Heating cable installation, Sr heating cable selection and design (continued), Figure 1: cable placement on pipe – King Electric SR self-reg, cut to length User Manual

Page 5

CALCULATE THE TOTAL HEATING CABLE LENGTH

Cable length = A+B+C+D+E+F

A Pipe length x number of cables

B 4 ft. x number of valves

C 2 ft. x number of flanges, supports, etc.

D 1

ft. for each power connection

E 2 ft. for each splice connection

F 3 ft. for each tee connection

= Total heating cable length (ft)

EXAMPLE

Pipe size: 2” metal pipe

Lowest air temp: -20°F

Insulation thickness: 1”

Cable selection: (1) 5w/ft. (From table 1, pg 3)

Pipe length: 80 ft.

Valves: 2

Pipe supports: 12

Power connections: 1

Splice connections: 1

HEATING CABLE REQUIRED

A Pipe length x number of cables

80 ft. x 1 = 80 ft.

B 4 ft. x number of valves

4 ft. x 2 = 8 ft.

C 2 ft. x number of flanges, supports, etc. 2 ft. x 12 = 24 ft.

D 1

ft. for each power connection

1 ft. x 1 = 1 ft.

E 2 ft. for each splice connection.

1 ft. x 1 = 1 ft.

F 3 ft. for each tee connection

3 ft. x 0 = 0 ft.

= Total heating cable length (ft)

114 ft.

MAXIMUM CIRCUIT LENGTH ALLOWED

Ensure that your circuits do not exceed the maximum

circuit length listed in Table 3, page 4. If necessary,

use additional shorter circuits.

GENERAL NOTES

1. Verify that the heating cable is the correct length, wattage

and voltage prior to installation.

2. All welding, hydrostatic testing, and painting of the pipe

should be completed before the heating cable installation.

3. The piping system must be inspected to ensure that it is

clean, dry and has no sharp or jagged edges that could

potentially damage the heating cable.

4. Do not install the heat tracing before completion of the entire

piping system.

5. The cables must be installed a minimum of 10 inches away

from wood or any other combustible materials.

6. The minimum cable bending radius is 1/2 inch.

STEP 1: PREPARE FOR INSTALLATION

1.

Store the heating cable in a clean, dry place.

2.

Perform a pressure test on the pipe prior to cable installation.

3. Remove any sharp surfaces on the pipe that could potentially

damage the outer jacket of the heating cable.

4. Walk the pipe system and plan the routing of the heating

cable on the pipe.

STEP2: CUT THE HEATING CABLE TO LENGTH

1.

Cut the heating cable to length required. This can be done

before or after the cable is attached to the pipe.

2. Leave a minimum of 1 foot extra heating cable for connection

to the supply power.

3. For splice and tee connections, leave a minimum of 1 foot for

each section of heating cable.

4. King SR heating cable can to length without affecting its heat

output per foot.

5. When splicing and terminating be sure to protect the cable

ends from moisture, contaminants and mechanical damage.

Heating Cable Installation

STEP 3: ATTACH THE CABLE TO THE PIPE

1

. Verify pipe to be traced is completely dry.

