Pressure switch settings, Xmp12 adjustments, Flow switch sensitivity adjustment – Davey RAINBANK PRO RAINWATER HARVESTING SYSTEM User Manual

Page 4: Tank precharge, Choosing a site, Power connection

4

CONNECTION OF MAINS SCHEME OR TOWN WATER

SUPPLY TO EITHER SUCTION OR DISCHARGE OF PUMP

Most Water Supply Authorities have strict regulations regarding direct connection of

pumps to mains water supplies. In most cases an isolating storage tank is required

between mains supply and pump — Davey also recommend this method. Directly applied

mains pressure can exceed pump operating pressure and damage pump.

Davey Water Products Pty. Ltd. cannot accept responsibility for loss or damage

resulting from incorrect or unauthorised installations.

PRESSURE SWITCH SETTINGS

Your Davey RainBank

®

PRO pump set should have the correct pressure switch setting

for zero suction lift. If your pump is installed on a suction lift you may need to adjust the

pressure setting to suit.

Any adjustment of the pressure switch settings should be made according to the pump

curve*. The cut-out pressure should never be higher than 90% of the maximum pump

shut head pressure OR higher than the maximum operating pressure for the pressure

tank and the cut-in pressure should be set within the pump curve*. For standard pressure

switch settings refer to the table in the maintenance section of these instructions.

