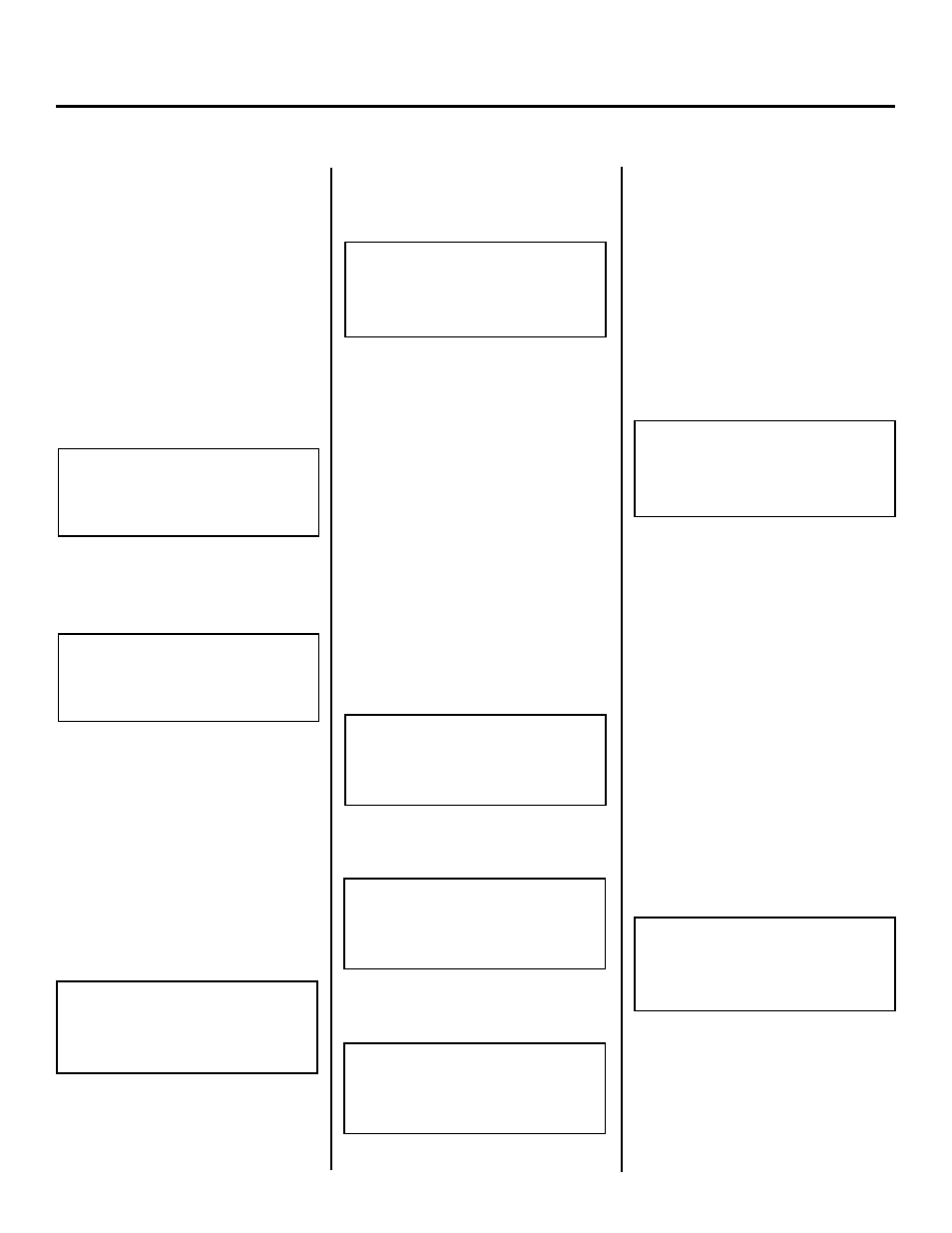

Programming procedure – Rapid-Air SERVO FEED / RAPID MASTER User Manual

Page 9

The intent of this section is to

familiarize the operator with the

program flow and what to expect

with every keypress. Each screen

on the display will be reviewed with

special comments to help clarify

what is being asked on the screen.

