Stuart Turner PH 35 TS User Manual

Page 9

- 9 -

NOISE

The equivalent continuous A-weighted sound pressure level from the pumpset does not

exceed 70 dB(A) at a distance of one metre.

COMMISSIONING

WARNINGS:

The motor casing can become very hot under normal operating

conditions, care should be taken to ensure it cannot be touched

during

operation.

Do not run pump without guards and terminal box lid correctly fitted.

The pump chamber must be full of liquid at all times. Seal damage

will result if the pump runs dry.

1. System

Flushing

Some pumps incorporate plastic and rubber components that must not

come into contact with solder flux, acid-based descalents or aggressive

cleaning agents. The pipework system should be flushed out prior to the

pump being connected, to ensure any contaminants/chemical residues and

foreign bodies are removed from elsewhere in the system.

2. Liquid

Supply

Always ensure that liquid storage capacity is adequate to meet the demand.

Ensure the pump chamber is full of liquid before starting the pump. Failure

to do this could result in seal damage. To ensure dry running does not

occur the pumps must be primed as described in the priming section.

Do

not run pump dry.

3. Ensure electrical supply is compatible with the details that are stated on the pump

rating plate. (The wrong voltage or frequency can be dangerous and may damage

the

pump.)

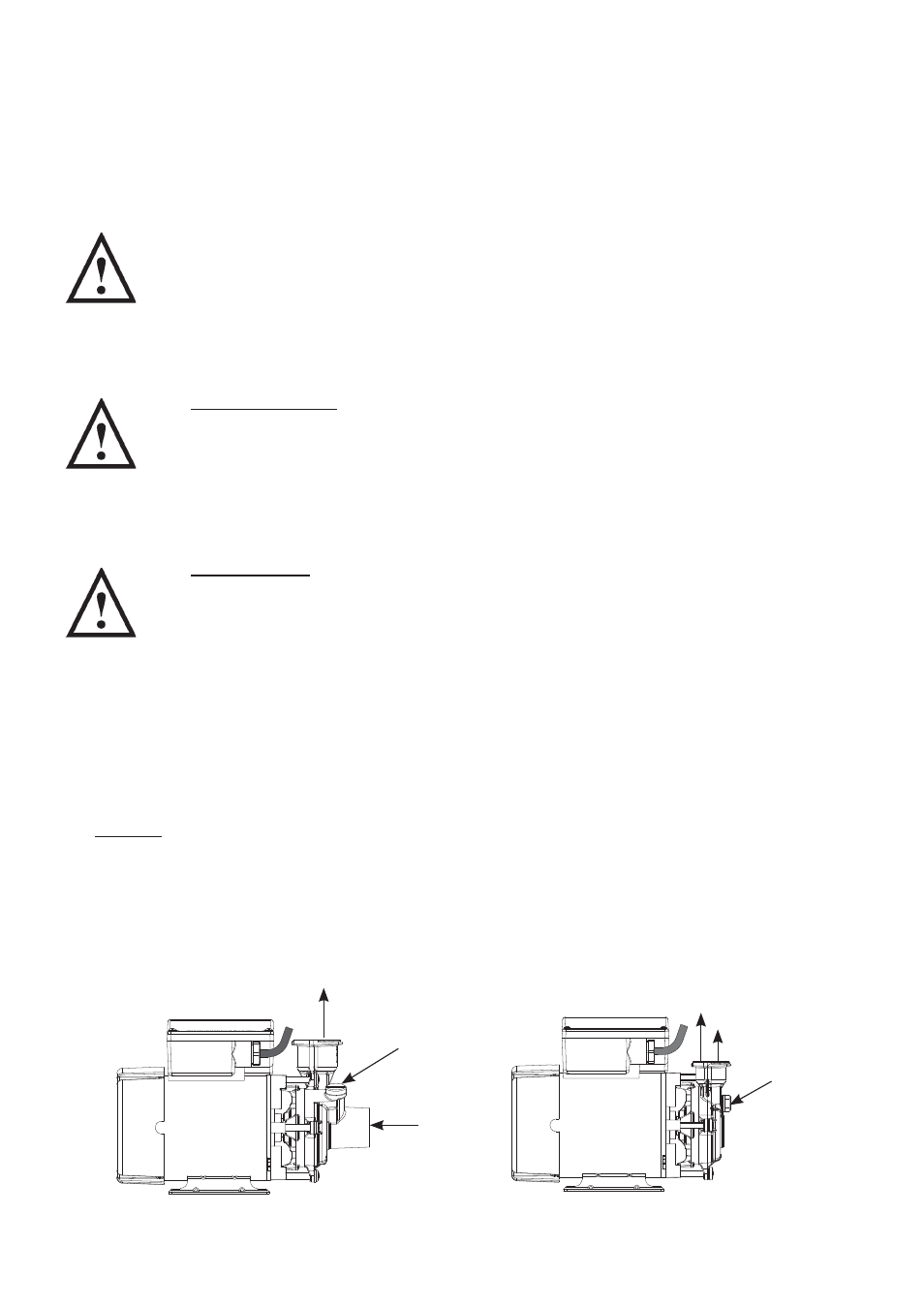

4. Priming

a) End suction models (flooded suction)

These models are supplied with priming plugs fitted.

The pump must be primed (filled with liquid) before starting. Turn on liquid

supply, prime and vent the pump by unscrewing the priming plug (Fig. 6)

slowly until all air escapes and liquid emerges. Re-tighten the plug.

Fig. 6

Inlet

Inlet

Outlet

Outlet

Priming

Plug

Priming

Plug