Installation, Gun and cable installation, Warning – Lincoln Electric IM10105 POWER MIG 350MP User Manual

Page 11: Shielding gas, Gun & cable assembly installed into the power mig

A-4

GUN AND CABLE INSTALLATION

A Magnum 300 gun and 15Ft.(4.6m) cable are provid-

ed with the POWER MIG

®

350MP. A Magnum cable

liner for .035-.045" (0.9-1.2 mm) electrode and con-

tact tips for .035” (0.9mm) and .045” (1.2mm) are

included for 15Ft..

Turn the welder power switch off before installing

gun and cable.

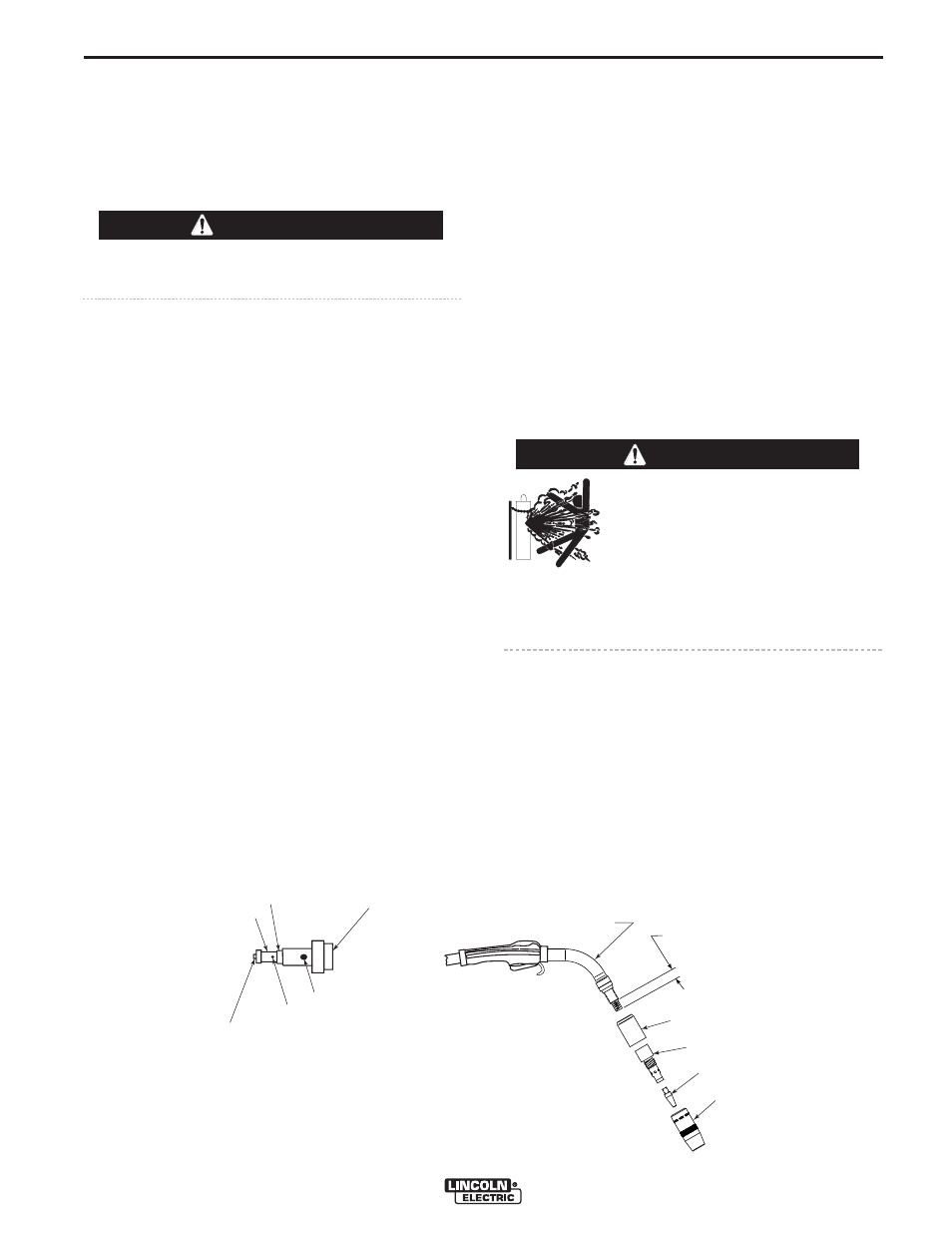

LINER INSTALLATION AND TRIMMING

INSTRUCTION (SEE FIGURE A.3)

1. Remove the gas nozzle.

2. Remove the gas diffuser from the gun tube.

3. Lay gun and cable out straight on a flat surface.

Loosen set screw of the connector on the back end

of the gun.

4. Insert the untrimmed Liner into the back end of the

gun.

5. Seat Liner bushing into back of gun. Secure Liner

by tightening set screw. Do not install the gas dif-

fuser at this time.

6. Lay the cable straight and trim Liner to 9/16”.

Remove burrs.

7. Install insulator and secure the gas diffuser into the

tube.

GUN & CABLE ASSEMBLY INSTALLED

INTO THE POWER MIG

®

1. Unscrew knurled screw on the drive unit front end

(inside wire feed compartment) until tip of screw no

longer protrudes into gun opening as seen from

front of machine.

WARNING

A-4

INSTALLATION

2. Insert the male end of gun cable into the female

casting through opening in front panel. Make sure

connector is fully inserted and tighten knurled

screw.

3. Connect the gun trigger connector from the gun

and cable to the mating receptacle inside the com-

partment located above the gun connection made

in step 2 above. Make sure that the key ways are

aligned, insert and tighten retaining ring.

SHIELDING GAS

(For Gas Metal Arc Welding Processes)

Customer must provide cylinder of appropriate type

shielding gas for the process being used.

A gas flow regulator, for CO

2

or Argon blend gas, and

an inlet gas hose are factory provided with the

POWER MIG

®

350MP.

Install shielding gas supply as follows:

1. Set gas cylinder on rear platform of POWER MIG

®

350MP. Hook chain in place to secure cylinder to

rear of welder.

2. Remove the cylinder cap. Inspect the cylinder

valves and regulator for damaged threads, dirt,

dust, oil or grease. Remove dust and dirt with a

clean cloth.

WARNING

CYLINDER may explode if

damaged.

• Gas under pressure is explosive.

Always keep gas cylinders in an

upright position and always keep

chained to undercarriage or sta-

tionary support. See American

National Standard Z-49.1, “Safety

in Welding and Cutting” published

by the American Welding Society.

.56" (14.2mm)

LINER TRIM

LENGTH

Gun Tube

Assembly

Insulator

Gas Diffuser

Gas Nozzle

Contact Tip

INSULATION TUBE

FEEDER END

CABLE HANDLE

BRASS CABLE

CONNECTOR

SET SCREW

MOLDED GAS PLUG

LINER ASSEMBLY(LINER BUSHING TO BE SEATED

TIGHT AGIANST BRASS CABLE CONNECTOR)

FIGURE A.3

POWER MIG

®

350MP