Airvantage sensor servicing – Versa-Matic 2 Clamped Metallic Ball Valve Pumps (RE2) User Manual

Page 19

re2mdlAsmC-rev0314

www

.

versamatic

.

com

3: EXP

VIEW

Model RE2 Metallic Clamped •

16

airVantage Sensor Servicing

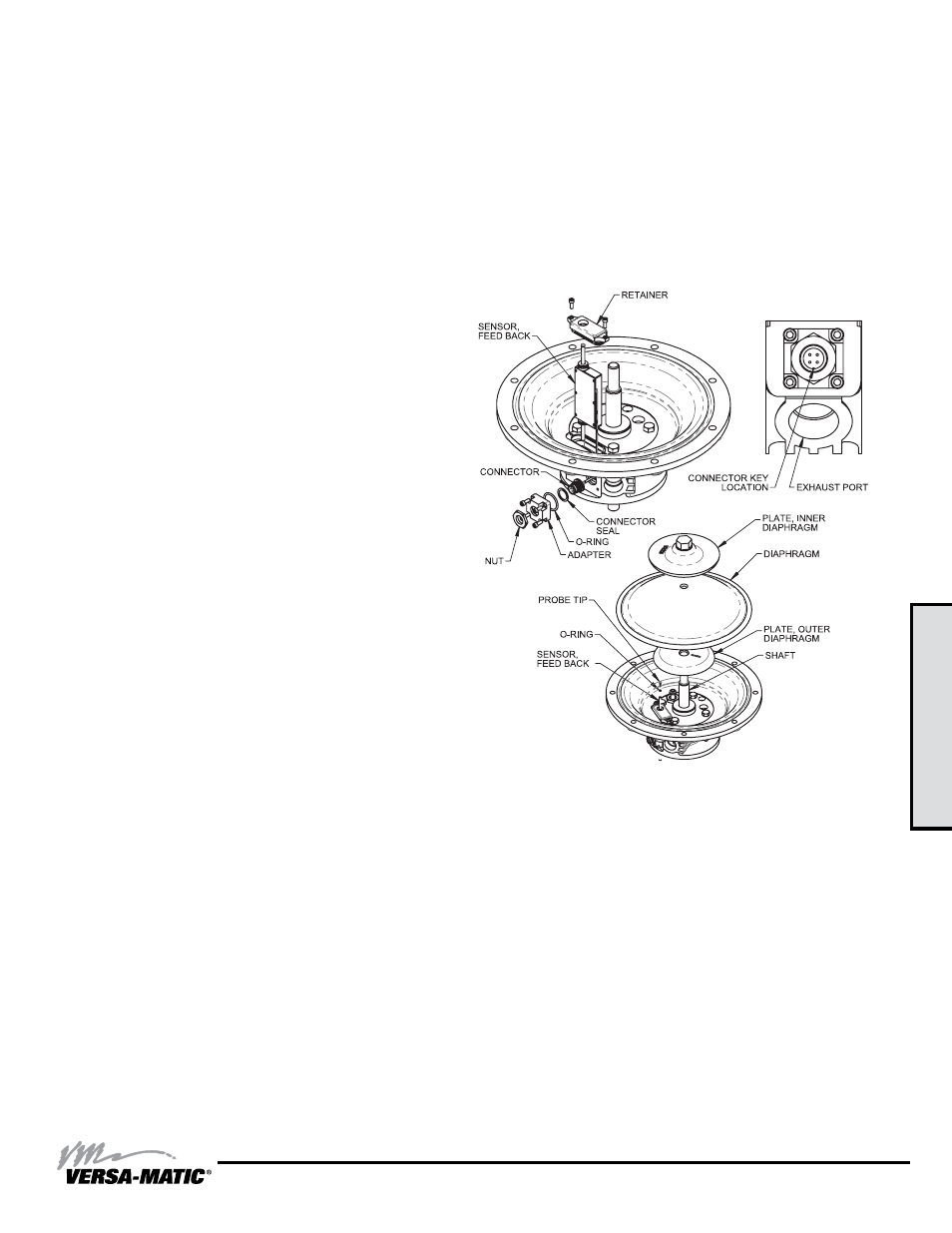

INTERMEDIATE AND AirVantage SENSOR SERVICING

To service the intermediate and AirVantage sensor, first shut

off and bleed the air being supplied to the pump. For safety

purposes, the air supply line should be disconnected from

the pump. Shut off both the suction and discharge lines to the

pump. Consult the “Composite Repair Parts Drawing”.

Step #1: Remove the Patch Cable

Twist the ribbed portion of the patch cable connector in

a counterclockwise direction, until it unthreads from the

connector. The cable can either be removed from the

intermediate or from the control module.

Step #2: Remove the AirVantage from the Pump

Use a ½” socket and remove the four 5/16-18 x 5 1/2 cap

screws that hold the AirVantage to the pump. Remove the two

bolts that are holding the right side bracket to be able to remove

the right bracket and AirVantage unit from the pump. Be sure

to support the weight of the AirVantage while removing the last

cap screw. After the AirVantage is removed from the pump, set

the unit down on the plastic cover located on the bottom.

Step #3: Remove the Manifolds, Chambers, and

Diaphragms (Refer to exploded views for disassembly)

Step #4: Remove the Diaphragm Assemblies

Refer to exploded views for disassembly.

“AirVantage CAUTION” – When the diaphragm assembly

is removed, watch for the brass probe tips located on the

end of the sensor rod. There is one brass probe tip and

one o-ring per side. Inspect the probe tips and o-rings for

wear. For every diaphragm service, these parts should

be replaced and are available in kit form. Consult the

“Composite Repair Parts Drawing” for part numbers and

quantities.

Step #5: Accessing the AirVantage Sensor

Use a 9/64" hex key wrench to remove the 4 socket head cap

screws from the sensor connector plate. Use a 13/16" socket

and remove the plastic nut securing the connector to the

connector plate. Remove the connector from the connector

plate taking care not to lose/misplace the gasket on the

connector or the o-ring that seals the connector plate. Next,

use a 9/64" hex key wrench to remove the 2 socket head cap

screws on each sensor end cap. Use a small flat screwdriver

to gently pry the end caps from the inner chambers. Now slide

the sensor out of the intermediate while feeding the connector

and cable into the intermediate. Slide the Connector end of

the cable out of the same opening as the sensor.

Step #6: Reinstallation

Note that the orientation of the sensor rod with respect to the

pilot shaft location. The sensor rod side of the sensor should

be on the "top" side of the pump (facing the air valve side of

the pump). Slide the Connector end of the cable and then

the sensor into the sensor opening. Feed the connector out

through the opening in the intermediate. Ensure the gasket

is on the connector and the connector plate o-ring is in the

connector plate o-ring groove. Insert the connector into the

connector plate. Use a 13/16" socket to install the plastic nut

in order to secure the connector to the connector plate. Use a

9/64" hex key wrench to install the 4 socket head cap screws

and secure the sensor connector plate to the intermediate.

Install the sensor end caps. Be sure not to pinch or cut the

sensor o-rings. Use a small amount of lubrication if necessary

to ease assembly. Use a 9/64" hex key wrench to install the 2

socket head cap screws on each sensor end cap to secure the

sensor.