The program flow is broken down

into 5 sections with the main menu

being the home position.

The first screen to be displayed on the

operator terminal will look like this

. RAPID-AIR.CORPORATION

. 4601.KISHWAUKEE.STREET

. ROCKFORD,.IL.61109

. 815-397-2578

After a few seconds, the display will

clear and the following display will

appear:

. MAIN.SELECTION.MENU

. F1=JOB.NUM..F2=MANUAL

. F3=AUTOMATIC.CYCLE

. F4=REVIEW.PARAMETERS

SELECT.F1=JOB.#

The first step in programming the

servo feed is to select a job number

which will be used to store the

parameters the operator inputs or

recall the parameters which have

been previously loaded into the

servo controller program. When the

operator selects F1 on the keypad,

the screen will change to:

. JOB.#.SELECTION.MENU

. ENTER.IN.NEW.JOB.#=XX

. PRESS.F4.KEY.AFTER

. CORRECT.#.IS.ENTERED

The operator must enter a 2-digit

number before proceeding to any

other function. If the job number the

operator has entered has been

previously stored in memory, or

entering a new job, the following

display will appear:

. JOB.NUMBER-01.LOADED

. F1=PROGRAM.PARAMETERS

. F4=DON’T.ALTER.VALUES

. THAT.ARE.PROGRAMMED!

If entering in a new job then select

(F1) “program parameters” and follow

the directions.

The job number screen displays (2)

choices for the operator. In the first

choice, F1=Program new values, the

operator can enter or change the,

pilots, feed length, % of max speed

and cut time. This then calculates the

optimum speed of the material

movement. The second choice,

F4= Don’t alter values that are

programmed, puts the job number

entered in memory for running at this

time. If F1 was selected the following

display would appear.

. FEED.ADVISOR.JOB#=00

. FEED.LENGTH=000.000

. CUT.=.XXX.%.RATE=100

. F4=EXIT.FEED.ADVISOR

This window is displayed during job

setup calculations.

. CALCULATING.THE.FEED

. SPEED,.ACCEL.VALUES

. PLEASE.WAIT.FOR.MAIN

. MENU.TO.BE.DISPLAYED

Pressing the F4 key at any time

returns you to the main menu.

. MAIN.SELECTION.MENU

. F1=JOB.#.F2=MANUAL

. F3=AUTOMATIC.CYCLE

. F4=REVIEW.JOB.PROGRAM

programming procedure

Operator.Input.Terminal.–.Programming.Procedure.–.Standard.Software

In order to advance material into the

die, using the servo feed, the operator

has to be in the manual mode.

Pressing the F2 on the keypad will

cause the screen to change to the

manual mode screen. (Cycle rolls

with keys) - If the keypad has keys

with open rolls or closed rolls on it

then the keys are active at this time

and the rolls can be electrically

released for inserting the material into

the servo feed.

. MANUAL.MODE.F1=INCH

. F2=SINGLE.FEED.MODE

. F4=EXIT.MANUAL.MODE

. CYCLE.ROLL.WITH.KEYS

F1=INCH.MODE

Pressing the F1 key will let the

operator select a jog mode type,

continuous or jog to length. In the

continuous mode, the servo will

run at a slow rate of speed until the

button is released. In the jog to length

mode, the servo will run at a slow rate

of speed until the job number feed

length is reached then it will stop.

The key has to be released and

depressed to jog again.

Depressing the F2 key will direct the

servo to feed forward and pressing

the F3 key will direct the servo to

feed in reverse.

. JOG!.TYPE=CONTINUOUS

. F1=ALTER.TYPE.OF.JOG

. F2=FORWARD.F3=BACKUP

. F4=EXIT.(INCH.MODE)

Pressing the F4 key once will reset

the program to the jog mode screen

so that jog is now active. Pressing the

F4 key twice will reset the program to

the manual mode screen. If the F4 key

was pressed twice then the following

screen is displayed.