Motor operation and maintenance, Installation, Coupling drive / service – Davey ISOSPEC CM Series ISO2858 Heavy Duty Industrial Centrifugal Pump User Manual

Page 4: Alignment / service, Operation, Number of starts per hour, Permitted starting time

~ 4 ~

Installation

All motors must be installed in such a manner as

to ensure the air intake is not obstructed. Refer to

dimension “BL” in the cooling section of this catalogue.

Bed plates or slide rails should be firmly fixed to a solid,

level foundation to ensure the motor remains rigid and

vibration free. Shims or packers (if required) must be of

adequate size and placed adjacent to and between base

fixings. Protective transport coatings on shafts and/or

flanges must be removed prior to connection to the

driven load.

Coupling Drive / Service

In fitting couplings or pulleys to the motor shaft, care

must be taken to ensure the roller/ball bearings are not

damaged. Tapped holes are provided in shaft extensions

to assist in the fitment of couplings and/or pulleys. Under

no circumstances should couplings and/or pulleys be

impact driven onto the shaft. Couplings or pulleys should

be independently balanced with a half key.

Alignment / Service

Great care must be taken in aligning the complete unit,

since misalignment can cause rapid deterioration of

bearings and lead to other mechanical failures due to

the stress produced. After final tightening of foundation

bolts, machine alignment should be rechecked as bed

plates could distort. No end thrust should be applied to

the motor without express approval.

Operation

Standard motors are designed for a 415 volt (±5% ) 3

phase, 50 Hertz supply. Use of standard motors on

other supply systems should be verified with our office

prior to installation. All units are S1 rated to AS1359 and

associated standards, for operation below 1000 metres

at a maximum ambient temperature of 40°C.

For operation in conditions other than that above please

contact Davey.

Electric motor starting imposes severe thermal stress on

the motor, the frequency of starting should be minimized

to ensure optimum machine life.

MOTOR OPERATION AND MAINTENANCE

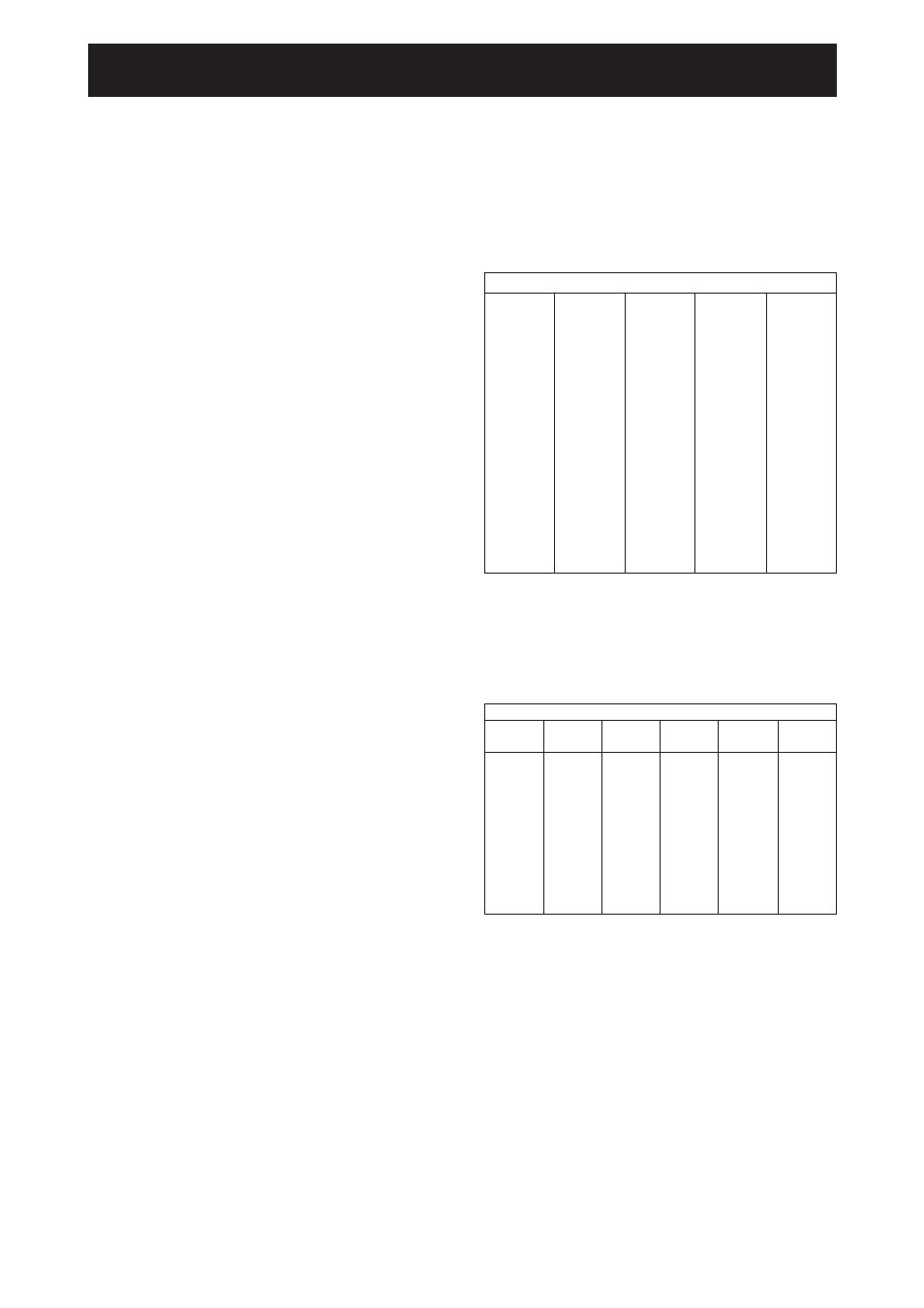

Number of Starts per hour

The number of starts per hour is dependant on the

inertia of the driven load and the load torque demand.

A guide to generally acceptable starts per hour would be

as per table.

For greater number of starts per hour, please contact

Davey.

Starts per hour

Frame

2 pole

4 pole

6 pole

8 pole

71

- 40 - -

80

20

40

40

-

90

16

30

40

-

100

16

30

40

40

112

16

30

40

40

132 10 20 25 25

160

10

20

25

25

180

8

15

20

20

200

6

12

12

12

225

5 10 10 10

250

4

8

8

8

280

3

6

6

6

315 3 4 4 4

Permitted Starting Time

In respect to the temperature rise of the motor, starting

time (i.e., from rest to operational speed) should not

exceed the time indicated in the following table. Motor

must be allowed to cool prior to each start.

Maximum starting time (sec)

Starting

Frame Method 2 pole 4 pole 6 pole 8 pole

71

D.O.L.

-

26

-

-

80

D.O.L.

15

26

40

-

90 D.O.L. 10 15 25 -

100

D.O.L.

12

13

18

40

112

D.O.L.

10

10

18

35

132 D.O.L.

14 12 12 25

160-355 D.O.L.

15

15

20

20

160-355 star-delta

45

45

60

60