Ramsey Winch QM-8000 User Manual

Page 5

Installation

The Quick Mount is solely and exclusively designed for vehicle

mounted, non-industrial applications. All other applications will

void warranty.

The Quick Mount must be front mounted with a front receiver

hitch available from Ramsey for selected vehicles. For rear

mounting of the QM, a SurePull Class III rear receiver or equiv-

alent with a 5,000 lb. minimum weight carrying rating must be

used.

For normal self recovery work, your existing electrical system is

adequate. Your battery must be kept in good condition. A fully

charged battery and proper connections are essential.

For front mounting, route quick connect battery power lead

through grille, leaving connector on outside and connect red

cable to positive(+) terminal and black cable to negative(-) ter-

minal of battery. Secure cable under hood with cable ties.

For rear mounting connect battery power lead as instructed

above. Secure cables under vehicle away from moving parts

and exhaust system. Terminate routing near the center of the

vehicle at the rear. BE SURE BATTERY CABLES ARE NOT

DRAWN TAUT ACROSS ANY SURFACES WHICH COULD POS-

SIBLY DAMAGE THEM.

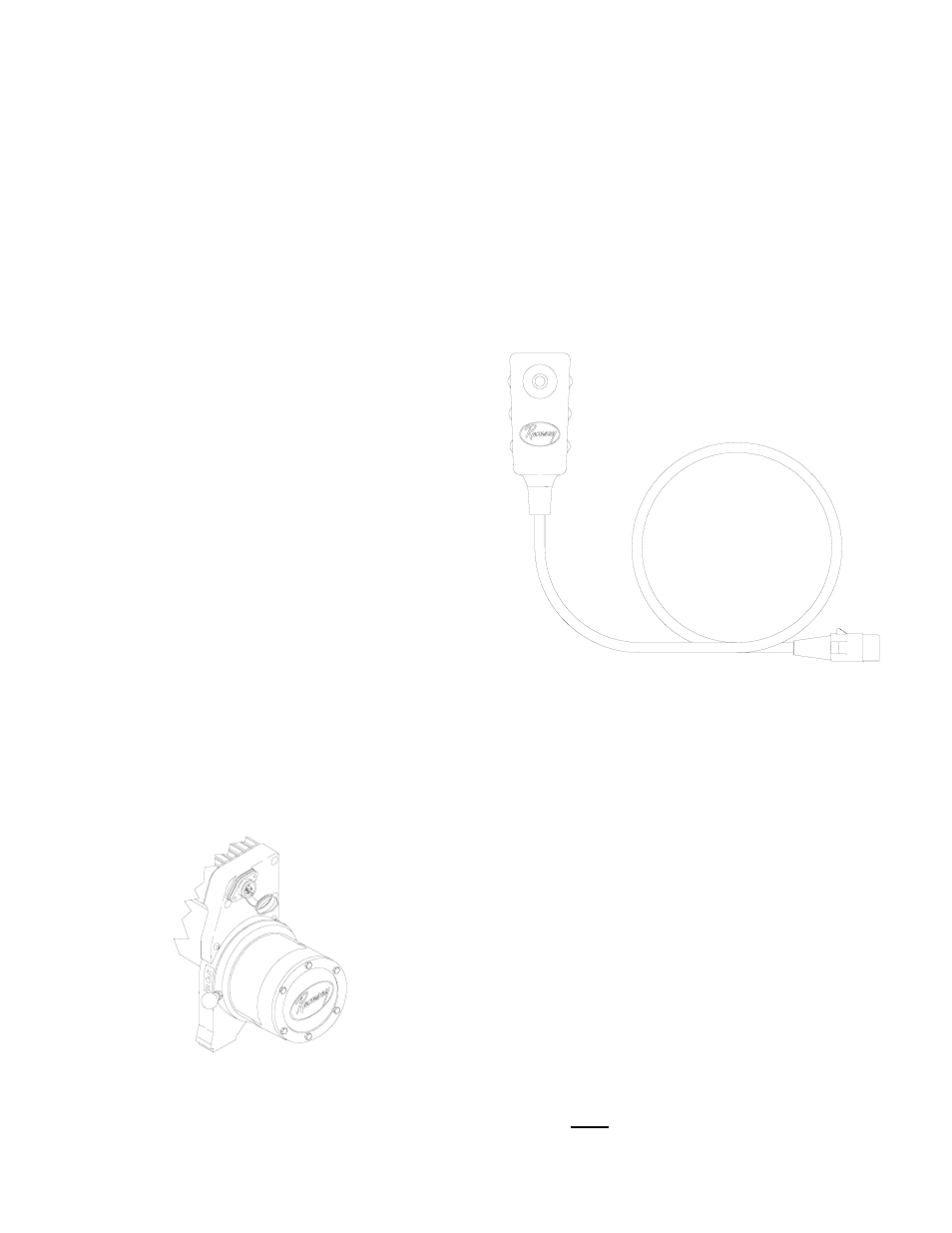

Secure Quick Mount in the receiver with the Ramsey locking

pin. Connect quick disconnect from Quick Mount winch to bat-

tery power lead. Plug remote switch into receptacle on

solenoid assembly.

Clutch Operation

The winch clutch allows rapid unspooling of the cable for hook-

ing onto the load or anchor point. The clutch is operated by the

shifter tab located on the gear housing end of the winch.

Disengage the clutch (move the clutch shifter tab to the "OUT"

position). Free spool some cable off the drum. Engage the

clutch (move the clutch shifter tab to the "IN" position).

Remote Control Switch Operation

The remote control switch is waterproof and has push button

stations on either side. It is designed this way to prevent quick

winch reversals which lead to premature solenoid failure. The

switch is also color coded to aid you in not having to guess at

the direction your winch willl run. Make sure the motor has

stopped fully before reversing. Run the winch forward and

reverse to check connections. Snap appropriate plastic disc

into proper thumb button cavity on remote switch after deter-

mining direction of rotation for winch drum.

DO NOT LEAVE SWITCH PLUGGED IN WHEN WINCH IS NOT IN

USE.

Maintenance

Corrosion on electrical connections will reduce performance or

may cause a short. Clean all connections, especially in remote

control switch and receptacle. In salty environments use a sil-

icone sealer to protect from corrosion.

All moving parts in the winch are permanently lubricated with

high temperature lithium grease at the time of assembly. Under

normal conditions, factory lubrication will suffice.

Lubricate the cable periodically using light penetrating oil. If the

cable becomes worn or damaged it must be replaced. Inspect

for broken strands and replace if necessary (see the next sec-

tion for cable replacement instructions).

To minimize corrosion of the internal motor components that

may occur due to condensation, power the winch in or out peri-

odically. Energizing the motor will generate heat, which will help

dissipate any moisture buildup in the motor. This should be per-

formed at periodic intervals. (such as with each oil change to

your vehicle. Note: Refer to Troubleshooting Guide if motor has

been submerged.

5