With trapped pressure relief – Ross Controls 2_2 WAY WITH PRESSURE RELEASE SERIES 27 User Manual

Page 3

4

© 2009, ROSS CONTROLS

®

.

All Rights Reserved.

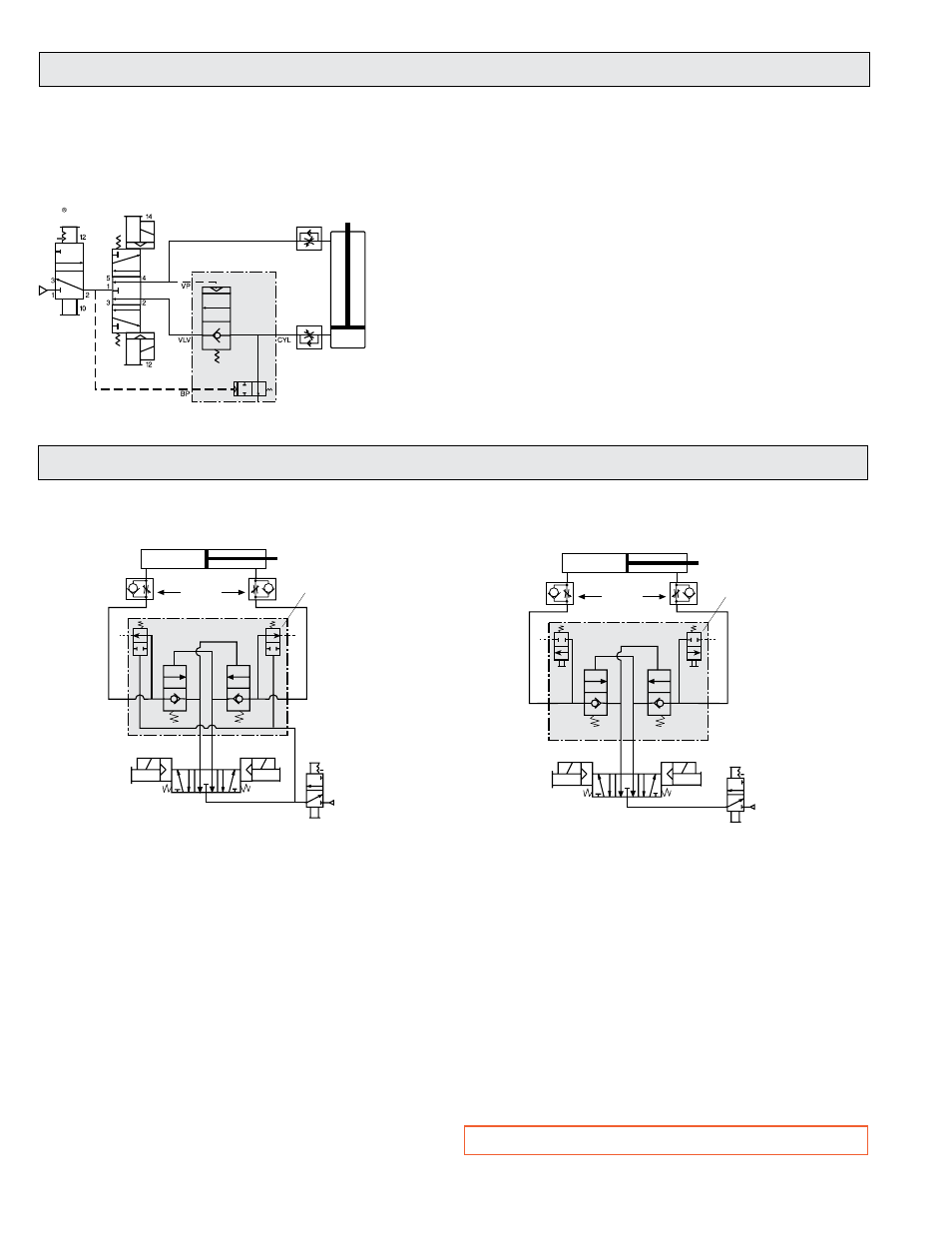

Dual Internal Pressure Controlled PO Check Valve Applications

Remote Trapped Pressure Relief

Manual Trapped Pressure Relief

V1

V2

3-Position, Open-

Center Control Valve

Cylinder

L-O-X®

Valve

Flow

Control

Valves

Dual Check

Valve with

Internal Pilot

C1

C2

B

A

Manual-controlled

Check Valve relief

V1

V2

3-Position, Open-

Center Control Valve

Cylinder

L-O-X®

Valve

P

Holding

Pressure

Flow

Control

Valves

Dual Check

Valve with

Internal Pilot

C1

C2

Remote-controlled

Check Valve relief

CIRCUIT FEATURES:

• Trapped pressure between check valve and cylinder is exhausted

when the air supply at “P” port is lost or locked-out.

• Cylinder moves as long as a control valve solenoid is energized.

Use for continuous motion or jogging.

• Cylinder remains stationary if neither control valve solenoid is

energized, or if electrical signal is lost.

• L-O-X

®

valve provides lockable shutoff of air supply, and

exhausting of trapped downstream air.

IMPORTANT NOTES and CAUTIONS:

» Cylinder movement may occur when inlet pressure is lost. Its

movement is slowed only by the restrictions of the flow control

valves, and by the exhaust capacity of the check valve relief flow

capacity.

» For best response, flow control valves should be installed

between the check valve and the cylinder.

» Pressurizing the system after supply air has been off may

cause rapid movement of the cylinder because cylinder air

was exhausted while the supply air was off. See page 5 for

soft-startup circuit.

CIRCUIT FEATURES:

• Trapped pressure between check valve and cylinder is

exhausted when pushbuttons A and B are pressed.

• Cylinder moves as long as a control valve solenoid is energized.

Use for continuous motion or jogging.

• Cylinder remains stationary if neither control valve solenoid is

energized, or if electrical signal is lost.

