Sae j1628 recommended procedure – TIF ZX Heated Pentode Refrigerant Detector User Manual

Page 13

11

4 . In windy areas, even a large leak can be difficult to find . Under these conditions, it is

best to shield the potential leak area from wind or breezes .

5 . A leak is a constant source of refrigerant, and when a true leak source is located, it

should produce a repeatable alarm each time it is approached . Intermittent (non-

repeatable) alarms are often caused by accumulations of refrigerant near or around

leak points .

6 . If an alarm occurs, and cannot be repeated when the probe tip is placed at the

same point again, it is unlikely there is a significant leak present at that point .

However, this may be indicative of a leak nearby – and can be used as a diagnostic

aid in leak finding .

sae J1628 Recommended Procedure

NOTE: Leak test automotive A/C systems with the engine turned OFF.

1 . The air conditioning or refrigeration system should be charged with sufficient

refrigerant to have gauge pressure of at least 340 kPa (50 psi) when not in

operation . At temperature below 15°C (59°F), leaks may not be measurable, since

this pressure may not be reached .

2 . Do not contaminate the detector probe tip nor part being tested . If the part is

particularly dirty, or condensation (moisture) is present, clean it with a dry shop

towel or shop air . Do not use cleaners or solvents, since the detector may be

sensitive to their ingredients .

3 . Visually trace the entire refrigerant system, and look for signs of air conditioning

lubricant leakage, damage, and corrosion on all lines, hoses, and components .

Check each questionable area with the detector probe, as well as fittings, hose-to-

line couplings, refrigerant controls, service ports with caps in place, brazed or

welded areas, areas around attachment points, and hold-downs on lines and

components .

4 . Follow the refrigerant system around in a continuous path so no areas of potential

leaks are missed . If a leak is found, continue to test the remainder of the system .

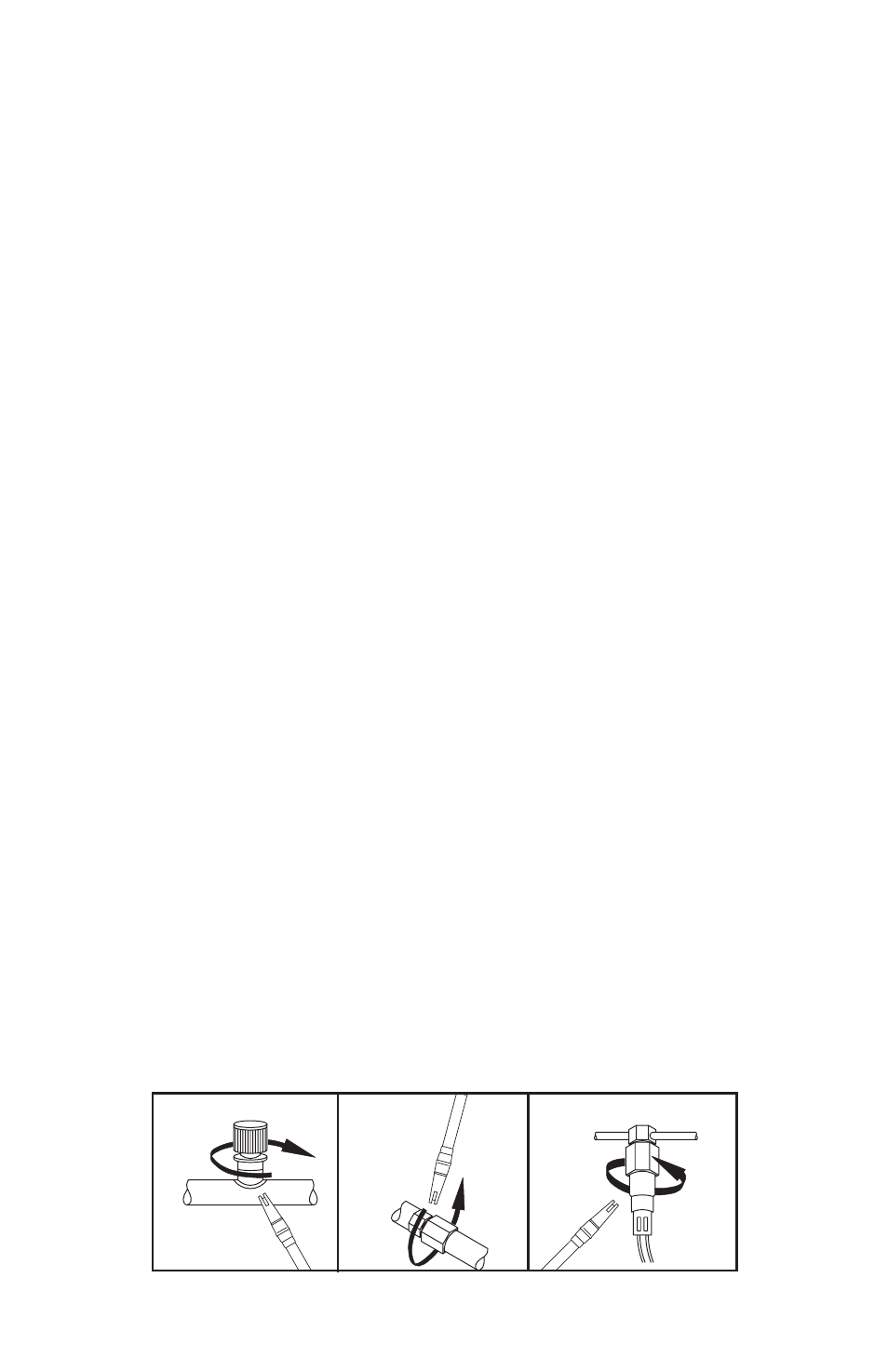

5 . At each area checked, move the probe around the location at a rate no more than

25 to 50 mm/second (1–2 inch/second), and no more than 5 mm (1/4 in .) from the

surface, and completely around the position . Slower and closer movement of the

probe greatly improves the likelihood of finding a leak (see Fig . 6) . Any increase in

the alarm rate is indicative of a leak .

Fig . 6