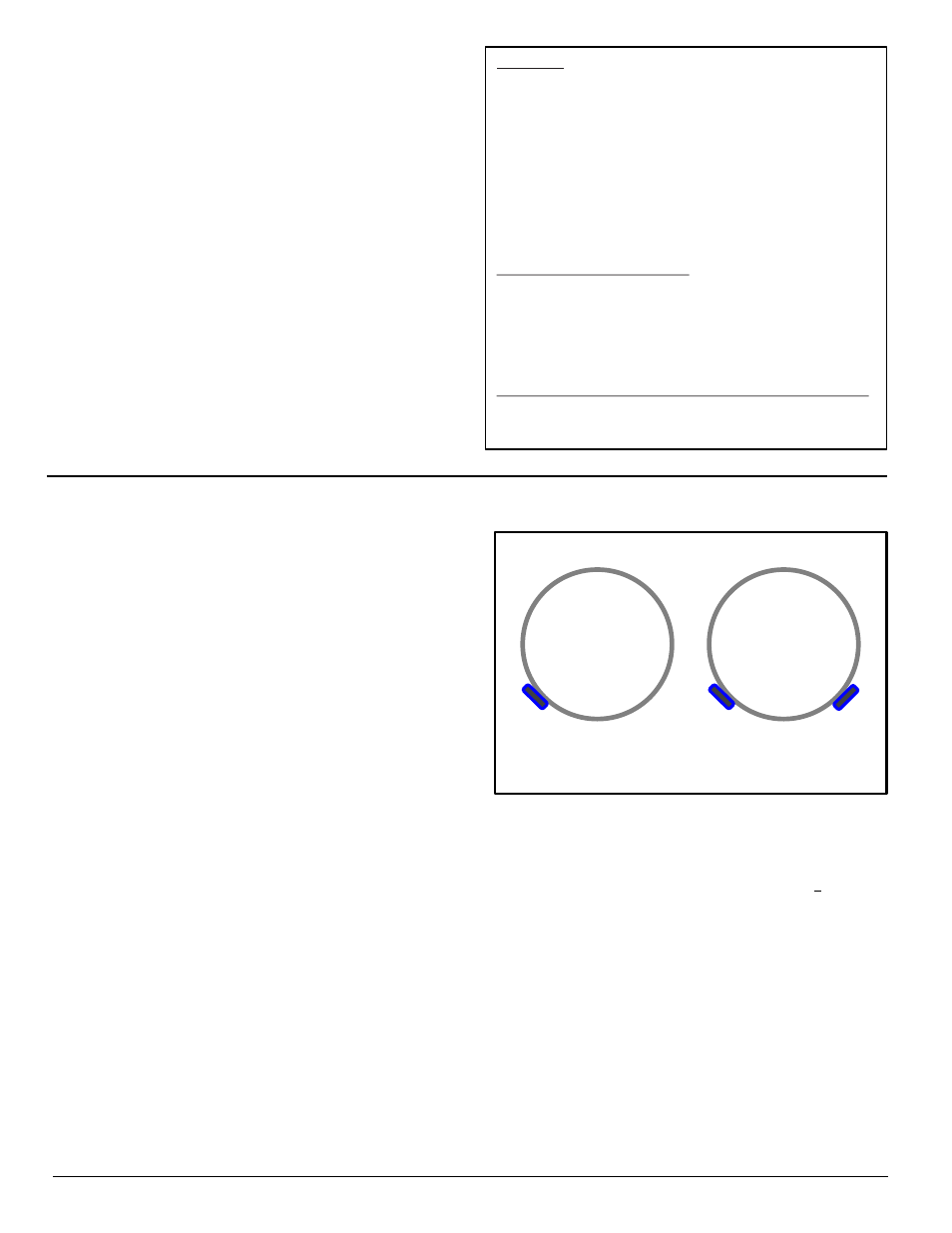

2. For straight tracing, install the heating cable on a the lower

half of the pipe; for example, in the 4 o’clock

or 8 o’clock

position as shown

in Figure

1.

3. Install the extra heating cable as required for valves,

flanges, etc.

4. Spiral tracing is not recommended as it is labor intensive

.

5. If applying spiral tracing, begin by suspending a loop

of cable every 10 feet as shown. To determine the loop

length, divide the length of pipe length and multiply by

10.

6. Fasten

the heating cable to the pipe at 2 foot intervals

using SRK03 fiberglass tape or nylon cable ties. Do not

use vinyl electrical tape, duct tape, metal bands or wire.

7. If there is excess cable at the end of the pipe, double

remaining cable back

along the pipe.

Single Cable

Double Cable

Figure 1: Cable Placement on Pipe

SR Heating Cable Selection and

Design (continued)

Rev 11.04.12

www.king-electric.com

5