• L-O-X

®

valve provides lockable shutoff of air supply.

IMPORTANT NOTES and CAUTIONS:

» Cylinder movement may occur if only one pushbutton (A or B)

is pressed. To exhaust fully both cylinder ports, push and hold

A and B simultaneously.

» For best response, flow control valves should be installed

between the check valve and the cylinder.

» Pressurizing the system after supply air has been off may

cause rapid movement of the cylinder. See page 5 for soft-

startup circuit.

L-O-X (Lockout

& eXhaust Valve)

3-Position, Open-

Center Control Valve

Single PO Check Valve

Vertical

Cylinder

Single Pressure Controlled PO Check Valve Application

CIRCUIT FEATURES:

• Trapped pressure between check valve and cylinder is exhausted when the

air supply at the Blowdown Signal Port (BP) is lost or locked-out.

• Cylinder moves as long as the control valve solenoid is energized. Use for

continuous motion or jogging.

• Cylinder remains stationary if neither control valve solenoid is energized, or

if electrical signal is lost.

• The single PO check with pressure relief have an additional 1/8” NPT port

provided for the installation of a pressure sensing device such as a pop-up

indicator or pressure switch. Standards suggest that machine design should

include a method for verifying the release of stored energy.

IMPORTANT NOTES and CAUTIONS:

» Cylinder movement may occur when inlet pressure is lost. The cylinder’s

movement is slowed only by the restrictions of the flow control valves, and

by the exhaust capacity of the check valve relief flow capacity.

» For best response, flow control valves should be installed between the check

valve and the cylinder.

» Pressurizing the system after supply air has been off may cause rapid movement

of the cylinder because cylinder air was exhausted while the supply air was off.

With Trapped Pressure Relief

TYPICAL APPLICATIONS:

Horizontal or vertical long-stroke cylinders.

NOTE: See Installation and Troubleshooting on page 6.

TYPICAL APPLICATIONS: Horizontal or vertical long-stroke cylinders.