Minimum flow requirements – Davey 6 Submersible Borehole Pumps User Manual

Page 5

5

5.4

Lowering the pump

It is recommended to check the well by means of an

inside calliper before lowering the pump to ensure

unobstructed passage. Lower the pump carefully into

the well, taking care not to damage the motor cable.

NOTE: Do not lower or lift the pump by means of

the motor cable.

Fig. 5.4

5.5

Installation Depth

The dynamic water level should always be above the

suction motor adaptor of the pump. The minimum

safety margin should be 1 metre head at the bores

lowest water level. When the pump has been installed

to the required depth, the installation should be

finished by means of a well seal. Slacken the straining

wire so that it becomes unloaded and lock it to the

well seal by means of wire locks.

6. Start-Up

When the pump has been connected correctly and it

is submerged in the liquid to be pumped, it should be

started with the gate valve closed off to approx. 1/3

of its maximum volume of water. Check the direction

of rotation as described in section 4.2 Checking of

Direction of Rotation. If there are impurities in the

water, the valve should be opened gradually as

the water becomes clearer. The pump should not

be stopped until the water is completely clean, as

otherwise the pump parts and the non-return valve

may choke up. As the valve is being opened, the

drawdown of the water level should be checked to

ensure that the pump always remains submerged.

The dynamic water level should always be above the

suction motor adaptor of the pump, see section 3.1

Positional Requirements and fig. 6.

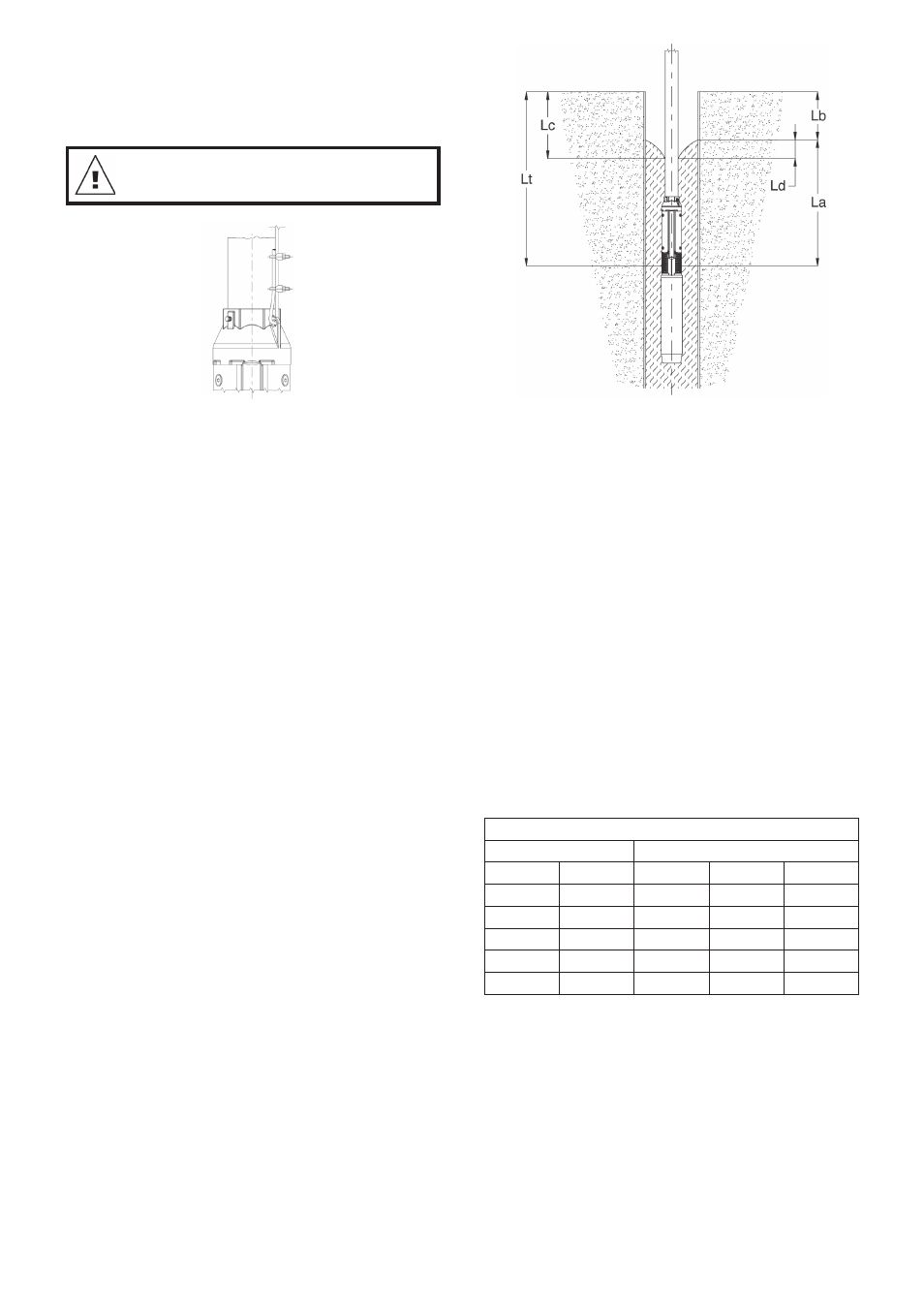

Fig. 6

La: Minimum installation depth.

(suggested: minimum 1 mt)

Lb: Static water level.

Lc: Dynamic water level.

Ld: Difference between static and dynamic level.

Lt: Installation depth.

If the pump can pump more than yielded by the well,

it is recommended to fit a control unit of dry-running

protection.

If no water level electrodes or level switches are

installed, the water level may be drawn down to the

suction motor adaptor of the pump and the pump will

then draw in air.

Long time operation with water containing air may

damage the pump and cause insufficient cooling of

the motor.

7. Minimum Flow Requirements

6” Motors

Bore size

Minimum Flow Rate

Inch

mm

lpm

gpm

m3/hr

8

203.2

170

37.4

10.2

10

254

340

74.9

20.4

12

304.8

530

116.7

31.8

14

355.6

760

167.4

45.6

16

406.4

1060

235

63.6

If flow rate is less than above or water is coming from

above the pump a shroud must be fitted. A shroud is

always required in an open body of water eg. a dam

or river, or a cascading bore.