How it works, Warranty and cautions – Ross Controls 5599_I ENERGYSAVER SERIES W60 User Manual

Page 2

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

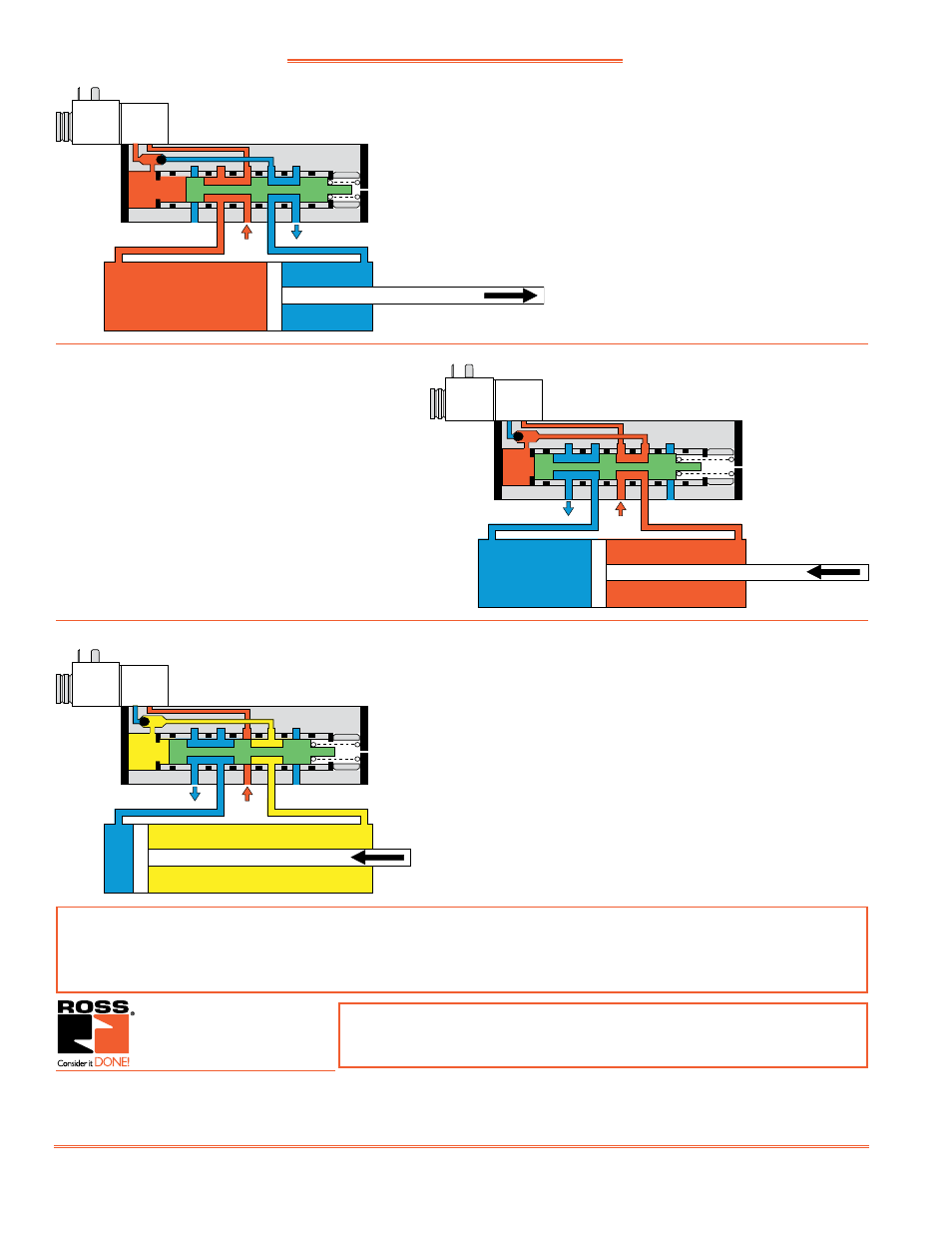

How It Works

Solenoid Energized

Solenoid De-energized

Energy Saving Mode

(Solenoid de-energized)

NOTE: The example of “How it Works” is specific to the single

solenoid E

NERGY

S

AVER

®

valve. The double solenoid models

operate similarly, but as a double solenoid type valve. If you

have specific questions about the operation of the double or

single solenoid E

NERGY

S

AVER

®

valves, please contact ROSS (see

contact information below) for more information.

When the solenoid is energized, the E

NERGY

S

AVER

®

valve operates

as a standard valve. Supply pressure is directed from the inlet

port to port 4 extending the cylinder at full pressure and force.

Air in the rod end of the cylinder is exhausted via port 3.

Upon de-energizing the solenoid, the pilot valve starts

to exhaust the pilot signal from the end of the spool.

Momentarily, the spool shifts back to a “normal” de-

energized position directing inlet air to flow to the rod end

of the cylinder (port 2 of the valve) and exhausting the

cap end.

The shuttle now has higher pressure on the opposite side

causing it to shift. Shifting the shuttle closes the connection

from the spool to the pilot exhaust and opens the cavity at

the end of the spool to feedback pressure from port 2.

Meanwhile the cylinder has begun to retract.

Because the actuating end of the spool now has high pressure

applied, the spool starts to shift to the right again closing off the

inlet port. Closing the inlet prohibits the air supply from maintaining

pressure on the rod end of the cylinder and as the cylinder continues

to retract, the pressure drops.

This pressure drop reduces the amount of force available to keep

the spool actuated against the valve return spring. So, the spool

starts to shift back thus allowing an influx of pressure to help retract

the cylinder.

The E

NERGY

S

AVER

®

valve operates as a fixed spring regulator when in

the energy saving mode, maintaining the cylinder return pressure at

approximately 30 psig (2 bar). Retracting and holding the cylinder

with only 2 bar pressure consumes much less air than the standard

method of using full pressure to shift and retract.

APPLICATION WARNING: When inlet pressure is 45 psig (3 bar) or less, the double and single solenoid E

NERGY

S

AVER

®

valves

will pressurize port 2 and exhaust port 4, regardless of applied solenoid signals. This feature, which occurs when inlet pressure

is below 45 psig (3 bar), must be taken into consideration in your application design in order to avoid the potential for personal

injury or property damage.

Printed in the U.S.A. – Rev. 06/09

©

2003, 2009

ROSS CONTROLS

®

. All Rights Reserved.

Form NPS257

WARRANTY and CAUTIONS

Standard ROSS warranty and cautions apply, available upon request or at

www.rosscontrols.com

ROSS EUROPA GmbH

Germany

Fax: 49-6103-74694

ROSS ASIA

®

K.K.

Japan

Fax: 81-427-78-7256

ROSS UK Ltd.

United Kingdom

Fax: 44-121-559-5309

ROSS SOUTH AMERICA Ltda.

Brazil

Fax: 55-11-4335-3888

ROSS CONTROLS

®

INDIA Pvt. Ltd.

India

Fax: 91-44-2625-8730

DIMAFLUID s.a.s.

France

Fax: 33-01-4945-6530

ROSS CONTROLS

(CHINA) Ltd.

China

Fax: 86-21-6915-7960

ROSS CONTROLS

®

U.S.A.

Customer Svs. 1-800-GET-ROSS

Technical Svs. 1-888-TEK-ROSS

www.rosscontrols.com