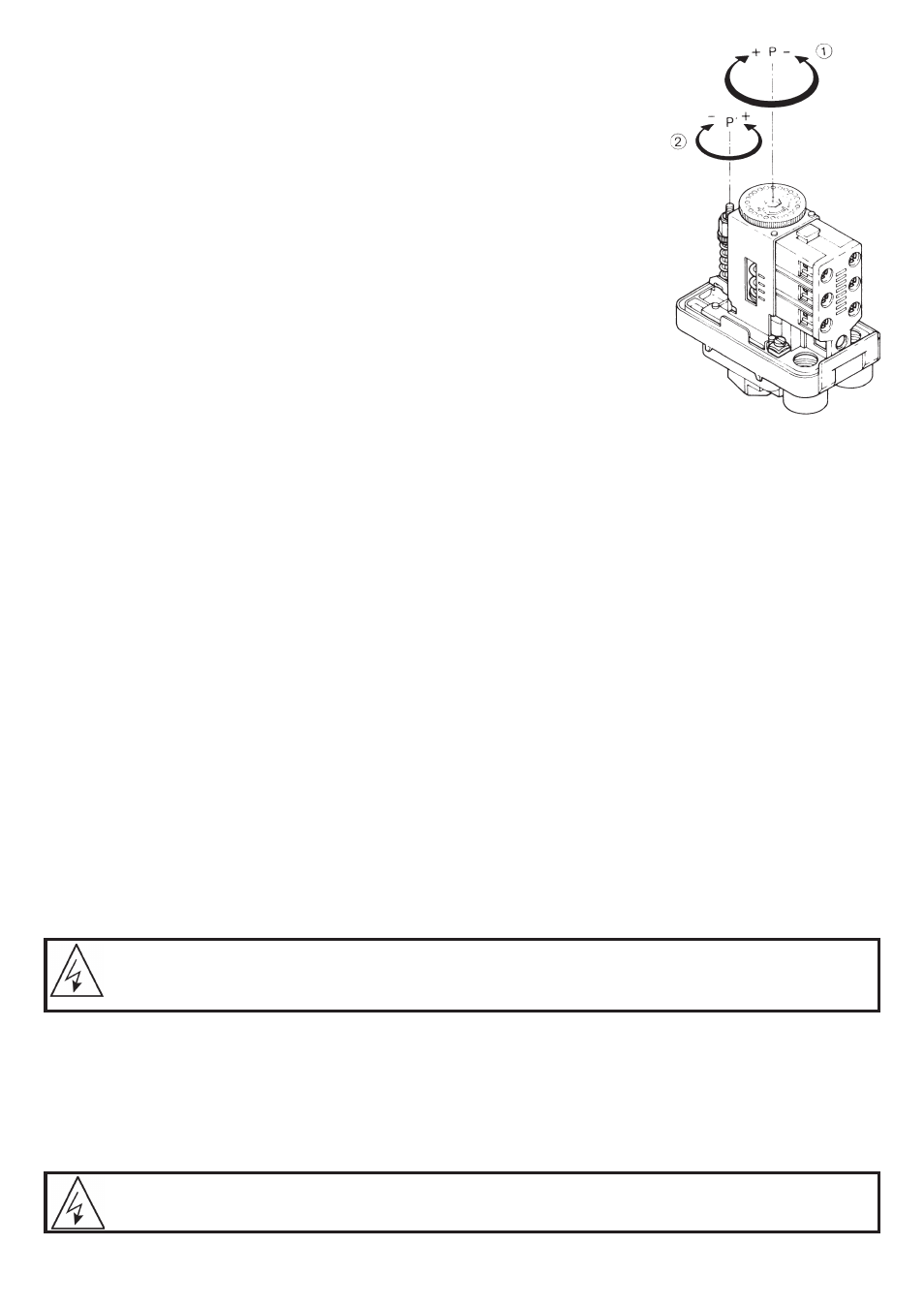

XMP12 Adjustments

To adjust the cut-out (high) pressure of the system, turn the large dial (1) in the desired

direction: + (CW) for higher pressure, – (ACW) for lower pressure.

To adjust the cut-in (low) pressure of the system, turn the smaller screw (2) in the desired direction: + (ACW) for higher

pressure, – (CW) for lower pressure.

FLOW SWITCH SENSITIVITY ADJUSTMENT

There are two methods of setting the point at which the F25 flow switch operates, in relation to any given flow. By far

the most effective is careful trimming of the paddle length. The second method should only be used to fine tune an

installation. There is a sensitivity adjusting screw located at the upstream end of the switch under the end of the electrical

housing. This is accessible by removing the hexagon headed plug, and adjustable using a broad bladed screwdriver. As

supplied, the screw is wound fully in. This setting makes the switch least sensitive to liquid impinging on the paddle. The

screw may be wound anticlockwise, to increase the sensitivity. That is, to make the switch respond to lower flows, or to a

more smaller area of paddle eposed to the flow. The screw should never be removed or wound out more than 6 full turns,

and never wound in beyond its stop. The switch will not operate if the screw is removed.

TANK PRECHARGE

The pressure tank fitted to your Davey pump set should be pre-charged with air to a value of 15kPa below the cut

in pressure. For standard tank pressure settings refer to the table in the maintenance section on page 10 of these

instructions.

CHOOSING A SITE

Choose a site with a firm base and as close to the water source as possible with correct power supply. Make sure your

pressure pump is always connected to an adequate, reliable source of clean water.

Housing your Davey Pump: To protect your pump from the weather, make sure the housing is both water proof and frost

free and has adequate ventilation.

The pump set should be mounted on its base in a firm dry area allowing for drainage, to avoid damage due to flooding

etc., that over time may occur from leaking pipe joints or pump seals.

POWER CONNECTION

Only connect the pump set to the power supply designated on the pump and motor label.

Single-phase pumps up to 1.5kW have a built in thermal overload and have been provided with a 10 amp cable and plug

for connection to a standard power outlet.

Single-phase 2.2kW pumps have a built in thermal overload and have been provided with a 15 amp cable and plug for

connection to a standard 15 amp power outlet.

Do not use long extension leads as they cause substantial voltage drop, poor pump performance and may cause motor

overload.

WARNING: Some insects, such as small ants, find electrical devices attractive for various reasons.

If your pump enclosure is susceptible to insect infestation you should implement a suitable pest

control plan.

The electrical connections and checks must be made by a qualified electrician and comply with

applicable local standards.

* Adjusted for site conditions, i.e. suction

life or positive suction pressure