Hose reel operations manual – Reelcraft Nordic Series 2000 Reels User Manual

Page 3

Hose Reel Operations Manual

www.reelcraft.com

Page 3

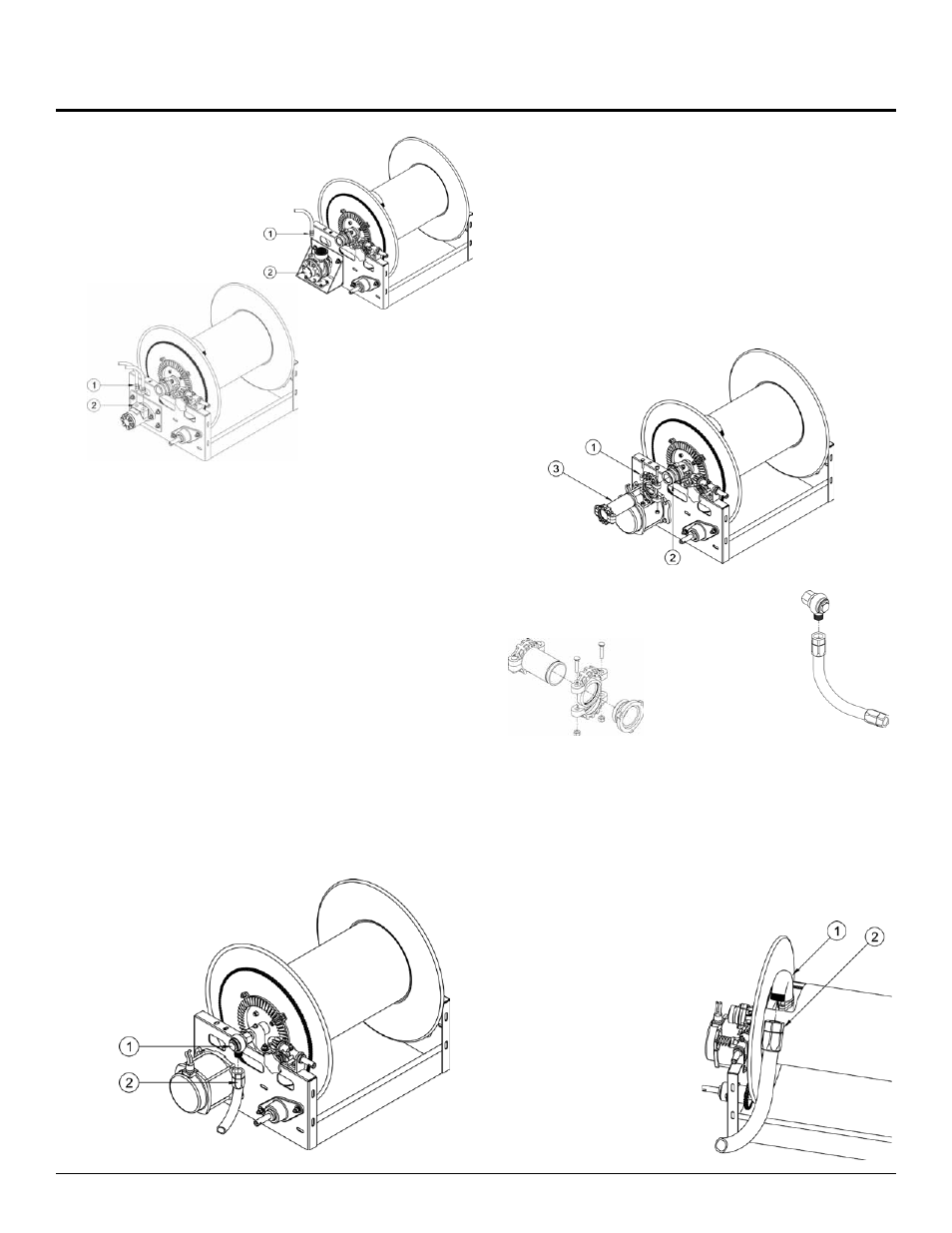

AIR DRIVEN REELS

1. Apply thread compound to

inlet air line fitting (1) and

pneumatic motor (2) inlet

threads.

2. Connect inlet air line

(1) to motor (2).

HYDRAULIC DRIVEN REELS

1. Apply thread compound inlet / outlet hydraulic line fittings

(1) and hydraulic motor inlet threads (2).

2. Thread hydraulic line fittings (1) into motor inlet / outlet (2)

tighten securely.

INLET CONNECTION

NOTE: Install a union fitting as near as possible to the swivel

joint inlet, so the joint can be easily removed for servicing.

CONNECTING THE SUPPLY LINE FOR THREADED INLET

SWIVELS

NOTE: Avoid strain on swing joint at all times. Threaded type

swivel inlets must be connected to the fluid supply by using a

flexible connector.

1. Apply thread compound to the swivel (1) and connecting

hose fitting (2) threads.

2. Thread connecting hose fitting (2) into swivel (1). Tighten

securely.

3. With control valve open, fully extend and charge hose

to purge system of gases. When fluid appears at control

valve, close valve. This prevents flattening of hose and ex-

cessive pressure on drum when fluid supply is reinitialized

at a later time.

VICTAULIC INLET SWIVELS

NOTE: Victaulic - Type swivel joint inlet connections must be

carefully aligned. Two victaulic connections, correctly installed,

allow adequate flexibility for smooth rotation.

1. Connect victaulic coupling onto inlet swivel fitting and inlet

supply line

2. Adjust inlet supply line to verify flexibility exists for proper

alignment.

3. With control valve open, fully extend and charge hose

to purge system of gases. When fluid appears at control

valve, close valve. This prevents flattening of hose and ex-

cessive presure on drum when fluid supply is reinitialized

at a later time.

VICTAULIC

CONNECTION

FLEXIBLE

CONNECTION

NOTE: Failure to

use flexible con-

nector with any

live reel will void

warranty

For larger reels, gooseneck may be removed from reel to fit to

hose. Note that if the reel has a welded or threaded riser in the

fluid path assembly, it cannot be removed to attach the hose.

CAUTION: Do not connect the output hose to the gooseneck

(1) until after the reel is installed and motor connections are

complete. Fill the hose before winding on the reel to prevent

excessive pressure on the drum when hose is filled.

1. Apply thread compound

to connecting gooseneck

(1) and output hose fitting

threads (2).

2. Hand thread output hose

fi tting (2) into gooseneck

(1).

3. Using a wrench, fi rmly

hold gooseneck (1) while

tightening out put hose fit-

ting (2).