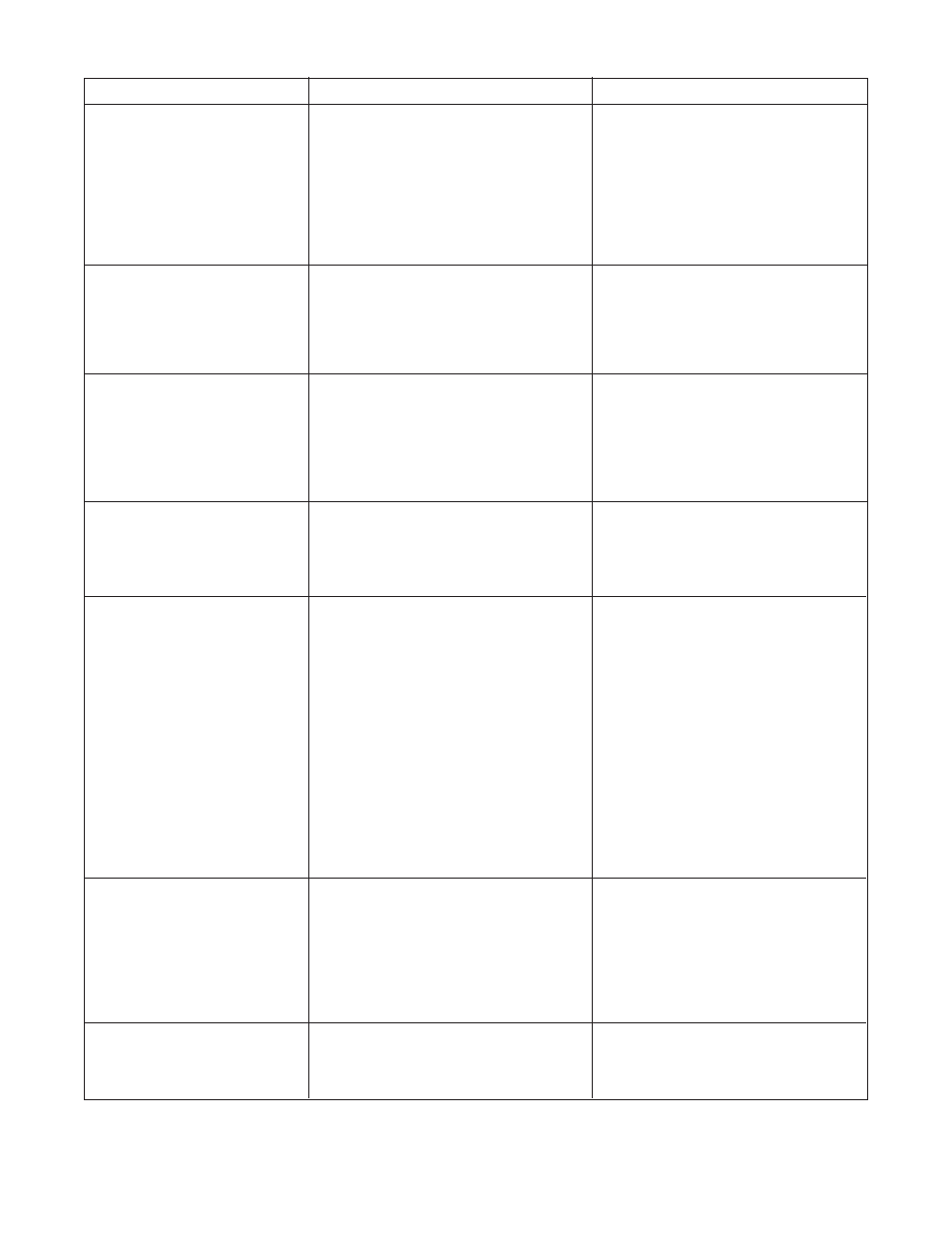

Power vented propellers troubleshooting guide – Sterling QVEF User Manual

Page 21

1. Loose S8600 connections.

2. Improper gas pressure.

3. Is spark in pilot gas stream?

4. No pilot gas — do not use match to

test - presence of gas is easily

detected by the odor.

1. Loose S8600 connections.

2. Cracked or broken sensor ceramic.

3. Check sensor/spark lead for continuity.

4. Measure 24 volts from term. MV to

term.

MV/PV.

1. Vertical run of fl ue is too short.

2. Unit is overfi ring.

3. Air fl ow too low

4. Defective

switch.

1. Power venter wheel loose.

2. Power venter wheel dirty.

3. Power venter wheel rubbing housing.

4. Bearings are dry.

1. Loose

wiring.

2. Defective motor overload protector or

defective

motor.

3. Defective power venter relay.

1. Fan relay heater element improperly

wired.

2. Defective venter relay switch.

3. Motor overload protector cycling on

and

off.

4. Motor not properly oiled.

1. Improperly wired venter relay.

2. Main burners not lighting while

thermostat calls for heat.

3. Defective venter relay.

1. Check all connections, term.

PV feeds 24V to pilot valve.

2. Check pressure — pressure that is

either too high or too low may cause

a

problem.

3. Spark should arc from electrode.

4. Check pilot line for kinks. Ensure

there are no drafts.

1. Check connections-term. MV feeds

main

valve.

2. Replace pilot assembly.

3. Replace if needed.

4. If present, replace main valve; if not,

replace S8600 Igniter.

1. Lengthen vertical run of fl ue pipe

(see

venting).

2. Burner orifi ce may be too large:

verify/replace if req'd.

3. Increase air fl ow; check fan size.

Check for proper voltage.

4. Replace.

1. Replace or tighten.

2. Clean power venter wheel.

3. Realign power venter wheel.

4. Oil bearings on power venter motor.

(Refer to label on motor).

1. Check and tighten all wiring connec-

tions per diagrams. Thermostat wires

tagged "W" and "G" must be

connected together (unless special

thermostats are used; if so, see

thermostat wiring diagram). See

electrical

connections.

2. Replace

motor.

3. Check for 24V across 1 and 3

terminals on fan relay. If 24V is

present, jumper terminals numbered

2 and 4. If motor runs, the relay

is defective and must be replaced.If

24V is not present, check wiring per

diagrams.

1. Be sure venter relay heater terminals

are connected per diagrams.

2. Replace venter relay.

3. Check motor amps against motor

name plate rating, check voltage,

replace power venter motor if

defective.

4. Refer to label on motor.

1. Check all wiring.

2. Refer to H & N symptoms.

3. Replace venter relay.

Power Vented Propellers Troubleshooting Guide

SYMPTOMS

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

W. Spark present but pilot does

not

light.

X. Pilot lights — Main valve

does not energize.

Y. Hi-Limit switch tripping.

Z. Noisy power venter.

AA. Power venter will not run.

BB. Power venter motor turns

on and off while burner is

operating.

CC. Power Ventor motor will not

stop.

21