Troubleshooting, Caution – Lincoln Electric IM10096 POWER MIG 256 User Manual

Page 29

E-3

E-3

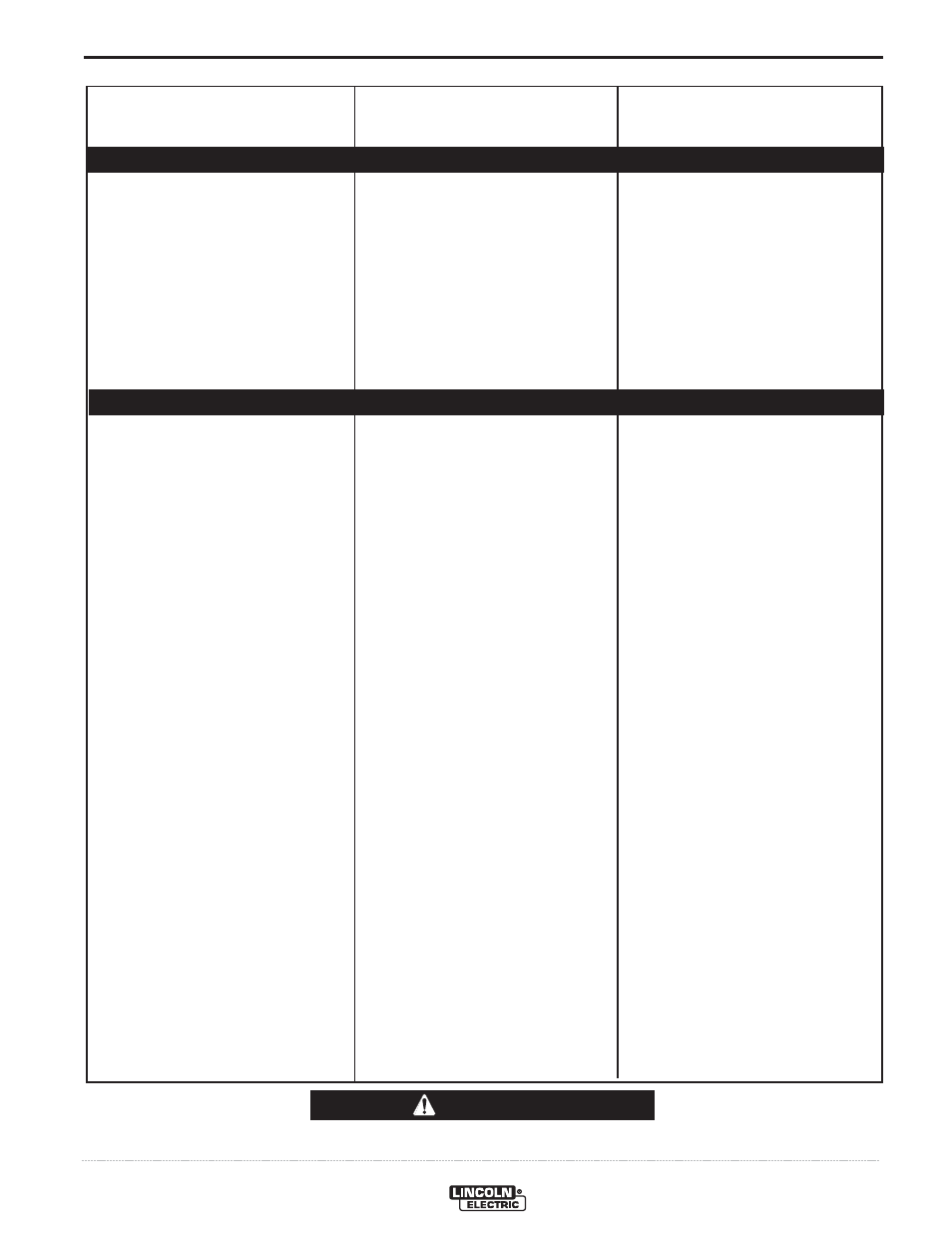

TROUBLESHOOTING

PROBLEMS

(SYMPTOMS)

Poor arc striking with electrode

sticking or blasting off.

Rough wire feeding or wire will not

feed but drive rolls are turning.

POSSIBLE

CAUSE

1. Make sure settings for wire feed

speed and voltage are correct

for process being used.

2. The gas shielding may be

improper for process being used.

3. Check input line voltage to be

within machineʼs recommended

rating range.

4. Check that the machine recon-

nect panel is configured properly

for the applied voltage.

1. The gun cable may be kinked or twisted.

2. The wire may be jammed in the gun

cable, or gun cable may be dirty.

3. Check drive roll tension and

position of grooves.

4. Check for worn or loose drive rolls.

5. The electrode may be rusty or dirty.

6. Check for damaged or incorrect

contact tip.

7. Check wire spindle for ease of

rotation and adjust break ten-

sion knob if necessary.

8. Check that the gun is pushed all

the way into gun mount and

properly seated.

RECOMMENDED

COURSE OF ACTION

If all recommended possible areas

of misadjustment have been

checked and the problem persists,

Contact your local Lincoln

Authorized Field Service Facility.

OUTPUT PROBLEMS

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

LOCAL AUTHORIZED LINCOLN ELECTRIC FIELD SERVICE FACILITY for assistance before you proceed.

CAUTION

FEEDING PROBLEMS

Observe all Safety Guidelines detailed throughout this manual

POWER MIG

®

256