Introduction, Specifications, 1 description – Yokogawa PR10 Retractable Assembly User Manual

Page 5: 2 features, 3 warranty, 1 general

5

IM 12B6K3-01E-E

1. INTRODUCTION

1.1 Description

The retractable fitting with ball valve allows

a safe insertion and retraction of a sensor

while the process is under pressure. It

can be mounted in a variety of positions.

The insertion depth can be selected on

site. An insertion stop is provided to set

the position of the sensor in the process.

The mechanism for releasing the probe

is designed to operate only when the ball

valve is closed, thus ensuring an effective

safety precaution and avoiding production

loss. The sensor can be replaced or

calibrated easily.

1.2 Features

• One model for pH, conductivity

and inductive conductivity sensors

• Integrated protection cage

• Build-in scraper to avoid contamination

of the fitting

• Usable for wide range of sensors

• A safe “through the valve” insertion

and retraction design

• Simplified installation by optional

ball valves with flanged or tapered

connections

• Optional flush port for keeping moist,

cleaning and calibration

• Available in Stainless Steel and with

Titanium shaft cage and adapters for

more harsh applications

1.3 Warranty

Yokogawa warrants that the goods

delivered are made from new materials to

the best workmanship available. Malfunction

of any of the delivered goods or parts of

it, can only lead to replacement of the

damaged parts. No claims can be made

to damages or accidents resulting from the

use of the goods. No claims can be made

to the expected or promised performance

of the goods under any circumstances.

Damaged goods or parts should be sent to

the local service organization for warranty

claim purposes. Yokogawa has the right to

deny warranty claims after investigation of

the data and materials.

2. SPECIFICATIONS

2.1 General

A. Wetted materials

- For sensor check Instruction Manual

- Stainless steel AISI 316L / Titanium

- O-ring seals: Viton 70° shore

B. Non-wetted materials

- For sensor check Instruction Manual

- Stainless steel AISI 316, 304

- Polypropylene glass filled

C. Insertion length

- Ref. mechanical drawing Fig. 2 - 5

on page 6 - 9.

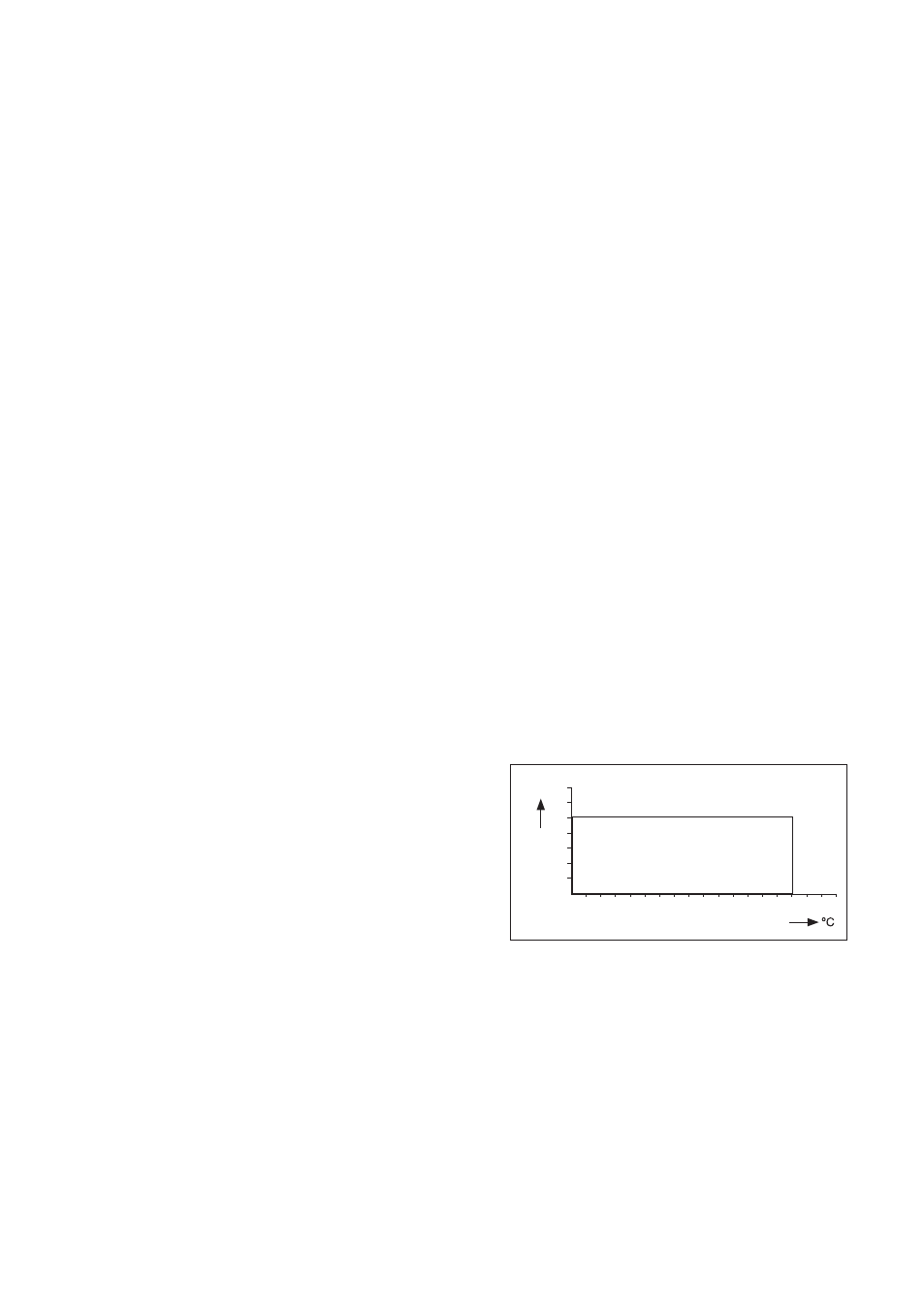

D. Pressure/temperature ratings

- Static conditions: see Fig. 1.

- Operating conditions during

extraction and insertion max.

500kPa, max. 100°C

E. Flange ratings:

- DIN flange DN32 PN10

- ANSI flange 1¼“ 150 lbs

- DIN flange DN50 PN10

- ANSI flange 2“ 150 lbs

F. Specifications of the sensor used

- Please check sensor specifications

G. Weight

- Approx 2.5 kg excl. ball valve

0 10 20 30 40 50 60 70 80

100

120

140

160

bar

2

4

6

8

10

12

AISI 316

FIG. 1 Pressure / Temperature graphic