Ramsey Winch RPH 8000T User Manual

Page 14

13

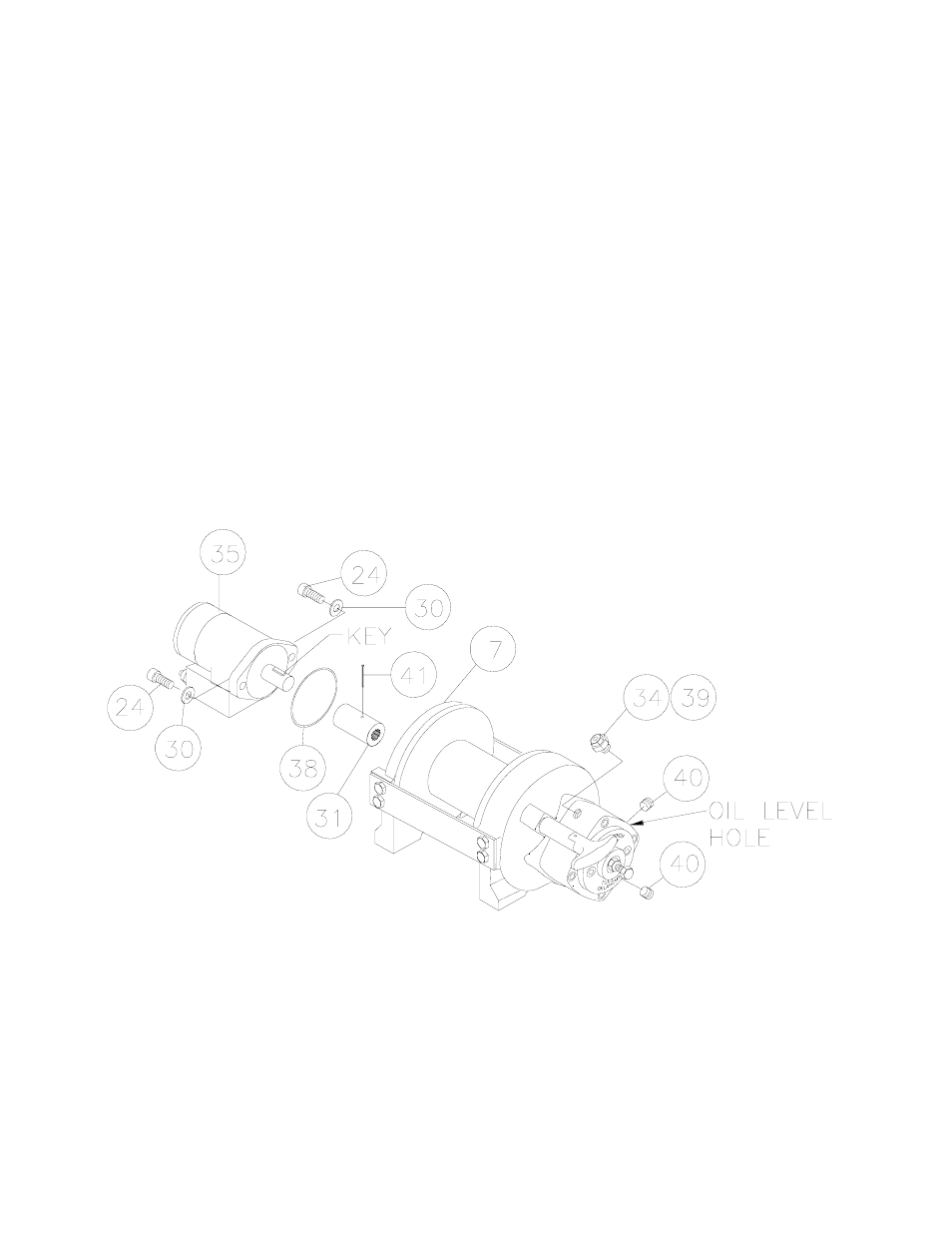

Before installing motor, check brake adjustment (refer to page 7 - ADJUSTING THE BRAKE).

Place splined end of coupling (item #31), with spirol pin (item #41) installed, inside of motor end bearing

housing (item #7) and slide over splines on end of input shaft. Place o-ring (item #38) around motor pilot.

Mount motor (item #35) to end bearing by aligning key on motor shaft with keyway in coupling. Be sure that

motor mounts flush to end bearing and that o-ring is set securely in place between motor and end bearing.

Secure motor to end bearing using two capscrews and lockwashers (items #24 & #30). Tighten capscrews to

49 ft.lbs. (66 Nm). Thread plug (item #40) into bottom of brake housing. Permatex can be added to threads of

plug to help in sealing. Pour a mixture of 8 oz. of high performance tractor transmission fluid, (Mobilfluid 424,

Phillips HG Fluid, Texaco TDH, Shell Oil Co. Donax TD, or equivalent) and 1/4 oz. of an additive (available

from the factory) into oil level hole. Oil level should be kept at oil level hole (plus or minus 1/8"). Thread plug

(item #40) into oil level hole. Insert reducer (item #39) into hole in top of brake housing and breather plug (item

#34) into reducer. Tighten plugs and reducer securely.