Electrical connection, Pump installation – Davey 6 Submersible Borehole Pumps User Manual

Page 4

4

3.2

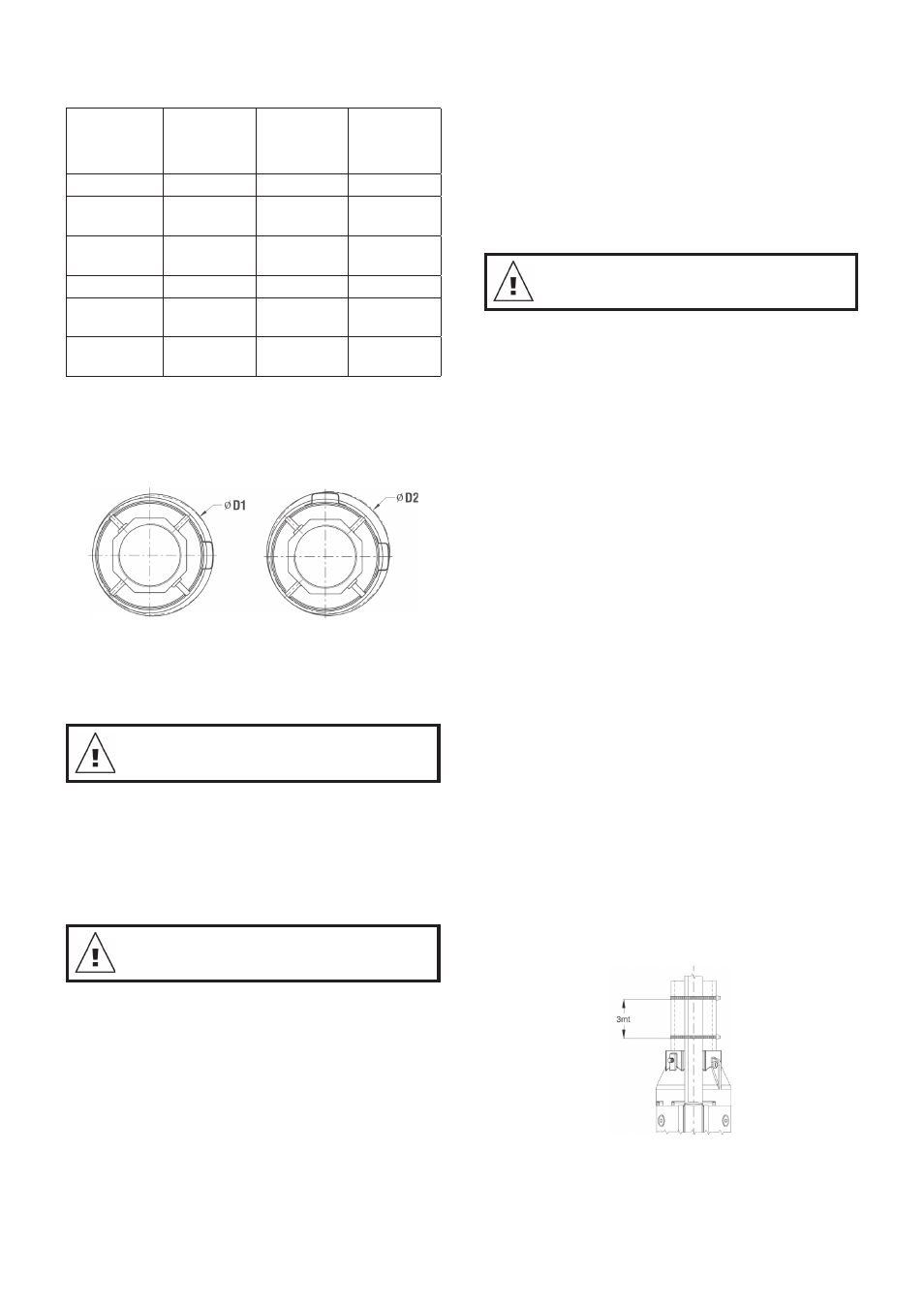

Diameter of Pump/Motor

The maximum diameter of the pump and of the pump

with motor is as shown in the table below:

Diameter

with 1

cable cover

Diameter

with 2

cable covers

External

Motor

Diameter

Pump 6”

141

145

-

Pump 6”

with motor 4”

141

-

95.25

Pump 6”

with motor 6”

144

146.5

136.5

Pump 8”

186.5

192

-

Pump 8”

with motor 6”

186.5

192

136.5

Pump 8”

with motor 8”

195

197.5

187.5

Verify the borehole with an inside calliper to ensure

unobstructed passage.

With

With

Standard Motor

Star Delta Motor

It is recommended to check the borehole with an

inside calliper to ensure unobstructed passage.

4.

Electrical Connection

Before starting work on the pump, make sure that

the electricity supply has been switched off and

that it cannot be accidentally switched on.

4.1 General

The electrical connection should be carried out by

an authorised electrician in accordance with local

regulations. The supply voltage, rated maximum

current and cos appear from the loose data plate

that must be fitted close to the installation site.

The motor must be earthed and connected to an

external mains switch with suitable earth leakage

installed by a qualified electrician.

4.2

Checking of Direction of Rotation

When the pump has been connected to the electricity

supply, determine the correct direction of rotation as

follows.

Prior to installation, manually start the pump unit

for no longer than 2 seconds run time, then turn off.

The unit should be rotating counter clockwise when

looking down onto pump discharge.

If the pump has been installed, please refer to below

steps to determine rotation.

1. Start the pump and check the head developed with

gate the valve partially open.

2. Stop the pump and interchange two of the phase

connections.

3. Start the pump and repeat point 1. with gate valve

in the same position.

4. Stop the pump.

Compare the results taken under points 1. and 3. The

connection which gives the higher head is the correct

connection.

The Pump must not be started until the suction

motor adaptor has been completely submerged in

the liquid.

5. Pump Installation

Before starting any work on the pump/motor, make

sure that the electricity supply has been switched off

and that it cannot be accidentally switched on.

5.1

Assembly of Motor and Pump

Couple the pump and the motor properly along the

same axis and insert the motor shaft in the pump shaft

joint: the coupling must not be forced.

Tighten screws or nuts, screwing up pump-motor

flanges, diagonally with a 100Nm driving torque.

5.2

Riser Pipe

If a tool, e. g. a chain pipe wrench, is used when the

riser pipe is fitted to the pump, the pump must only be

gripped by the pump discharge chamber.

The threaded joints on the riser pipe must all be well

cut and fit together to ensure that they do not work

loose when subjected to torque reaction caused by

the starting and stopping of the pump.

The thread on the first section of the riser pipe which

is to be screwed into the pump should not be longer

than the threads in the pump.

After screwing the riser pipe into the pump inlet,

tighten the screw in the discharge outlet to prevent

loosening of the first section of the riser pipe.

5.3

Cable Fitting

Cable ties must be fitted every 3 metres to fix the

submersible drop cable and the straining wire, if

fitted, to the riser pipe of the pump. Cable fitting: Use

rubber/plastic cable ties. Once fastened, cut off the

remaining part of band.

Fig. 5

Where plastic pipes are used, some slackness must

be left between each cable tie as plastic pipes expand

when loaded. When flanged pipes are used, the cable

ties should be fitted above and below each joint.