Set-up, Mechanical.set-up.of.die.or.punch – Rapid-Air SERVO FEED / RAPID MASTER User Manual

Page 21

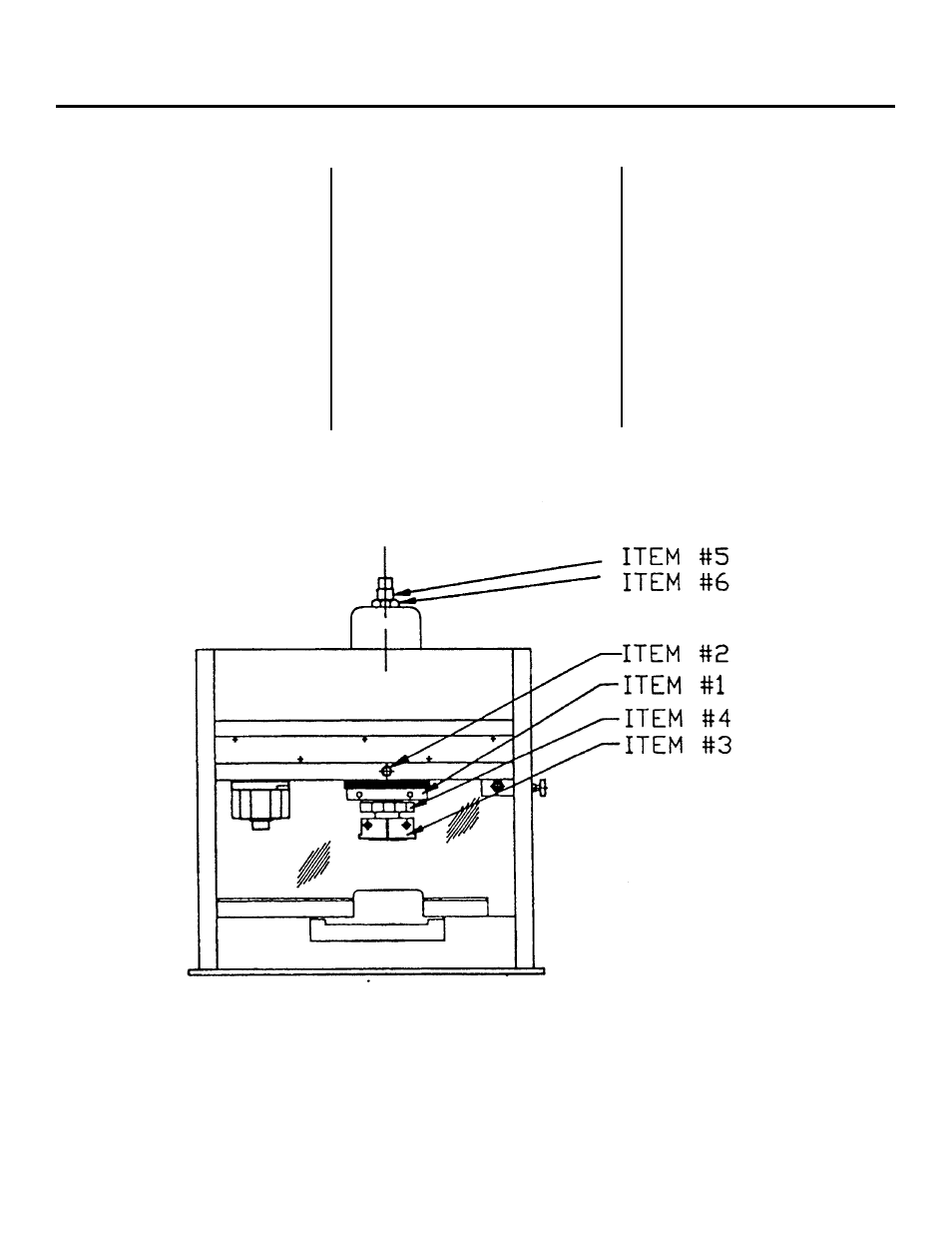

1) Secure the die set to the bolster

plate.

2) The piston adjustment sleeve

(item #1), establishes the stroke to

a maximum of .50 inches when fully

extended. The stroke is reduced by

1.8 inches with each full inward

rotation, using the 3-3/4 spanner

wrench provided. The piston stroke

adjustment sleeve is locked in place

with a nylon tipped set screw (item #2).

3) Lift the punch holder plate and

loosely connect it to the inner shaft

ram adjustment screw with the two

half shell clamps (item #3) provided.

4) Adjust the inner shaft (item #4) for

proper open height, using the

wrench provided.

5) Tightly secure the punch holder

plate to the inner shaft.

6) Lower the piston, piston shaft and

piston sleeve by rotating the

adjustment screw on top of the

head assembly (item #5) with the

crank provided. This is done to

check the full stroke set up. If all

adjustment are within limits, the top

adjustment screw should be

retracted to fully raise the piston

and ram assembly.

7) Lock the upper adjustment screw

(item #6) in the up position.

set-up

Mechanical.Set-Up.Of.Die.Or.Punch