Rapid-Air SERVO FEED WITH TRANSTERM: C, S, X, HT SERIES User Manual

Page 22

21

If this screen is displayed then the control cabinet has to be opened and the Pac-Sci drive

has to be checked. To reset the fault, the master on-off switch has to be cycled which will

reset the controller. The material path should be checked for obstruction and parallelism to

the die. If all this seems to be satisfactory and another fault occurs the factory should be

consulted.

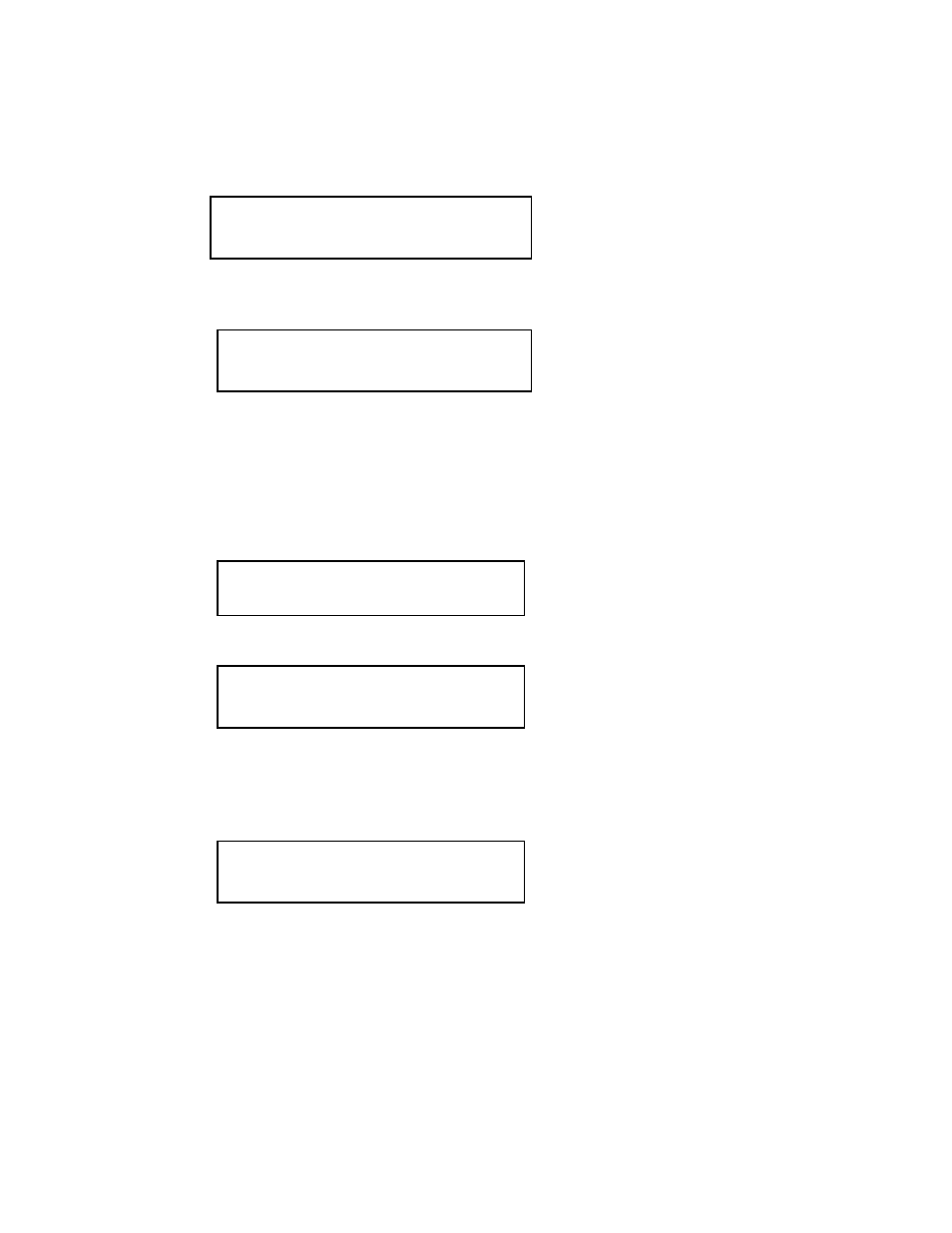

MODE SELECT F1=JOB#

F2=MAN F3=AUTO F4=REVIEW

The last section to be covered is the RAMP section. To get into this mode, press the black

pushbutton and the following screen appears.

RAMP PARAMETERS F1=ACCEL

F2=DECEL F3=TYPE F4=EXIT

F1=ACCEL

The only section that has not been covered in this write up is the ramp adjust mode. The

ramp adjusts how fast the servo motor gets up to speed and how fast it stops. This feature

is an asset that is seldom adjusted but can be a sure cure if material slippage seems to be a

problem. With the main menu screen displayed the key labeled ramp is active. Pressing

the accel key produces this display.

ACCEL MAX 75000 RMP/SEC

% MAX DECEL=000% F4=EXIT

Presing the F2 decel produces the following display.

DECEL MAX 75000 RPM?SEC

% MAX DECEL=000% F4=EXIT

The ramp usually is factory set at .015 on the series 100 drives and .035 on the series 200 &

300 drives. There is some deviation to this when the factory runs the unit, but this is a basic

starting point. Once the ramps have been set then press F3 on the keypad to display the

following screen.

ENTER=ACCEL RAMP TYPE=0

JERK=0 S_CURV=1 F4=EXIT

Although this screen has a decision to be made, we have found that for most standard

applications that entering a “0” - jerk mode gives the best running results. We ask that if

changing the ramp parameters, it is a good idea to also reconfirm the type being used-jerk

mode. Press F4 twice to get back to the main menu and then the programming procedure

section is complete.