Electrical connection, Starting, Structural representation – Davey ISOSPEC CM Series ISO2858 Heavy Duty Industrial Centrifugal Pump User Manual

Page 3: Trouble shooting, Lubrication

~ 3 ~

Electrical Connection

Ensure all electrical connections are solid and

continuous. Check motor starter and overloads for

correct rating and trip setting. All circuit breakers, HRC

fuses or protective devices associated with the motor

must be rated to suit motor running current and starting

characteristics.

Starting

Caution: Do not attempt to run pump if it

has not been filled with water (primed).

Severe damage will result to shaft seal.

1) Ensure the suction line & pump casing is full of water

open suction valve if fitted.

2) Check power is off & rotate the pump shaft slowly to

release any trapped air within the pump casing.

3) Close the discharge valve.

4) Check the direction of rotation on the pump casing or

motor cover.

5) Prior to initial start up, the following steps must be

taken:

• Insulation resistance test. On machines up to 600

volt, the minimum value should be 1MΩ.

• Thermistors if fitted, should be checked for continuity

with a multimeter and never mega-tested.

• Ensure supply voltage and frequency correspond to

the motor nameplate ratings.

• Ensure shaft turns freely before initial start.

• Measure stator resistance and record in Log Book.

6) If this is correct you may now start the pump, when

it reaches full speed you will see the pressure in the

discharge line rise. Slowly open the discharge valve

until the pump adjusts to maintain its duty point.

