Installation, Connection diagrams, Power wave – Lincoln Electric IM10007 POWER WAVE S350 User Manual

Page 12: S350, Figure a.2 figure a.3

A-5

INSTALLATION

POWER WAVE

®

S350

A-5

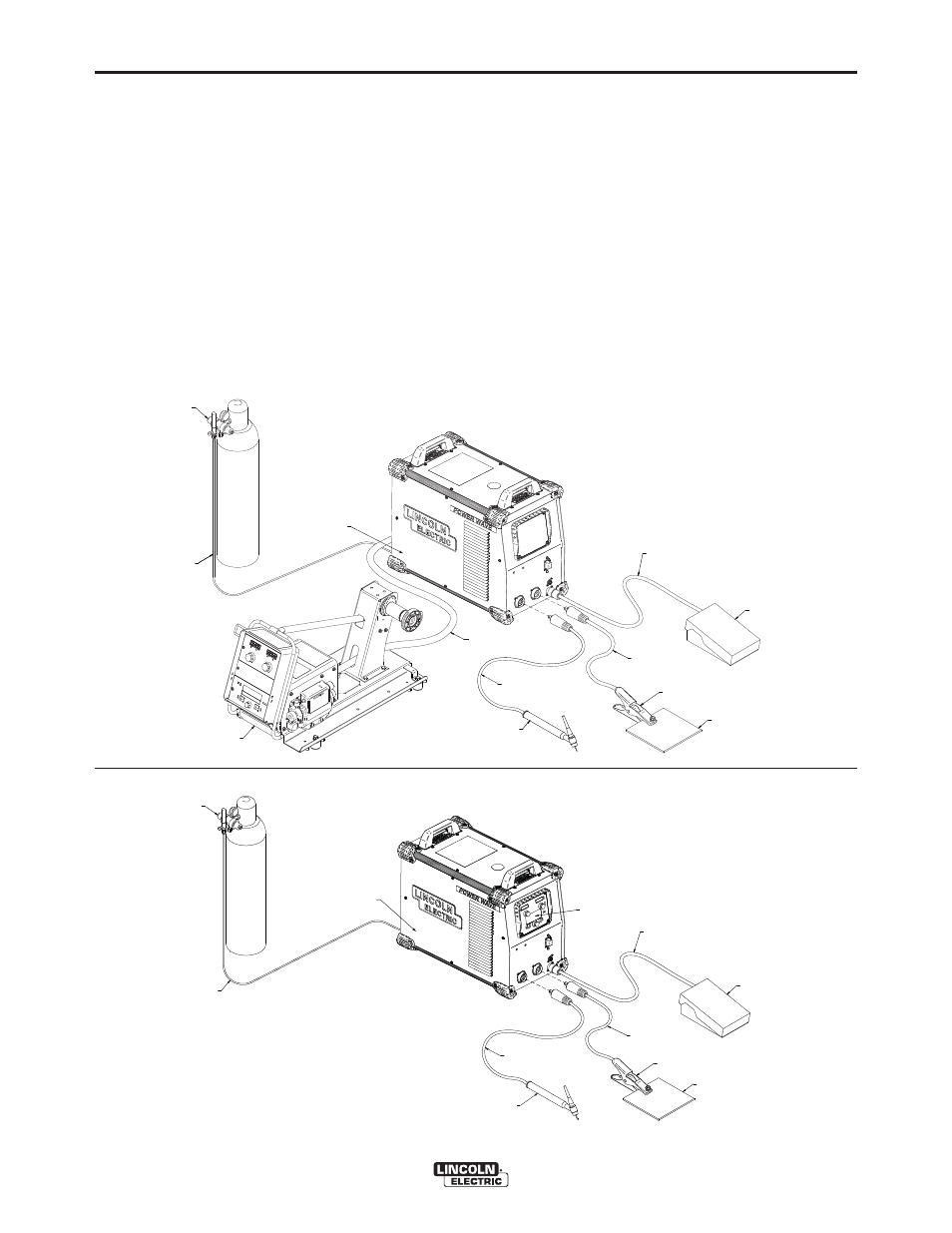

CONNECTION DIAGRAMS

GTAW (TIG) WELDING

A user interface is required for adjusting the TIG weld-

ing settings. A Power Feed wire feeder can be used as

the user interface (Figure A.2), or a S-series user inter-

face (K2828-1) can be installed into the power source

(Figure A.3). Refer to the connection diagrams based

on the user interface that is being used. For either set-

up the K2825-1 solenoid kit is recommended for con-

trolling the gas. Alternate configurations are possible

depending on the wire feeder that is being used. Refer

to the wire feederʼs manual for alternative configura-

tions.

SMAW (STICK) WELDING

Similar to TIG welding a user interface is required for

adjusting the Stick welding settings. A Power Feed

wire feeder can be used as the user interface, or a

K2828-1 (user interface control panel) can be installed

into the power source (Figure A.4). The connection

diagram shown is based on the S-Series user inter-

face (K2828-1). In this diagram the remote control box

is optional.

GMAW (MIG) WELDING

An arclink compatible wire feeder is recommended for

Mig welding. Refer to Figure A.5 for the connection

details.

REGULATOR

FLOWMETER

FOOT AMPTROL

K87

870

WORK CLAMP

TO POSITIVE

(+) STUD

TO REMOTE CONTROL

RECEPTACLE

PF10-M

WIRE FEEDER

ARCLINK CABLE

K1543-[XX]

GAS HOSE

GAS SOLENOID KIT

TIG WITH POWER FEED USER INTERFACE

(INSIDE MACHINE)

K2825-1

TO NEGATIVE

(-) STUD

TIG TORCH

K2266-1 KIT

(INCLUDES WORK CLAMP,

ADAPTER, AND REGULATOR)

WORK PIECE

FOOT AMPTROL

K870

WORK PIECE

WORK CLAMP

TIG TORCH

K2266-1 KIT

(INCLUDES WORK CLAMP,

ADAPTER, AND REGULATOR)

TO POSITIVE

(+) STUD

TO REMOTE CONTROL

RECEPTACLE

USER INTERFACE

CONTROL PANEL

K2828-1

GAS SOLENOID KIT

TIG WITH S-SERIES USER INTERFACE

(INSIDE MACHINE)

K2825-1

TO NEGATIVE

(-) STUD

REGULATOR

FLOWMETER

GAS HOSE

FIGURE A.2

FIGURE A.3