Water temperature, Maximum start & pressure system installation, Maintenance and service – Davey 6 Submersible Borehole Pumps User Manual

Page 6

6

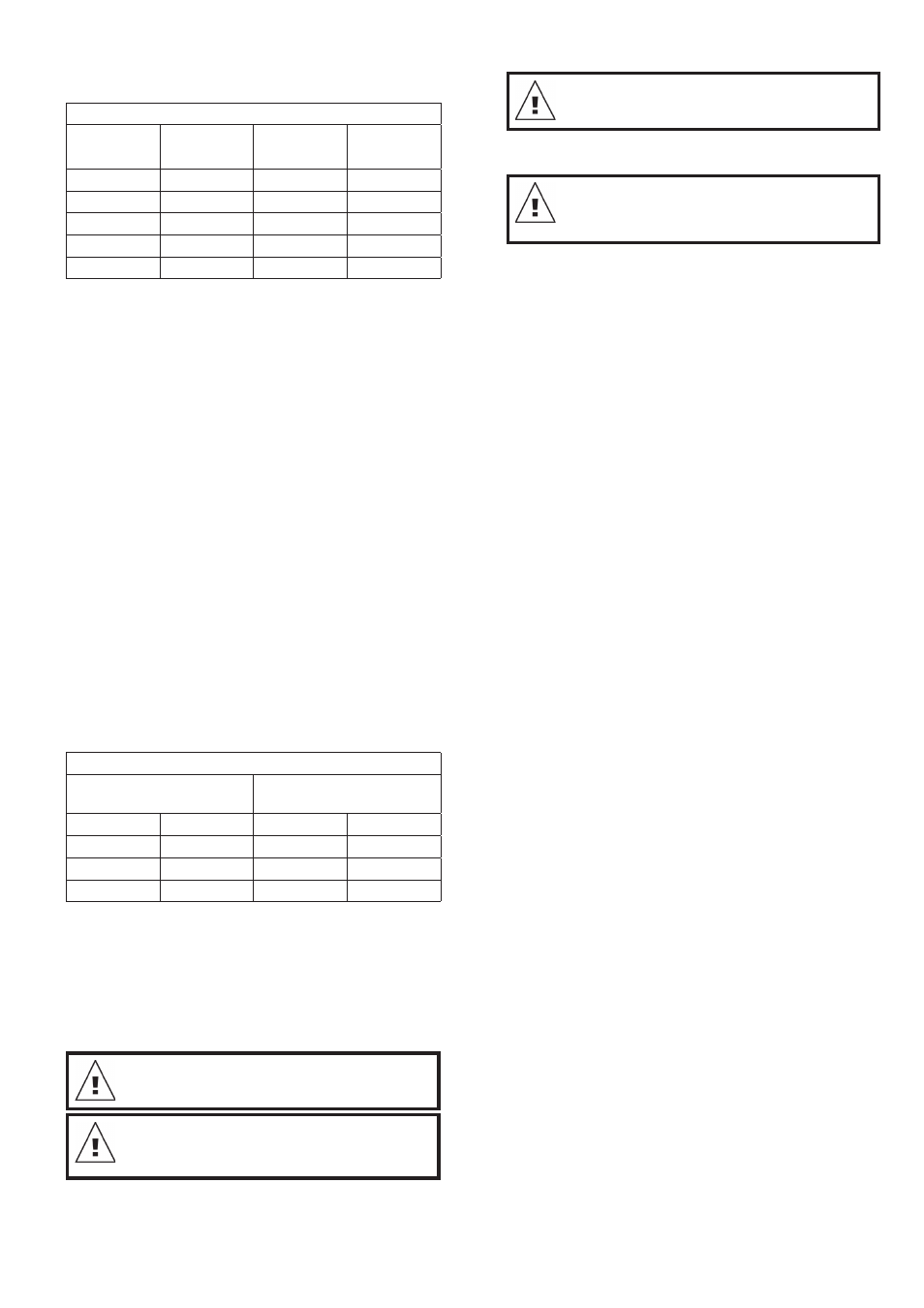

8. Water Temperature

Reduced motor loading in water over 30oC (86oF)

Approximate Allowable % of Maximum Nameplate Amps

Water

Temperature

Through 3 hp

(2.2 kW)

5-15 hp

(3.7-11 kW)

Over 15 hp

(11 kW)

35ºC

100%

100%

90%

40ºC

100%

90%

80%

45ºC

90%

80%

70%

50ºC

80%

70%

60%

55ºC

70%

60%

45%

Do not use submersible motors in water over 55oC

(130oF).

With proper water flow past the motor, submersible

motors are designed to operate up to nameplate

amperage rating in water as hot as 30oC. If the

water temperature exceeds 30oC, reduce the load by

changing pumps or throttling the pump discharge.

9. Maximum Start & Pressure

System Installation

Davey submersible borehole pumps may be used as

a pressure system in conjunction with pressure tanks

providing a suitable draw off capacity.

Caution: The operation of large Submersible units as

automatic pressure systems must be done with great

care.

When selecting a pressure tank, make sure that the

rated tank pressure is at least 10% greater than the

maximum pump pressure at the bore head. Ensure

tank draw off accommodates the least amount of

starts as possible, and does not exceed the number of

starts listed in the following table.

Frequency of Starts

Motor Rating

Average Starts per day

per 24 hour day

kW

hp

Single Phase Three Phase

.75 to 4.0

1 to 5.5

100

300

5.5 to 22

7.5 to 30

100

Over 22

Over 30

100

While small capacity tanks may be used, extreme

care must be taken to ensure the pump unit does

not ‘cycle’. It may be necessary to fit more than one

pressure tank to provide the required draw off or to

help prevent pump cycling.

For further information on these contact your Davey

Dealer.

NOTE: Any automatic switching of the pump giving

excessive starts per hour will shorten the life of the

unit and damage caused may affect guarantee.

WARNING: Failure to use correct starting

equipment and overloads may damage your

Submersible Motor. This damage may not be

covered by guarantee.

Davey supply a range of control boxes incorporating

various switching devices and the use of these

products is recommended.

10. Maintenance and Service

If the pump has been used for a liquid which is

hazardous to health or toxic, the pump will be

classified as contaminated.

10.1 Operation & Maintenance

The pump must not be operated with the delivery

valve shut off (closed head) for more than a few

seconds, otherwise the motor will overheat,

possibly causing permanent damage.

While Davey submersible pumps do not require

regular maintenance, it is a good practice to monitor

the conditions and performance of the pump and

motor. this diagnosis may be carried out by checking

the maximum pressure (shut valve for a very short

period) generated by the pump, and by checking the

amperage draw of the motor at standard duty flow

rate.

Both these figures should be compared to pressures

and current draws recorded when the unit was initially

installed. Any reduction in pressure may indicate

wear in the pump, while any increase in motor current

indicates a possible overload condition. Consult the

pump service chart for further diagnosis of possible

causes.

All pumps are easy to service.

Use only Service kits and tools suitable for

maintenance.

The Service Manual is available on request.