Yokogawa EJX210B User Manual

Page 56

<8. Setting Parameters>

8-21

IM 01C27C01-01EN

b. To match current input and output value,

follow procedure

Like tank level measurement that is

impossible to set actual level to zero, output

value is adjustment to actual level by other

measurement using glass gauge.

This is an adjustment procedure example.

Conditions are as follows, measurement span

is 0 kPa to 25.00kPa, current level is 13.50kPa,

current output is 13.83kPa.

• Procedure to call up the lower limit

adjustment parameter (Calibration Lowest

Point).

AI1 block : Calibration Lowest Point

Set the actual level value of 13.50 kPa to the

Calibration Lowest Point parameter for the

differential pressure (AI1 block). Apply an

actual input and confirm the value specified

in Calibration Lowest Point as the output

value.

• Procedure to call up the calibration

adjustment parameter (Cal Cmd).

AI1 block : Cal Cmd : CAL_LOW

The present output is changed from 13.83

kPa to 13.50 kPa in CAL_LOW of the

differential pressure (AI1 block) Cal Cmd

parameter.

• Procedure to call up the calibration status

parameter (Cal Status).

AI1 block : Cal Status

Confirm the value of CAL_SUCCESS (1)

using the Cal Status parameter.

DPharp

F0806.ai

25.00 kPa

0.00 kPa

Actual level

13.50 kPa

DPharp span: 0~25.00 kPa

Actual level: 13.50 kPa

Transmitter output: 13.83 kPa

Figure 8.3

Tank level measurement

c. Using External Zero-adjustment Screw

External Zero-adjustment parameter (External

Zero Trim) can set permission or prohibition to

adjustment by External Zero-adjustment Screw.

Set “Trim on” to use the External Zero-

adjustment Screw. (“Trim on” at shipment)

Use a slotted screwdriver to turn the zero

adjustment screw. Turn the screw clockwise

to increase the output or counterclockwise to

decrease the output. The zero point adjustment

can be made with a resolution of 0.01% of the

setting range.

The degree of zero adjustments varies with

the screw turning speed; turn the screw slowly

to make a fine adjustment, quickly to make a

rough adjustment.

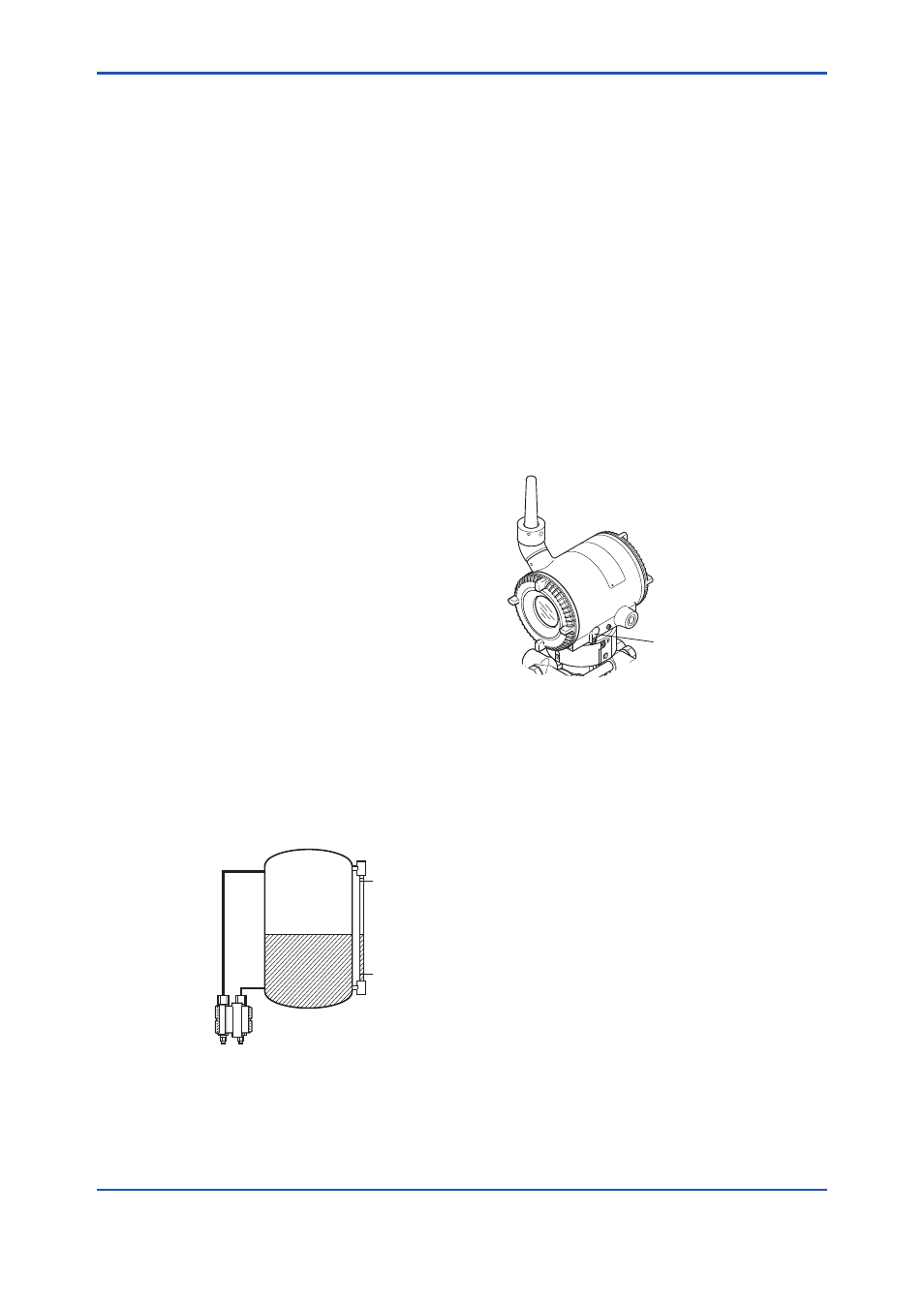

Zero-adjustment Screw

F0807.ai

Figure 8.4

Zero-adjustment Screw