Auto-ohm operating procedures – Vanguard Auto-Ohm User Manual

Page 8

Auto-Ohm Operating Procedures

4

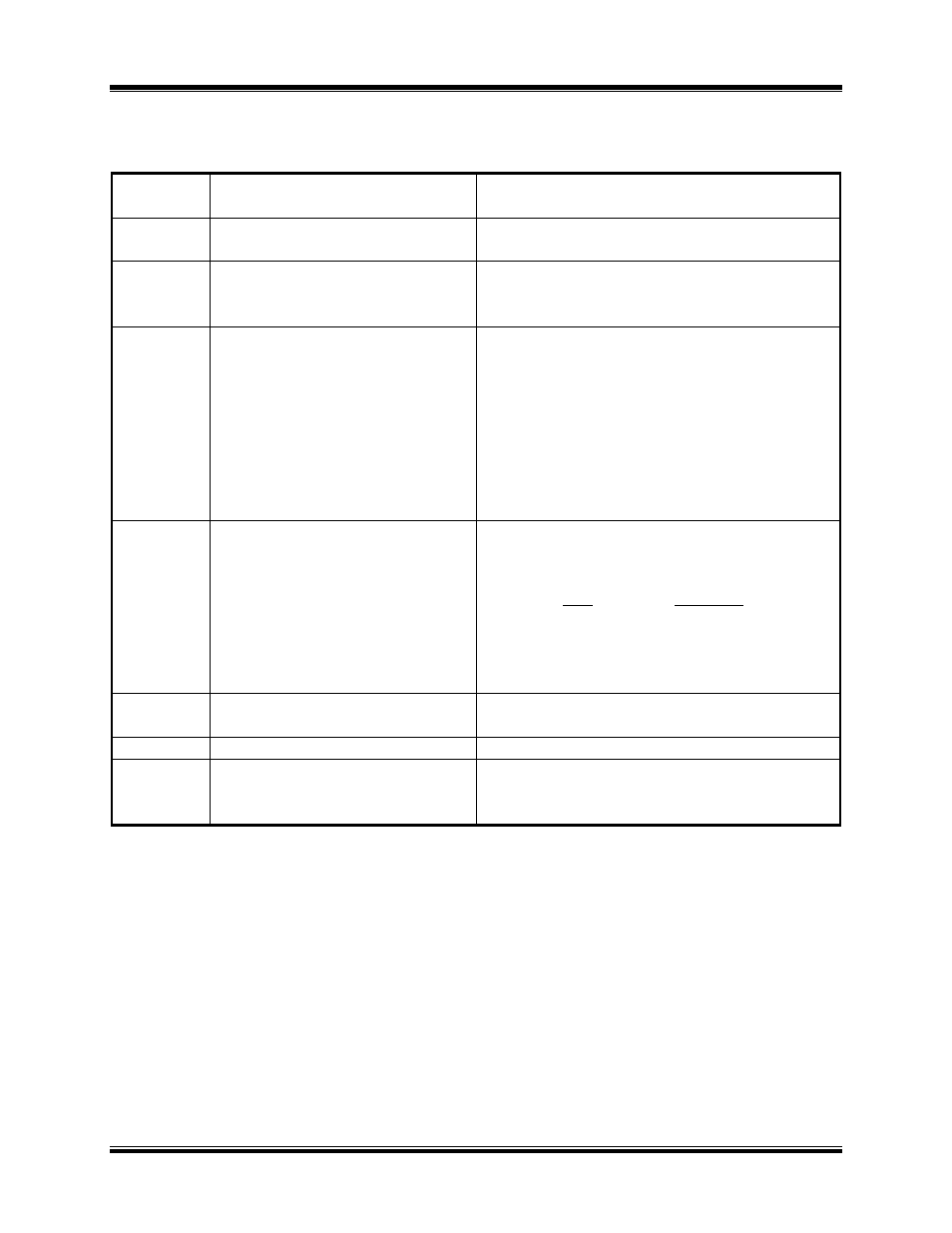

Table 2. Functional Description of Auto-Ohm Controls and Display

Figure 1

Index #

Adjacent Panel Marking

Functional Description

1

120/240 Vac, 8A, 50- 60 Hz

Input power connector with third-wire safety

ground and 10A built-in circuit breaker

2

no marking

LCD; 4-line by 16-character; back-lighted;

Displays menus of selections, operator

entries, and test-measurement results

3

CHANGE

“PUSH”

TO SELECT

One-knob control (all Auto-Ohm menus and

selections are controlled by this one control

knob). Turning this control knob scrolls

through different menu options (shown on

an LCD), which display. Pressing the knob

selects the displayed function, usually

producing a new menu of selectable options.

See Figure 2 for a summary of the step-by-

step operating procedures

4

RS-232C

RS-232C interface port; 9-pin connector;

female DB type. The data are set to 19,200

baud, 1 start bit, 8 data bits, and no parity bit;

PIN ................ SIGNAL

2 ................ Rx

3 ................ Tx

5 ................ Signal Gnd

5

HIGH CURRENT

PRESENT

LED indicator, red; Lights when high test

current is going through the test leads.

6

(resistor symbol)

Voltage-sensing connector jacks (red).

7

(None)

Current lead connectors (red); Female jacks

for heavy-gauge test cables, which conduct up

to 100 amperes of test current.