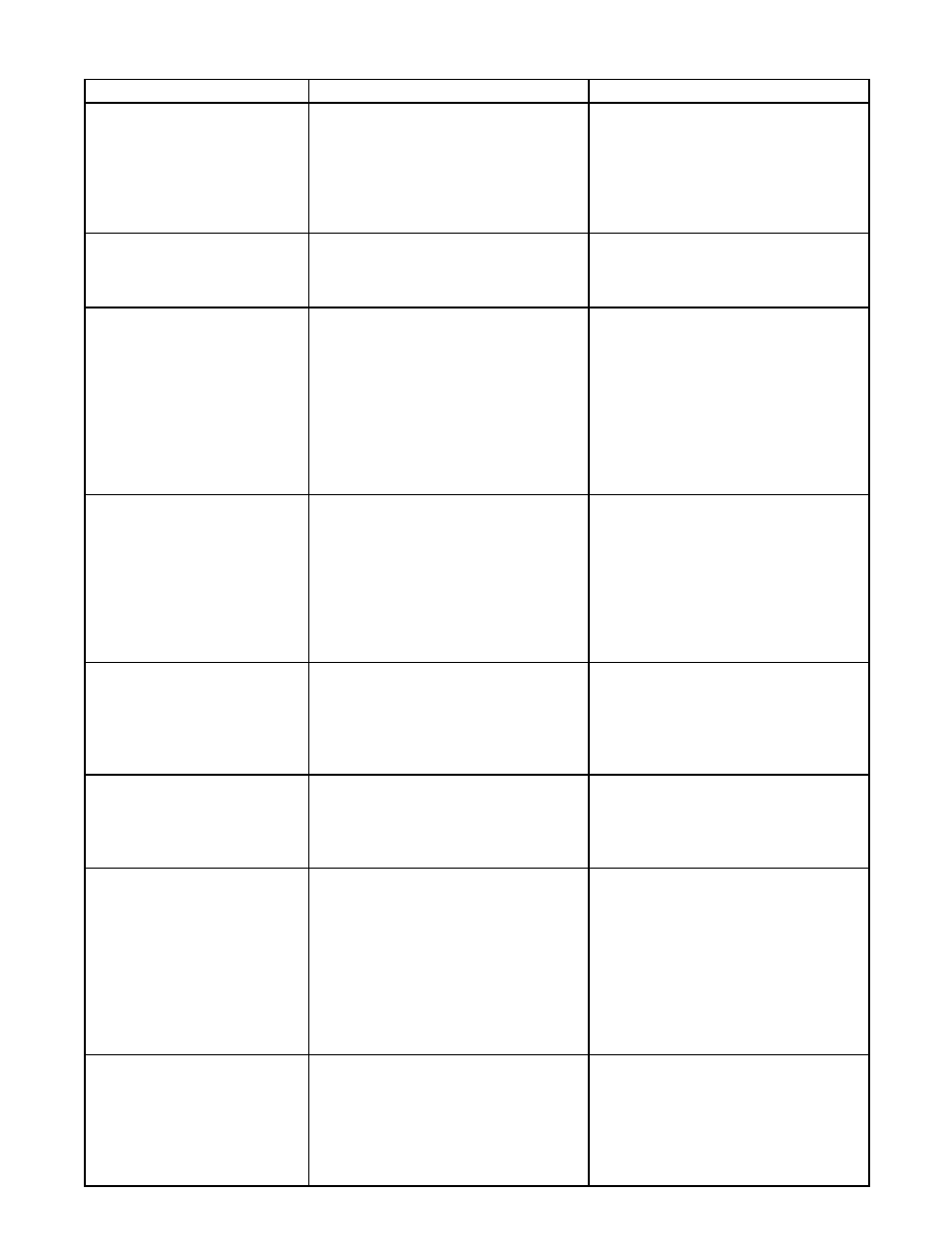

Troubleshooting guide, Table 8 – Sterling QVES User Manual

Page 25

25

Troubleshooting Guide

SYMPTOMS

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

Table 8

1. Reset manifold pressure. Refer to

"Operation".

2. Replace regulator section of combin-

ation gas valve or complete valve.

3. Check with local gas supplier for

proper orifi ce size and replace. Refer

to

"Operation".

1. Close air shutter. Refer to "Operation".

2. Check with local gas supplier for

proper orifi ce size and replace. Refer

to

"Operation".

1. Close air shutter.

2. Reduce pilot gas. Refer to "Operation".

3. Replace

orifi

ce.

4. Reset manifold pressure. Refer to

"Operation"; Replace regulator section

of combination gas valve or complete

valve; or Check with local gas supplier

for proper orifi ce size and replace.

Refer to "Operation".

1. Open air shutters. Refer to

"Operation".

2. Clean main burner ports.

3. Replace manifold assembly.

4. Clean draft hood.

5. Check for dust or lint at air mixer

opening and around the air shutter.

6. Clean combustion air inlet openings in

bottom panel, see "Installation".

1. Clean fl ue. Refer to "Installation".

2. Clean combustion air inlet openings in

bottom panel, see "Installation".

3. Clean heat exchanger.

4. Determine

cause and repair

accordingly.

1. Inspect all gas piping and repair.

2. Clean heat exchanger/fl ue.

3. Eliminate drafts. Refer to "Installation".

4. See

"Installation".

5. Clean draft hood.

1. Close air shutter. Refer to "Operation".

2. Clean main burner ports.

3. Reset manifold pressure. Refer to

"Operation".

4. Supply piping is inadequately sized.

Refer to "Installation".

5. Clean pilot orifi ce. Refer to

"Operation".

6. Eliminate drafts. Refer to "Installation".

7. Refer to "Installation".

1. Open all manual gas valves.

2. Replace fuse or turn on power supply.

3. Turn up thermostat

4. Check limit switch with continuity

tester. If open, replace limit switch.

5. Check wiring per diagrams.

1. Pressure regulator set too high.

2. Defective

Regulator.

3. Burner orifi ce too large.

1. Excessive primary air.

2. Burner orifi ce too small.

1. Too much primary air.

2. Noisy

pilot

3. Irregular orifi ce causing whistle or

resonance.

4. Excessive gas input.

1. Insuffi cient primary air.

2. Clogged main burner ports.

3. Misaligned

orifi

ces.

4. Clogged draft hood.

5. Air shutter linted.

6. Insuffi cient combustion air.

1. Blocked

venting.

2. Insuffi cient combustion air.

3. Blocked heat exchanger.

4. Air leak into combustion chamber or

draft

hood.

1. Shut off gas supply immediately!

2. Blocked heat exchanger/venting.

3. Drafts around heater.

4. Negative Pressure in building.

5. Blocked draft hood.

1. Excessive primary air.

2. Main burner ports clogged near pilot.

3. Pressure regulator set too low.

4. Pilot decreases in size when main

burners come on.

5. Pilot fl ame too small.

6. Drafts around heater.

7. Improper

venting.

1. Main gas off.

2. Lack of power at unit.

3. Thermostat not calling for heat.

4. Defective limit switch.

5. Improper thermostat or transformer

wiring at gas valve.

A. Flame lifting from burner

ports.

B. Flame pops back.

C. Noisy

fl

ame.

D. Yellow tip fl ame (some yellow

tipping on propane gas is

permissible).

E. Floating

fl

ame.

F. Gas

Odor.

G. Delayed ignition.

H. Failure to ignite.