Operation, Design features, Case front controls – Lincoln Electric IM10133 POWER WAVE R500 User Manual

Page 20

3. FEEDER STATUS LED - A two color LED that

indicates system errors. The Power Wave R500 is

equipped with two indicators. One is for the invert-

er power source, while the other indicates the sta-

tus of the feeder control system. Normal operation

is a steady green light. For more information and a

detailed listing, see the troubleshooting section of

this document or the Service Manual for this

machine. (See Troubleshooting Section for

operational functions.)

NOTE: The Power Wave R500 status light will flash

green, and sometimes red and green, for up to one

minute when the machine is first turned on. This is a

normal situation as the machine goes through a self

test at power up.

4. POWER SWITCH - Controls power to the POWER

WAVE

®

R500.

5. NEGATIVE WELD OUTPUT

6. POSITIVE WELD OUTPUT

7. VOLTAGE SENSE CONNECTOR: Allows for sep-

arate remote electrode and work sense leads.

Pin

Lead

Function

3

21

Work Voltage Sense

1

67E

Electrode Voltage Sense

B-3

OPERATION

B-3

DESIGN FEATURES

Loaded with Standard Features

• Multiple process DC output range: 5 - 550 Amps

• 200 – 600 VAC, 3 phase, 50-60Hz input power

• New and Improved Line Voltage Compensation

holds the output constant over wide input voltage

fluctuations.

• Utilizes next generation microprocessor control,

based on the ArcLink

®

platform.

• State of the art power electronics technology yields

superior welding capability.

• Electronic over current protection

• Input over voltage protection.

• F.A.N. (fan as needed). Cooling fan only runs

when needed.

• Thermostatically protected for safety and reliability.

• Ethernet connectivity.

• Panel mounted Status and Thermal LED indicators

facilitate quick and easy troubleshooting.

• Potted PC boards for enhanced ruggedness/relia-

bility.

• Enclosure reinforced with heavy duty aluminum

extrusions for mechanical toughness

• Waveform Control Technology™ for good weld

appearance and low spatter, even when welding

nickel alloys.

• Sync Tandem installed.

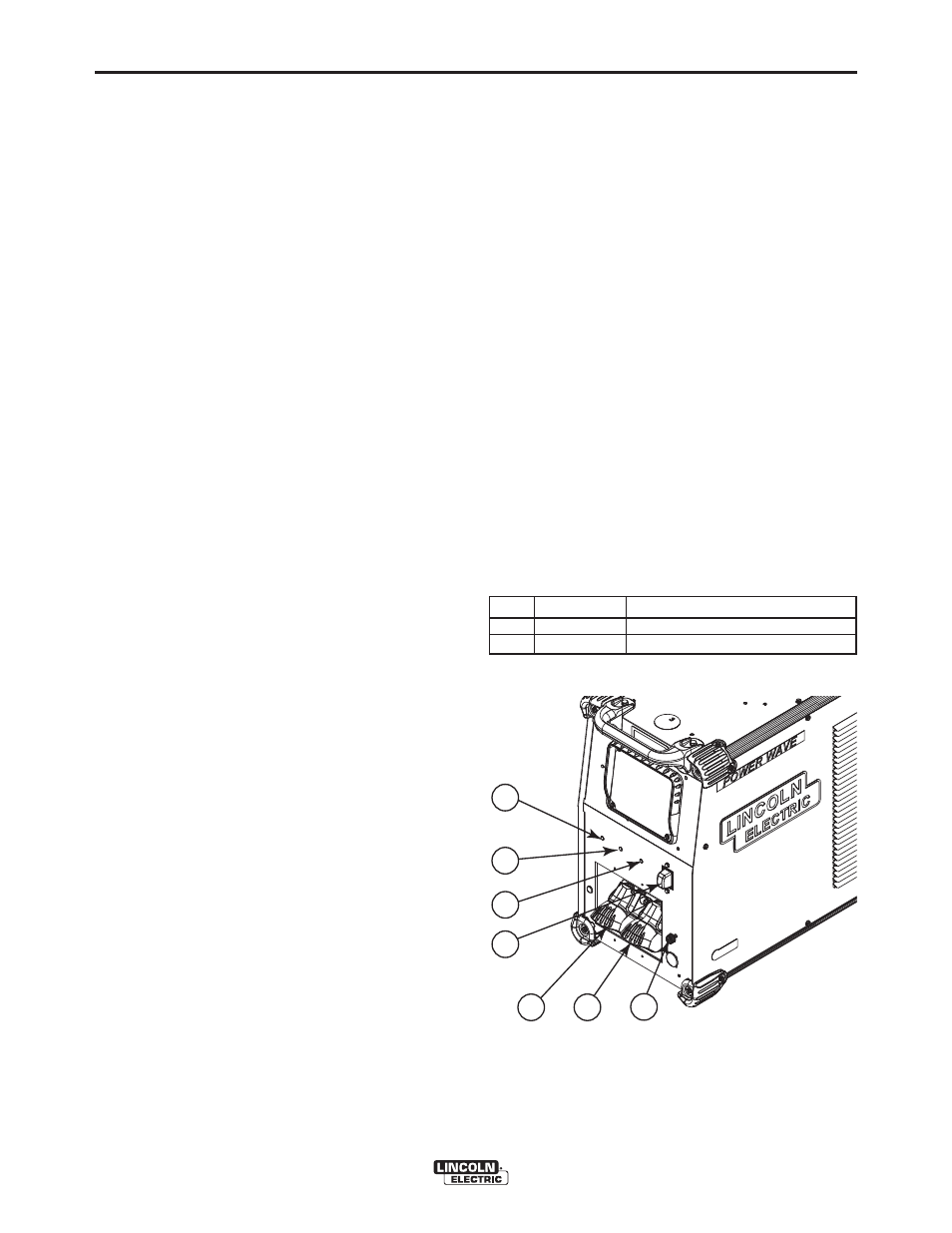

CASE FRONT CONTROLS

(See Figure B.1)

1. STATUS LED - (See Troubleshooting Section for

operational functions).

2. THERMAL LED - Indicates when machine has

thermal fault.

POWER WAVE

®

R500

1

4

5

7

2

3

6

FIGURE B.1