Ross Controls LOW TEMPERATURE SERIES 21 User Manual

Page 3

10

© 2009, ROSS CONTROLS

®

.

All Rights Reserved.

Vacuum service valves are ideal for lifting, holding, vacuum

packaging and moving anything from large objects to tiny

particles. They also provide Vacuum service valves are ideal

for lifting, holding, vacuum packaging and moving anything from

large objects to tiny particles. They also provide an effective

means for leak testing. The vacuum source typically comes

from either a vacuum pump or a venturi. In vacuum service

applications, the pressure within the valve is reduced below

atmospheric pressure. Consequently, atmospheric pressure

actually pushes air into the valve, instead of the common belief

that air is “sucked” in by the vacuum.

In normal valves, filters exist to clean compressed air, which is

then pushed through the valve. In vacuum valves, there is no

filter, and the air comes from the atmosphere and enters through

the outlet, bringing with it atmospheric and nearby surface dust

and dirt. Vacuum valves, in order to function consistently, must

therefore be highly tolerant of the particles that freely flow into

the valves.

To construct a vacuum service valve system, typically a 3/2

normally closed valve is used. The vacuum is on the inlet, while

the exhaust remains open to atmosphere. Port 2 is the working

port. However, if there is a need for the vacuum service valve to

function as normally open, simply connect the vacuum source to

the exhaust and port 1 to atmosphere. Several variations of this

construction are effective, including using 2/2 valves.

“Full Vacuum” Valves

Though there are fewer applications for full vacuum valves

than regular vacuum valves, full vacuum valves are ideal for

applications where compressed air is unavailable. Full vacuum

valves use the difference in force between atmospheric pressure

and the vacuum within the valve to actuate the valve. The full

vacuum valve performs with atmospheric pressure in port 1 and

10 to 30 inches of Mercury vacuum in the valve body.

Remote Air or Solenoid-Piloted Vacuum Valves

Pilot vacuum valves provide a greater variety of applications,

operating with a combination of vacuum and atmospheric

pressure. The pilot must be supplied externally with a minimum

of 30 psig. Vacuum valves can be used as either 3/2 normally

closed or normally open valves, with vacuum supplied at either

port 1 or port 3. Normally closed and normally open 2/2 versions

are also available.

What are Vacuum Service Valves?

