PCT Engineered Converting Projects User Manual

Page 2

Project Objective: Upgrade Single-Layer Extruder to 7-Layer Extruder

Customer: Midwest Location of Major Blown Film Producer

PCT provided:

• Integrated system for control of the blending system,

vacuum pump, and extruder

• (7) multi-bay control enclosures including PLC,

drives, SSR’s and power distribution

• New operator stations

• Programming for the PLC, HMI, and drives

• Onsite commissioning and support

Project Objective: Supply of a Complete Electron Beam Process Line

Customer: South American Location of a Major Film Producer

PCT provided:

• Final design, fabrication, assembly and testing of turret

unwind, splicing station, chill roll stand and turret rewind

• Refurbishment, modification, assembly and testing of a

BroadBeam electron beam processor

• Integrated line control system including PLC’s, drives

and operator stations

• Shop testing of the entire line including training of

operators from the plant

• On site installation and commissioning support

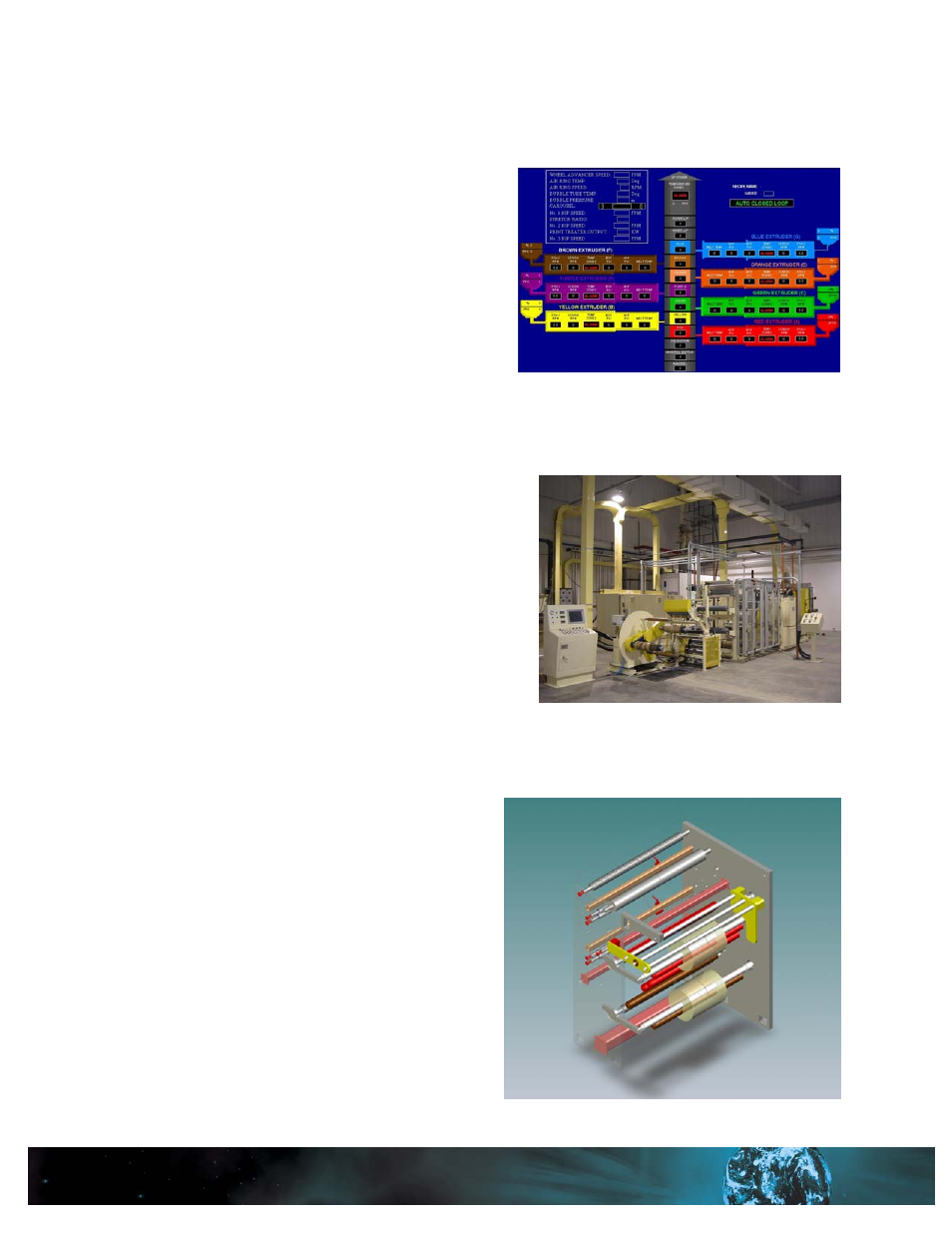

Project Objective: Modify Slitter Mechanics to Improve Reliability

Customer: Midwest Location of Major Blown Film Producer

PCT provided:

• Engineering study to recommend mechanical

changes

• Created a pass line drawing from customer

drawings

• Simplified the pass line by removing several rolls

and developed alternate thread paths for the

system

• Replaced 4 rolls in the unwind section based on

engineering discoveries

• Replaced 3, high inertia, “billy rolls” with a single,

low inertia roll

• Modified upper fold board roll for load cell mounts

to provide appropriate tension feedback

• Replaced the nip roll mechanisms with driven S-

wrap rolls

© 2007 PCT Engineered Systems LLC. All Rights Reserved