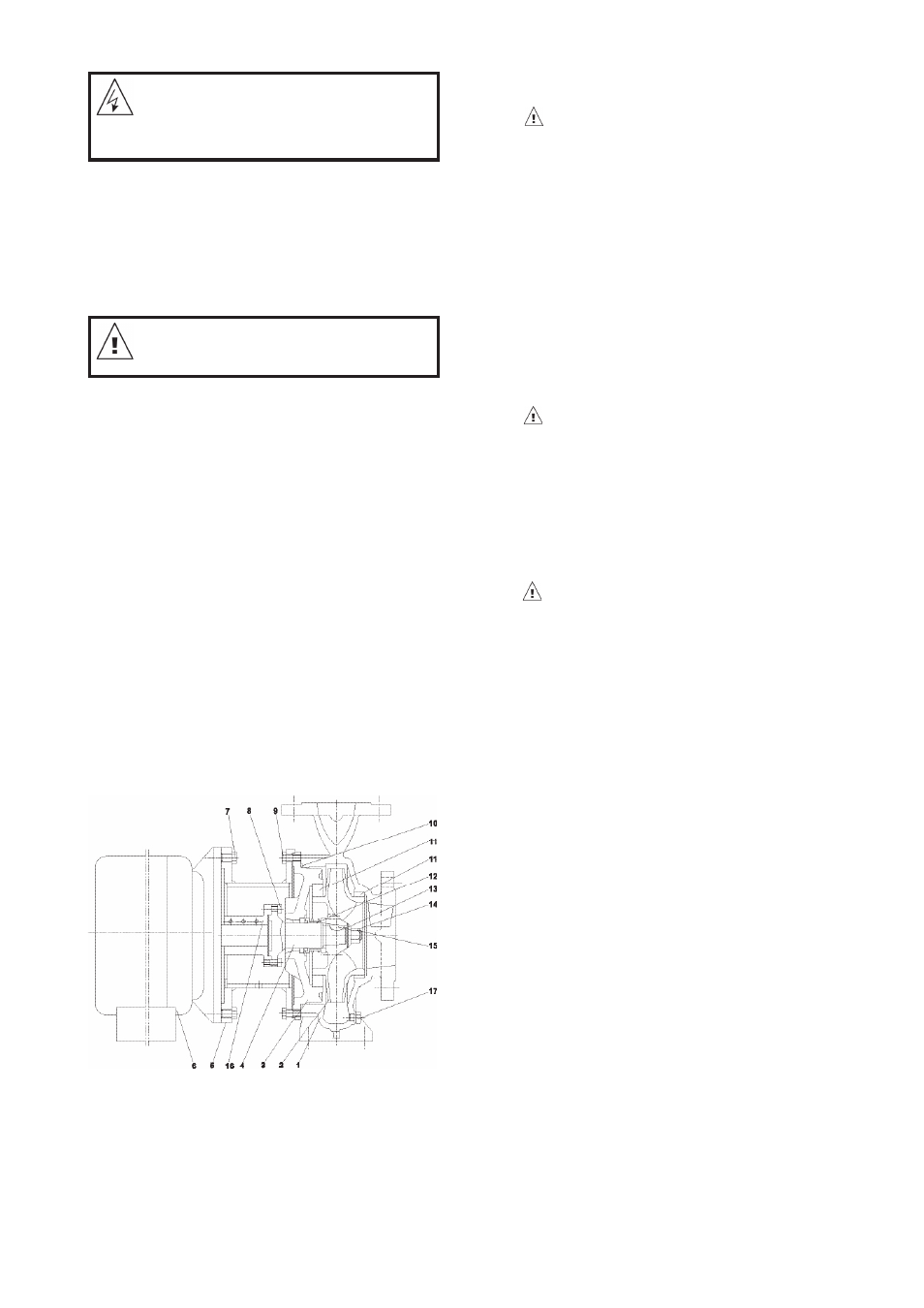

Structural Representation

1. Pump

casing

2. Impeller

3. Rear casing cover

4. Stub shaft

5. Bell housing

6. Motor

7. Bolt

8. Bolt

9. Bolt

10. O-ring

11. Bronze wear ring

12. Mechanical shaft seal

13. Impeller washer

14. Impeller nut

15. Impeller key

16. Muff coupling

17. Volute drain plug

Trouble Shooting

Pump is running but failing to deliver water or

desired pressure.

1)

Turn the unit off.

2)

Check suction line is free of debris or blockages

& check that the pump has not lost its prime. If

so, remove blockage & repeat Starting at step 1).

3)

Check that the suction valve is open.

4)

Check that the discharge valve is open.

5)

Check for air leaks. These may not always be

visible to the naked eye unless pressure is applied

to the suction line.

6)

Check that the suction line is not too long.

7)

Is suction line to pump excessive?

8)

Is the foot valve stuck open or undersized?

9)

Is speed too slow?

10) Check motor direction rotation.

11) Check for possible clogging in impeller vanes

12) Is the discharge piping undersized for

applications.

Excessive Vibration

1)

Turn the unit off.

2)

Check the motor is rotating in correct direction.

3)

Check both motor feet & pump feet are secured

properly.

4)

Check drive coupling is secured tightly to the

motor shaft.

5)

Check motor bearings are OK.

6)

Impeller could be partially blocked causing

imbalance.

Noisy Operation

1)

Turn the unit off.

2)

Check motor bearings.

3)

Check pump is primed.

4)

Check suction line is not damaged, causing

insufficient supply & resulting in cavitation.

5)

Check you are not pumping solids.

High Power Consumption

1)

Check direction of rotation.

2)

Check operating speed on the motor matches the

intended performance curve speed.

3)

Check that the estimated head is correct, as pump

may be running down on its curve, producing high

flow, but drawing more power. Throttle the pump

back on to its curve via discharge gate valve or

reduce impeller diameter.

4)

The Specific Gravity or Density of the liquid is

greater than 1kg/litre affecting power draw.

5)

Check impeller diameter for the correct size, to

establish maximum power requirement at duty

point.

Lubrication

Motor bearings are lubricated with lithium based rolling

contact bearing grease, suitable for operation with-in

the cooling air temperature range of -20

o

C to +55

o

C.

For operation outside this temperature range, special

lubricants are required.

Special lubricants or additional maintenance may be

required in the case of motors exposed to comparatively

high degrees of pollution, high humidity, increased

or changed bearing loads, or prolonged continuous

operation.

WARNING: When installing, servicing or

attending pump, always ensure power is

switched off and lead unplugged. Electrical

connections should be serviced only by

qualified persons. If the electrical supply lead

is damaged, it must be replaced.