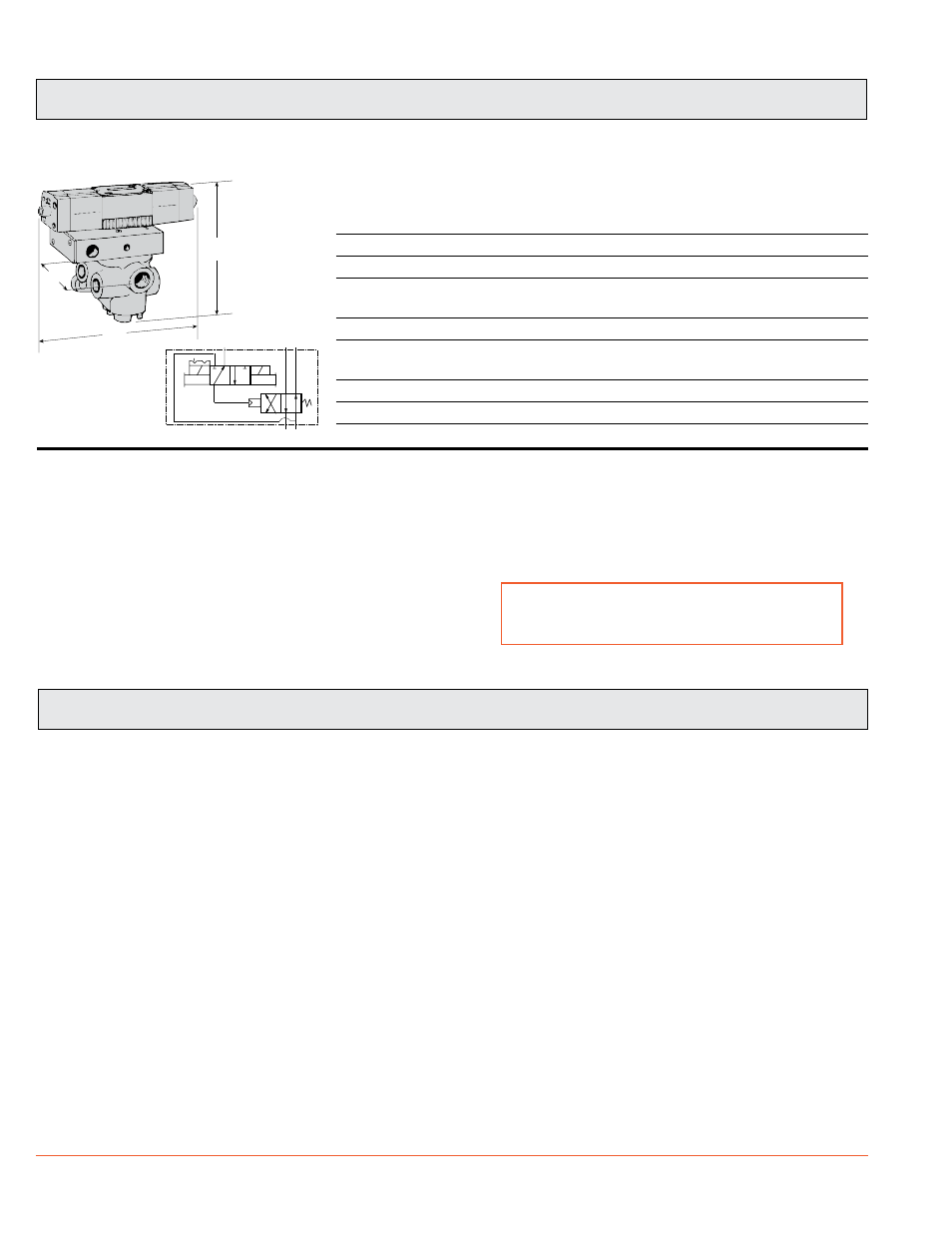

Series 21 Poppet Valves for Line Mounting

4/2 Valves – Double Direct Solenoid Controlled, Detented

1

2

3

4

Y

12

14

A

B

C

Port Sizes Valve Model Avg.

Dimensions inches (mm)

Weight

In-Out Exh.

Number

C

V

A

B

C

lb (kg)

1/4 1/2

2176C2003 2.5

8.9 (226)

3.9 (97)

6.9 (176)

4.0 (1.8)

3/8 1/2

2176C3003 3.6

8.9 (226)

3.9 (97)

6.9 (176)

4.0 (1.8)

1/2 1/2

2176C4013 3.7 8.9 (226)

3.9 (97)

6.9 (176)

4.0 (1.8)

1/2 1

2176C4003 6.9

8.9 (226)

5.2 (132)

8.7 (221)

6.5 (3.0)

3/4 1

2176C5003 8.2

8.9 (226)

5.2 (132)

8.7 (221)

6.5 (3.0)

1

1

2176C6013 8.9

8.9 (226)

5.2 (132)

8.7 (221)

6.5 (3.0)

1

11/2

2176C6003

23

8.9 (226)

8.2 (208)

10.4 (265) 13.3 (6.0)

11/4 11/2

2176C7003

24

8.9 (226)

8.2 (208)

10.4 (265) 13.3 (6.0)

11/2 11/2

2176C8013

25

8.9 (226)

8.2 (208)

10.4 (265) 13.3 (6.0)

STANDARD SPECIFICATIONS: For valves listed above.

Solenoids: AC or DC power.

Standard Voltages: C

onsult ROSS.

Power Consumption: Each solenoid; 190 VA inrush, 40 VA

holding on 50 or 60 Hz; 20 watts on DC.

Indicator Lights: In each solenoid housing.

Ambient Temperature: 40° to 120°F (4° to 50°C).

Media Temperature: 40° to 175°F (4° to 80°C).

For temperatures below 40°F (4°C) air must be free of water

vapor to prevent formation of ice.

Flow Media: Filtered air; 5 micron recommended.

Inlet Pressure: 30 to 150 psig (2 to 10 bar).

Pilot Pressure: If external supply is used, pressure must

be equal to or greater than inlet pressure.

Threads: Model numbers above specify NPT pressure port

threads. For other threads, consult ROSS.

IMPORTANT NOTE

Please read carefully and thoroughly

all of the

CAUTIONS on the inside back cover.