Dimensions, Wiring guidelines, Installation – Watlow Series 145 User Manual

Page 2: User interface, Installation wiring guidelines

2

■

Watlow Series 145 User’s Manual

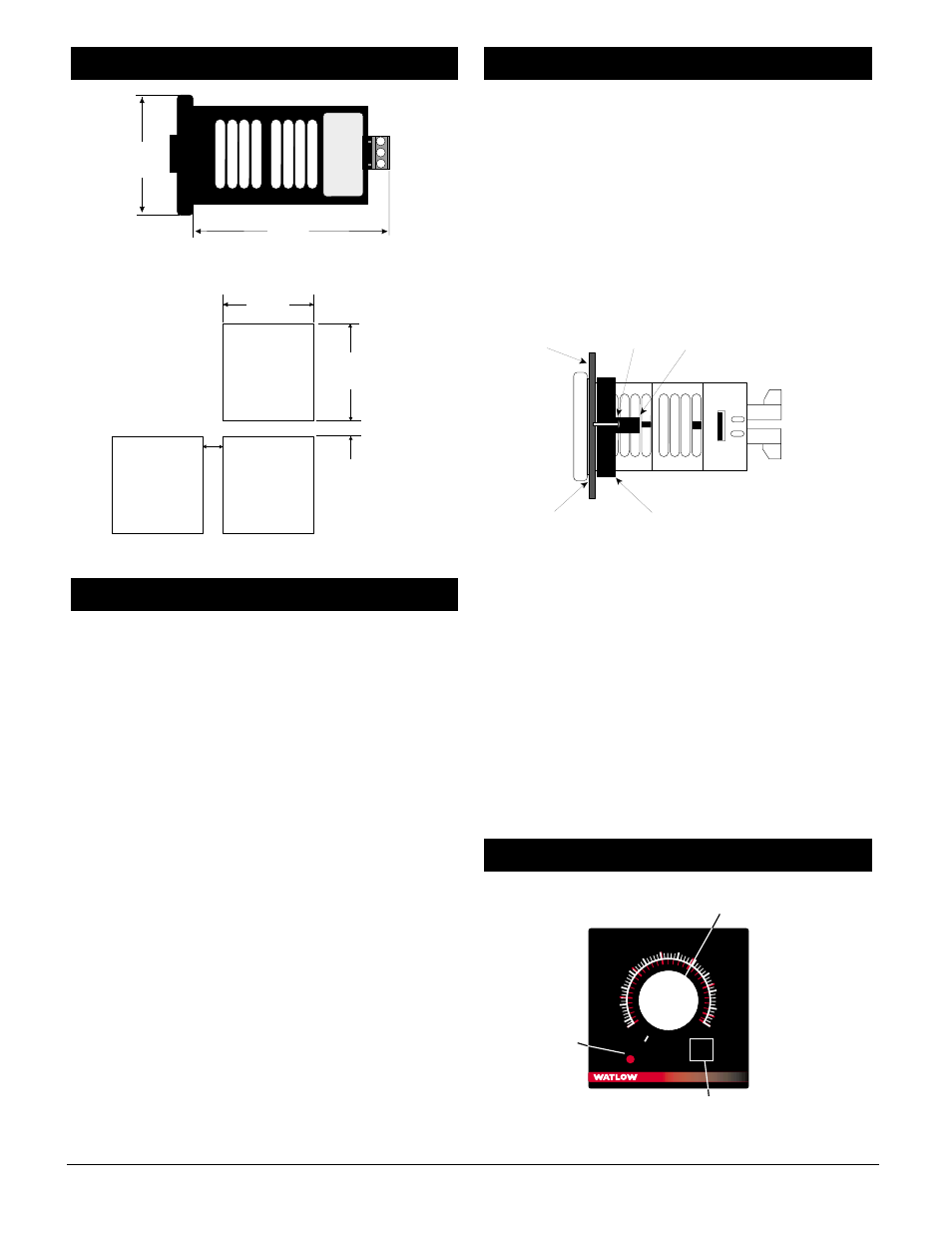

Figure 2a — Series 145 dimensions.

Figure 2b — Series 145 panel cutout.

• Use the correct sensor type per the model number on the

unit sticker.

• Use the proper thermocouple or RTD polarity.

• Insulate the thermocouple mounting from the mounting

surface to prevent heat migration input errors.

• Thermocouple leads should be twisted pair wire and

routed separately from any other lines.

• In electrically noisy environments (heavy switching of

contactor, motors, solenoids, etc.) use shielded thermocou-

ple lead wire with the shield connected at the sensor end

only.

• All wiring and fusing must conform to the National

Electric Code (NEC) NFPA70 and any other locally appli-

cable codes.

• Fuse the independent load voltage on the L1 (hot) side

and connect it to the common (COM) side of the relay.

ç

CAUTION: A power disconnect switch located near the controller

is recommended to shut down power in case of controller

failure.

• Long lead lengths create electrical resistance. When using

a two-wire RTD, there will be an additional error for

every 1

Ω

of lead length resistance. That resistance when

added to the resistance of the RTD element, can result in

erroneous input to the temperature controller. To over-

come this problem, use a three-wire RTD sensor, which

compensates for lead length resistance. When extension

wire is used for a three-wire RTD, all three extension

wires must have the same electrical resistance (i.e. same

gauge, copper stranded).

To Mount the Series 145

1. Make a panel cutout, using the dimensions in Figure 2b.

2. Check to see that the external case gasket of the Series

145 is facing the panel surface. Insure that the gasket is

not twisted and is seated within the case bezel flush with

the bezel. Insert the Series 145 into the cutout.

3. Slide the mounting collar over the back of the controller.

The two tabs of the mounting collar will fit into one of the

vent openings of the case.

4. While pressing the front of the case firmly against the

panel, tighten the two #8-32 screws until tight. Make sure

you cannot move the case within the cutout.

Figure 2c — Series 145 mounting.

NOTE: FM Approval requires limit switches to be suitably enclosed

to minimize casual readjustment of set temperature.

To Remove the Series 145

1. Remove the Series 145 by loosening the mounting screws

located on the mounting collar.

2. Using the screws, gently pry them away from the case.

This will lift the mounting tabs, allowing the collar to

slide backwards.

NOTE: To guarantee a proper seal, make sure the gasket between

the panel and the rim of the case is not twisted and is seated prop-

erly. Press firmly.

NOTE: Make sure the rounded side of the D-shaped external case

gasket faces the panel surface and the gasket is fully seated.

Figure 2d — Series 145 interface.

RESET

˚C

˚F

Alarm

145

100

150

200

250

300

350

400

450

500

550

600

50

0

50

150

200

100

250

300

315

Type J T/C

Alarm

Indicator

Temperature Adjustment

Setpot

Reset

User Interface

Panel

Screw

Mounting Tab

External Gasket

Mounting Collar

Installation

Wiring Guidelines

2.10"

1.75"

Panel Cutout

Your Panel

Thickness

0.06 to 0.38 in

(1.5 to 9.7 mm)

1.77 to 1.79 in

(45.0 to

45.5 mm)

1.77 to 1.79 in

(45.0 to

45.5 mm)

0.38 in

(9.7 mm)

Minimum

0.85 in

(20 mm)

2.1 in

(55 mm)

square

4.0 in

(102 mm)

Dimensions