Troubleshooting, Continued) – Rapid-Air SERVO FEED / RAPID MASTER User Manual

Page 14

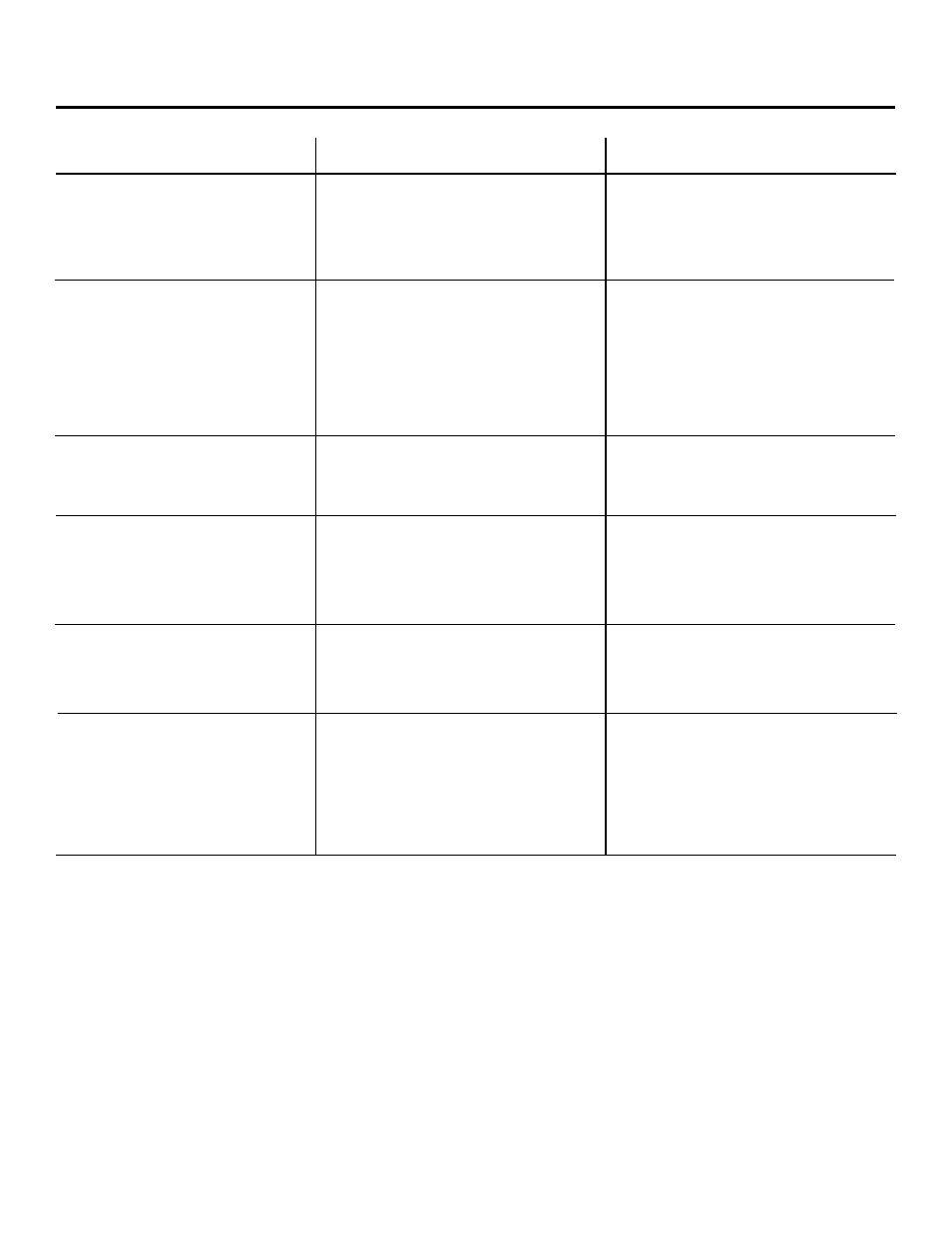

Material feeds off center

No automatic cycle

Servo hum

Fault signal on Pac-Sci is displayed

Cannot program unit from display

Mechanical pilot release

sticks down

troubleshooting

(continued)

Problem. .................................Cause...............................................Remedy

– Edge guides not set properly

– Material not centered to feed

– Bad material

– No press signal

– Controller fault

– Servo fault

– Program error

– Servo velocity gain too high

– Belt too loose or tight

– Servo fault

– Material jam

– Power surge / failure

– Program fault

– Data Instruments interface

jumper loose

– Too much overtravel

– Broken spring

– Needs lube

– Set edge guides

– Center material

– Try new roll of material

– Check limit switch input to

servo control

– Check lights on drive

– Check lights on drive

– Check parameters on display

– Consult factory

– Readjust belt tension

– Recycle power

– Check die

– Check / recycle power

– Check Pac-Sci & call factory

– Check Data Instruments connection

– Restrict travel of mechanical

actuating arm

– Remove plate and check springs

– Remove plate and lubricate

release bar