Accessories, Making a weld with the magnum sg spool gun, Caution – Lincoln Electric IM10096 POWER MIG 256 User Manual

Page 23

C-3

C-3

See the following procedure for setting the Wire

Speed Feed using the Magnum SG Spool Gun:

To determine spool gun wire feed speed use a hand

tachometer, or calculate the speed using the following

equation:

IPM= Length of wire fed (inches) x 60

Time fed (seconds)

4. To return to normal POWER MIG

®

256 welding,

release the spool gun trigger and reset feeder gun

welding procedures.

4. The following procedure settings for Aluminum

4043 can be used as initial settings for making test

welds to determine final settings:

5. To return to normal POWER MIG

®

256 welding,

release the spool gun trigger and reset feeder gun

voltage procedure setting if necessary.

MAKING A WELD WITH THE

MAGNUM SG SPOOL GUN

The POWER MIG

®

256 control circuitry is designed to

sense either the spool gun or (built in) wire feeder

trigger circuitry. The spool gun can easily be plugged

in and will be ready to use.

Closing either gun trigger will cause the electrode

of both guns to be electrically "HOT". Be sure

unused gun is positioned so electrode or tip will

not contact metal case or other metal common to

work.

1. Pulling the trigger for the built-in feeder gun:

• Disables spool gun operation.

• Closing feeder gun trigger starts feeder gun

welding and makes both electrodes electrically

"HOT".

2. Pulling SPOOL GUN Trigger:

• Disables built-in feeder gun operation.

• Closing spool gun trigger starts spool gun weld-

ing and makes both electrodes electrically

"HOT".

3. Operation with POWER MIG

®

256:

• Turn the POWER MIG

®

256 input power ON.

• Adjusting the voltage control will increase or

decrease your welding voltage.

• Adjusting the wire speed control on the spool gun

will increase or decrease the spool gun wire feed

speed.

• For the Magnum SG Spool Gun, the wire feed

speed is controlled by combination of the wire

feed speed displayed on the POWER MIG

®

256

and the wire speed control on the spool gun.

POWER MIG

®

256

ACCESSORIES

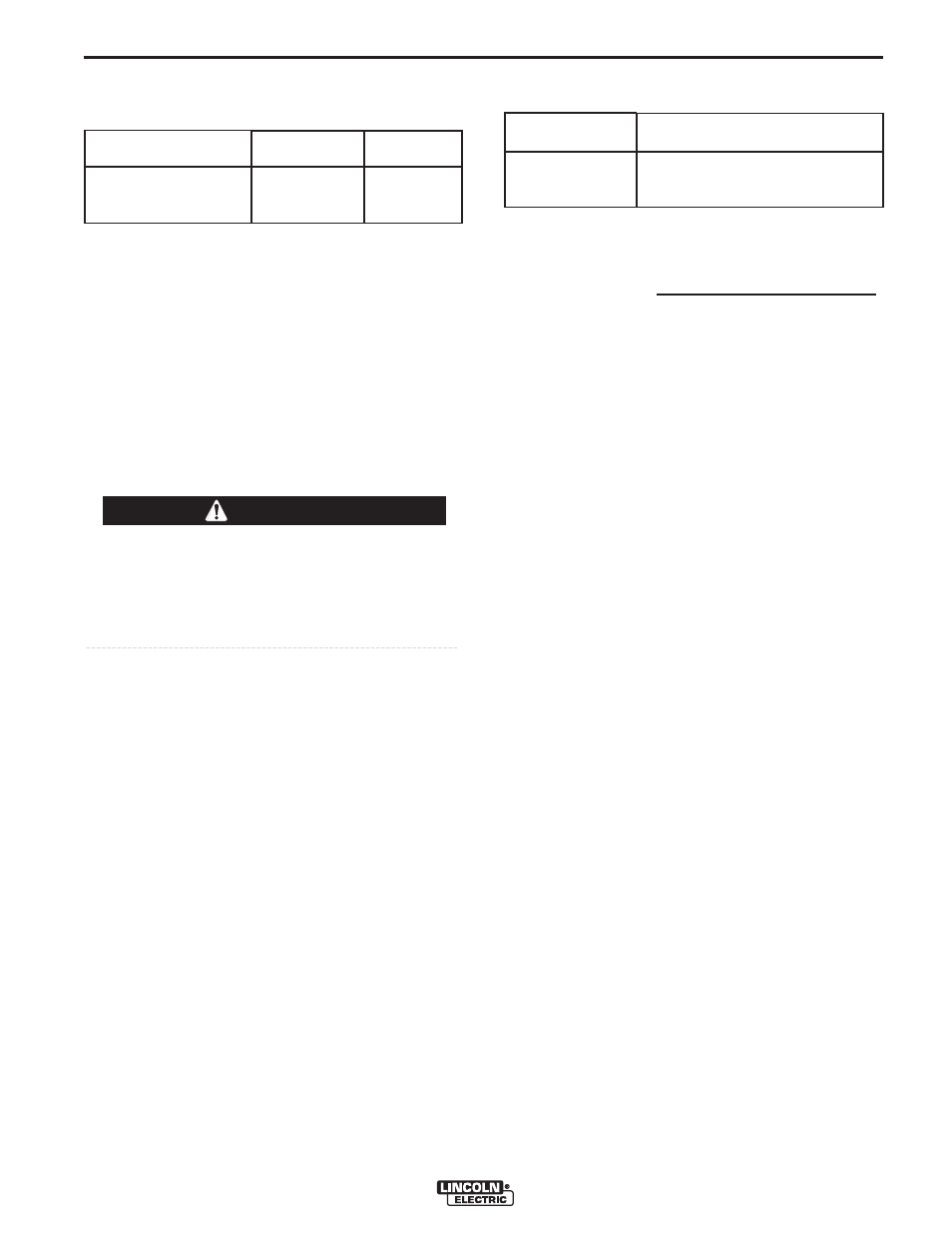

Wire Diameter

In. (mm)

.030” (.8mm)

.035” (.9mm)

3/64” (1.2mm)

Wire Feed Speed

Display

270

250

240

Arc voltage

Setting

15V

16V

20V

CAUTION

Wire Feed Speed

Display

50

300

700

SG Spool Gun Wire Feed Speed

Approximate Range

50-200

200-400

300-600