Stuart Turner LFL Automatic Flow Switch User Manual

Page 9

- 9 -

Cont ...

It must be ensured that the storage capacity of the liquid supply is adequate for the flow

rates required by the pump.

The pipework feed to the storage tank should be of adequate size to ensure

replenishment rate of tank is sufficient to meet the needs of the pump.

The pump must be supplied with a dedicated feed direct from the liquid storage tank.

Isolating valves should be fitted in suction and delivery pipework to enable easy isolation

and access to the pump.

When the pump is to be installed in areas where there is a risk of debris or scale build up

within the system, it is recommended that the inlet pipework is fitted with an inline strainer.

To prevent loss of pressure through pipework, use a pipe size to match pump whenever

possible, minimising 90° bends.

The pipe runs from the pump to the highest outlet should not be routed above the level of

the storage system.

Pipework Connections (Hot Water)

When a hot water cylinder or storage tank is used, ensure the pipework size from the

cold water storage to the hot water storage is of adequate size.

The pump must be supplied with dedicated feed direct from the hot water cylinder.

Pipework Connections (Hot Water)

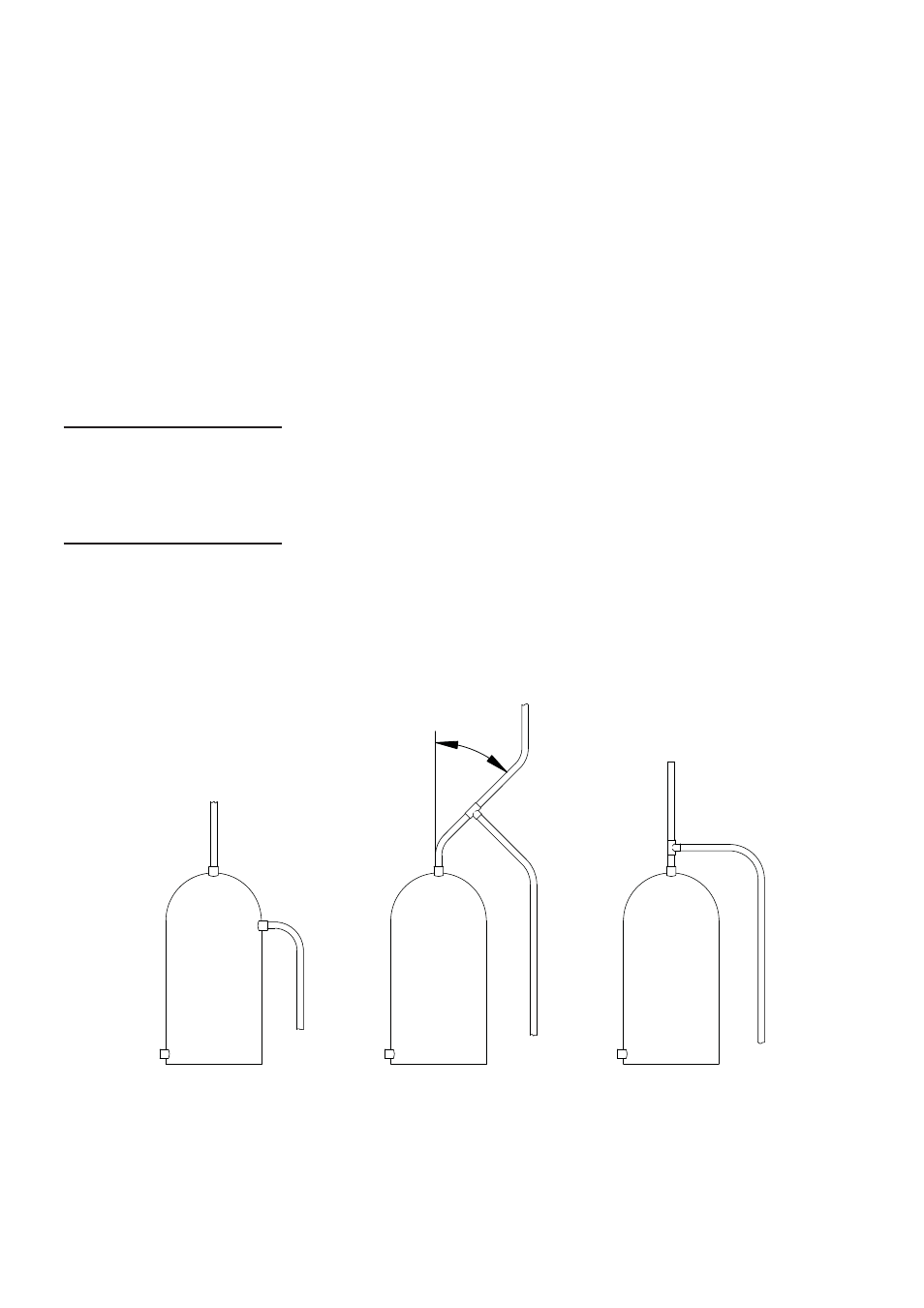

(KFL and LFL range)

These pumps should have a minimum of 28 mm pipework throughout the system.

The supply must be air free and connection to the cylinder can be via an Essex flange or

by one of the following methods shown.

When method of connection is to be via the expansion pipe, the cold water storage

cistern should be at least 1.5 metres above the top of the hot water cylinder.

Fig. 7

45°

Essex flange

28 mm

Off expansion

pipe, off-set

45°, 28 mm

pipework

Off vertical

expansion

pipe, 28 mm

pipework

(As close to the cylinder as possible)