PCT Engineered EB-curing technology User Manual

Page 2

this product, and we were able to agree on what was needed, taking the order before the equipment was

released,” explains PCT sales and marketing manager Karl Swanson. The new model was formally

introduced in May, and Elopak is the first commercial installation of the BroadBeam LE.

Along with a smaller footprint, the LE uses a new power supply technology that they claim is 40-percent

more efficient than other EB units, and it operates at higher speeds than UV, Swanson says. The

BroadBeam also reportedly features lower taint, odor and substrate-heating temperatures. Applications

include web-offset and CI-flexo printing, laminating and specialty cross-linking.

Total in-line operation

At Elopak, in-line production is the rule. Carton substrate (typically poly-coated paperboard) is first

printed in seven colors and one clearcoat on a 7+1-station Komori Chambon (

www.komori-america.us

)

web-offset press, then EB-cured via the BroadBeam LE, and finally die-cut. The 120-ft-long line yields

carton blanks ready for finishing.

The Montreal plant's first run of EB-cured cartons came off the line

in July, and the operation achieved a top press speed of 1,150 fpm.

Mize describes the BroadBeam LE as “operator-friendly.”

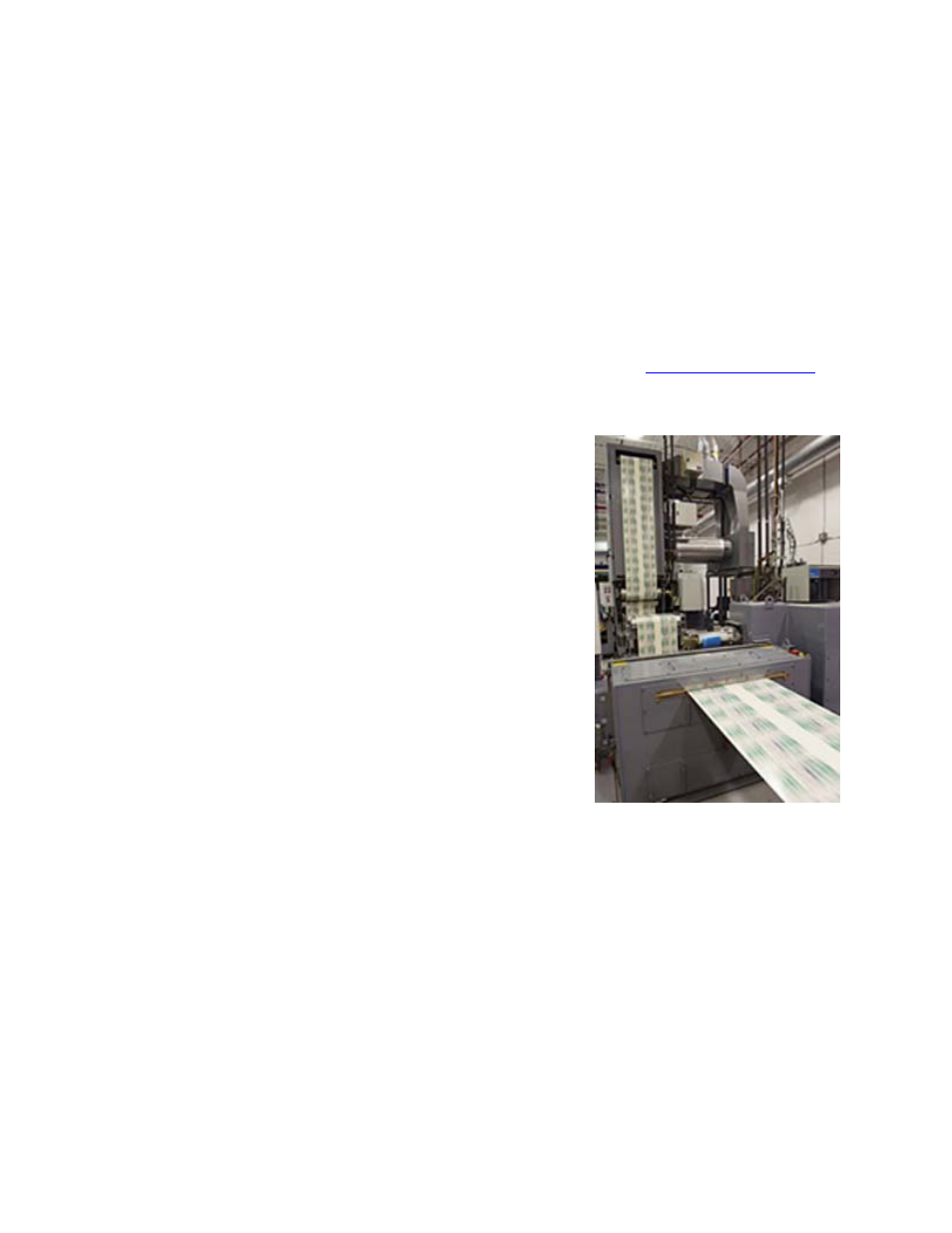

The printed paper web enters the PCT BroadBeam® LE Series

electron-beam curing system at Elopak Canada.

The line runs with five operators now, but plans are to reduce this to

four by adding automation to the delivery section. Mize describes the

EB-curing-equipped Komori Chambon as “the most technologically

advanced printing press in North America in our industry.”

He also has only good things to say about PCT's professionalism.

The supplier hosted the Elopak team for two days of operational and

maintenance classroom training at their site. “There's a lot of

technology, high-voltage electric, a vacuum system, nitrogen-inerting

supply—it's a new experience for operators,” Swanson explains.

“Our guys on the machine feel like Stealth bomber pilots,” Mize

says, “because they get to run the latest and greatest equipment. The successful startup is attributed to the

teams at PCT, Komori Chambon and the Elopak team, including project manager Aristoteles Noronha;

our top expert in North America on the Komori Chambon production manager Loren Arteberry; press

operators Daniel Auger and Francisco Costa; material-rolls shafter Claude Huneaulp and three takeoff

staffers Mathieu Alamy, Hyman Valentin and Jean Claude Baril.”

Mize is currently qualifying at least two of three prominent companies that provide Elopak with EB-

curing inks—Wikoff Color, Sun Chemical and Arets Graphics—during what has been designated as a

testing period.

And Elopak is already thinking of buying another carton printing/converting line. “We're modernizing to

state-of-the-art equipment,” says Mize, “and growing that way towards South America, and all through

Canada and the Caribbean.”