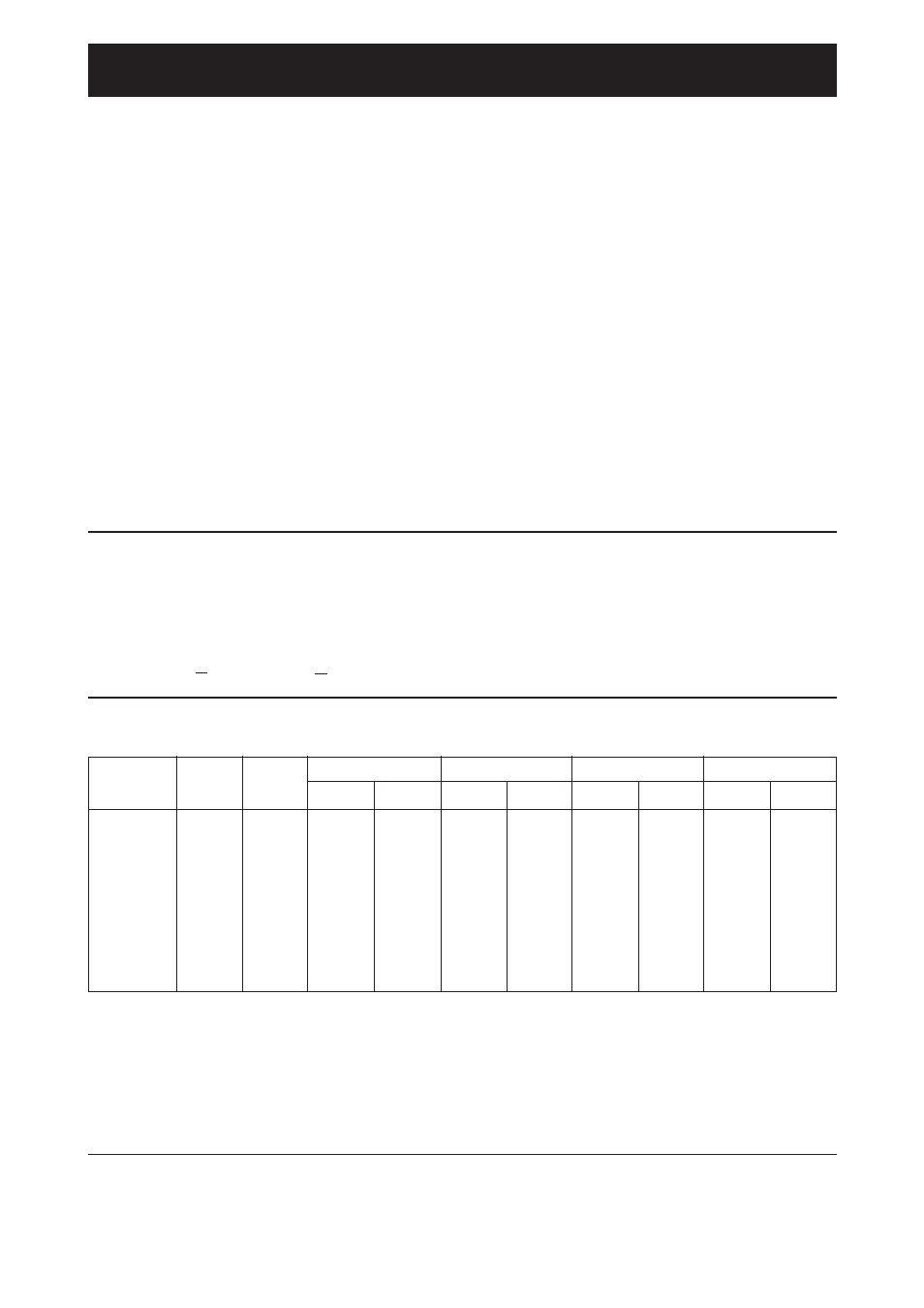

Open (Regreasable) Bearings

Recommended Grease Replenishment Intervals (Hours)

1)

Bearing

Qty of

3000 r/min

1500 r/min

1000 r/min

750 r/min

Bearing

bore

grease

number

[mm]

[g]

Ball

Roller

Ball

Roller

Ball

Roller

Ball

Roller

6312/NU312

60

20

3800

1900

10100

5050

16000

8000

20000

10800

6313/NU313

65

25

3400

1700

9400

4700

15100

7500

20000

10300

6314/NU314

70

30

3000

1500

8800

4400

14300

7150

19500

9750

6315/NU315

75

30

2570

1285

8200

4100

13500

6750

18500

9250

6316/NU316

80

35

2200

1100

7600

3800

12800

6400

17700

8850

6317/NU317

85

40

1800

900

7100

3550

12100

6050

16800

8400

6318/NU318

90

45

1650

825

6600

3300

11500

5750

16000

8000

6319/NU319

95

45

1500

750

5700

2850

9000

4500

14600

7300

6322/NU322

110

60

1200

600

4800

2400

8300

4150

13400

6700

1)

Based on maximum grease service life of 20,000 hours.

It should be noted that for motors fitted with Ball and Roller bearings, the lubrication intervals for both bearings should be

based on the roller bearing data.

The re-lubrication intervals recommended are calculated on the basis of normal working conditions.

Note: Air operated grease guns should

not be used.

Replenishment of grease media should be by means of a hand held grease gun whilst motor is running with relief plate

removed.

Recommended Lubricant

Use Lithium based grease such as Shell Alvania R3 unless otherwise specified. SGAH, SGASS and SGAHS require

extra high temperature grease, Magnalube G or equivalent.