Wiegmann WPG Series User Manual

Page 2

K2

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

E N V I R O N M E N TA L C O N T R O L S

G E N E R A L I N F O R M AT I O N

Wiegmann has always recognized

that our customers in the electrical

and electronic marketplace need reli-

able, high quality enclosures and

environmental control products to

meet their protection requirements.

Protection Requirements today not

only mandate NEMA TYPE 12, 3R, 4,

& 4X, but also require a broad mix of

BTU & size selections. Wiegmann is

proud to offer those choices via a

whole new line of A/C products. They

are: Advantage Series, Trim Line

Series, Micro-Mini Series, Integrity

Series, and the Top Mount Series.

Three Basic Cooling Methods

When selecting a cooling method

there are three types to consider.

1 Passive Ventilation — If there is

only a minimal heat gain in your

circumstance, use of louvers or

grilles with filters can be effective.

This method, however, usually pro-

vides less cooling effect than is

necessary with today’s components.

2 Forced Convection Air Cooling —

If the installation will be in a clean,

non-hazardous environment with

an acceptable ambient (outside the

enclosure) temperature range, a

simple forced-air cooling system

utilizing outside air is usually ade-

quate. Combined with an air filter,

such devices generally meet the

heat removal needs of typical elec-

tronic equipment and many electri-

cal applications (Fig. 1). Examples

of forced convection air cooling are

filtered fans, fan trays, and blowers

of various types.

3 Closed-Loop Cooling — In harsh

environments involving high temper-

atures, wash-down requirements,

heavy particulate matter or the

presence of chemicals capable of

damaging components (NEMA 4 or

12 environments), ambient air must

be kept out of the enclosure. Closed-

loop cooling consists of two sepa-

rate circulation systems. One sys-

tem, sealed against the ambient air,

cools and recirculates the clean

cool air throughout the enclosure.

The second system uses ambient air

or water to remove and discharge

the heat. Examples of closed-loop

cooling equipment employed with

electronics and process controls

are heat exchangers and air

conditioners.

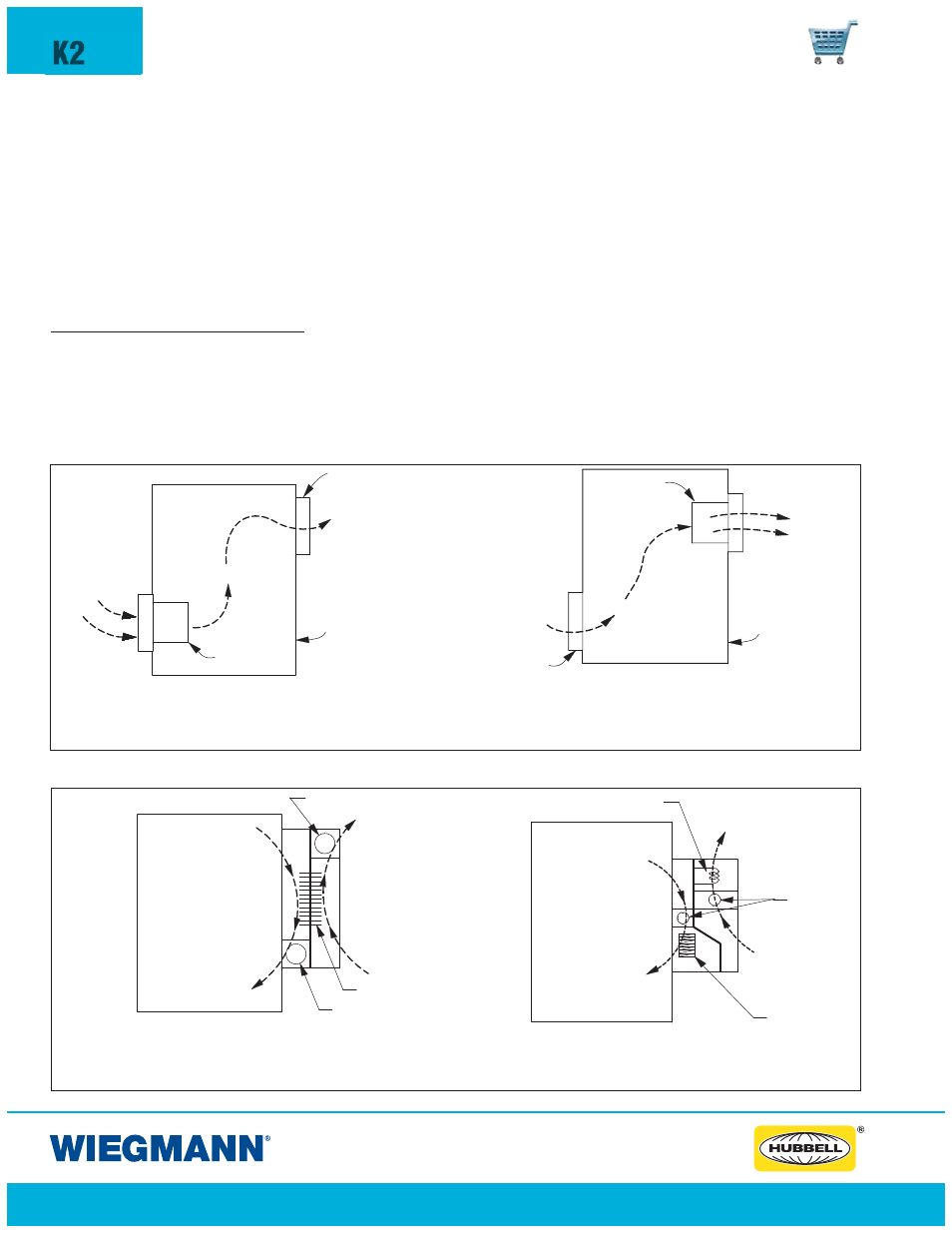

FIGURE 1 — Forced Convection Method

FIGURE 2 - Closed Loop Cooling Method

Fans and Blowers can be used to pressurize (preferred) or exhaust cabinet air.

The ambient air should be filtered before it enters the cabinet.

Pressurized System — pushes air through enclosure

In an air-to-air heat exchanger, heat from air surrounding the

electronics is removed by a specially designed heat transfer

element before being routed back into the enclosure.

Filter & Grille

Required

Ambient Air

with Heat

Load

Ambient

Air

Fan or

Blower with

filter & grille

Cabinet

Fan or Blower

with filter &

grille

Cabinet

Ambient Air

Ambient

Air with

Heat Load

Filter & Grille

Required

Blower

Ambient Air

with Heat

Load

Heat Exchanger

Ambient Air

Blower

Cooled Air

Heated

Air

Exhaust System — pulls air through enclosure

Ambient Air

with Heat

Load

Ambient Air

Heated

Air

Condenser

Blowers

Evaporator

Chilled

Air

In air conditioners, a condenser, an evaporator, and two blow-

ers combine to chill the air circulating in the enclosure.

- WPFM Series WPFG Series WPFA Series WPF Series FILTER MATS Series EXHAUST FILTER Series FILTER FANS Series WAFMP Series ETF Series ZR Series ETR Series EGL Series WCR Series WHVL Series EHG Series WAFLT Series WAVK-SS Series WAVK Series WAGARD Series WAAXFN Series WPFBE Series WPFB Series Vortex Coolers Series Top-Mount Series 47 Series 38 Series 32 Series MM Series NP47 Series NP36 Series NP33 Series NP28 Series NP17 Series RP47 Series RP36 Series RP33 Series RP28 Series RP17 Series