Pre-operation checklist, All safety shields must be in place, Tractor must be in proper operating condition – Alamo RHINO 95C User Manual

Page 34: Lubricate backhoe, see maintenance section, Operating directions, Engine speed, Controls, Boom/swing, Crowd/bucket, Operation

OPERATION

F-4145 01/11

Operation Section 4-2

© 2011 Alamo Group Inc.

OPERA

T

ION

CAUTION: To avoid possible injury, observe

the following safety rules BEFORE

OPERATING backhoe.

• Be sure area is clear of underground utilities or other

hazards.

• Position a barricade around work area.

• Keep bystanders a safe distance away.

PRE-OPERATION CHECKLIST

This backhoe is designed for safety, durability and operator

convenience. To insure satisfactory performance, complete

the following check list and make all necessary

adjustments before initial operation.

1.

All safety shields must be in place.

2.

Safety and operation decals must be in place,

undamaged and clean.

3.

Hydraulic hookup must be correct and all connections

tight.

4.

All bolts and pins which attach backhoe to tractor

must be in place. Check tightness of bolts and check

that all pins are retained.

5.

Tractor must be in proper operating condition.

6.

Lubricate backhoe, see MAINTENANCE SECTION.

7.

Controls must operate properly. See OPERATION

SECTION.

8.

Cycle all cylinders slowly to purge air from hydraulic

system.

9.

Hydraulic system oil level must be correct. Reservoir

level should be 1” from top of tank.

OPERATING DIRECTIONS

The terms right, left, front and back shall be from the

position of the operator when seated in the operating

position on the backhoe.

ENGINE SPEED

Speed at which backhoe operates is dependent on tractor

PTO RPM. Use a moderate engine speed to start and

increase it as your experience permits.

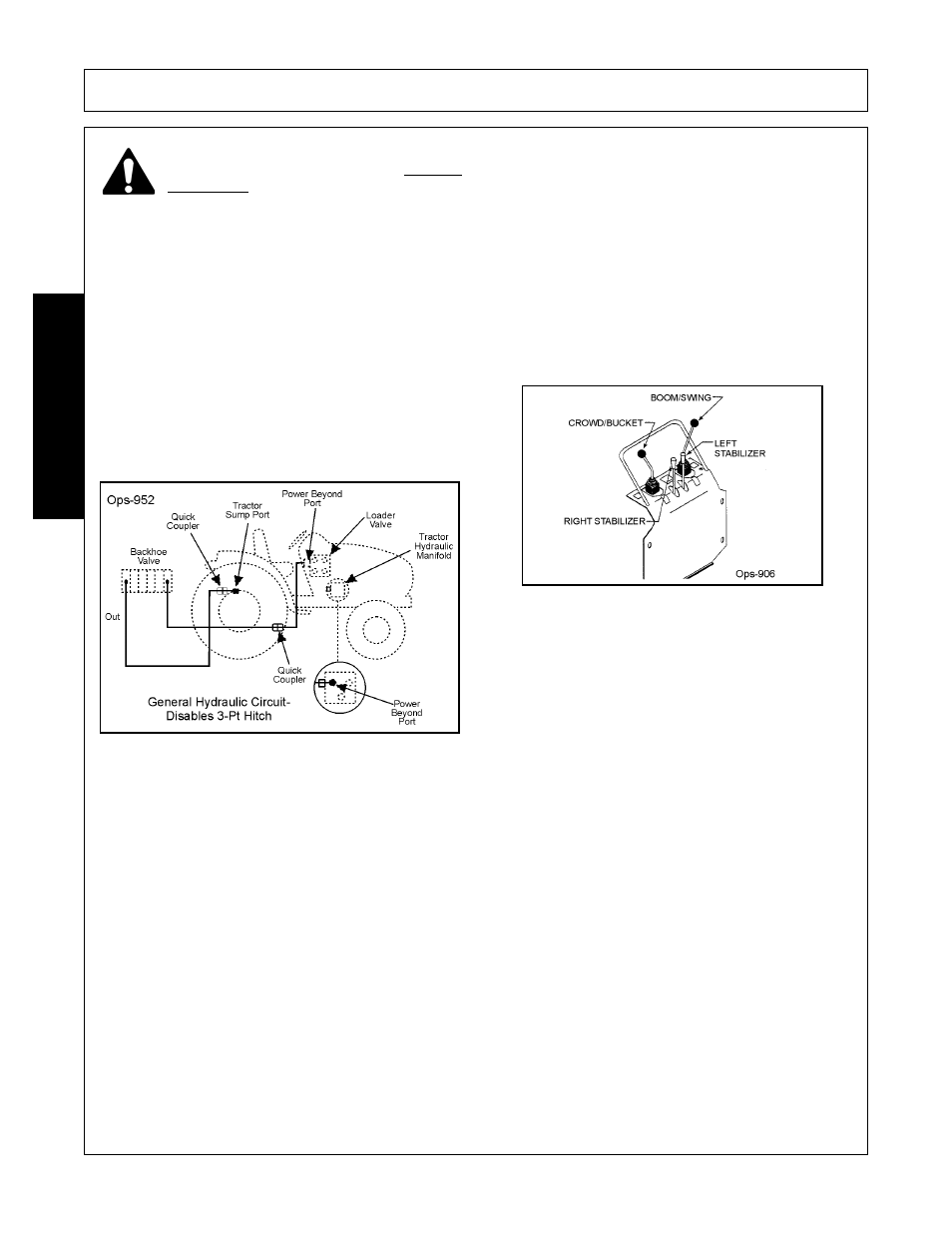

CONTROLS

The backhoe has two major control levers, Boom/Swing

and Crowd/Bucket. These controls are located on the

control panel directly ahead of the operator.

The stabilizer control levers are located between the two

major control levers.

BOOM/SWING

Push lever forward, boom moves down, away from

operator. Pull lever back, boom moves up, toward operator.

Pushing lever farther forward into detent position puts

boom into “float”. Float detent position allows boom to drift

up or down.

Move lever to left, backhoe swings left. Move lever to right,

backhoe swings right.

By moving lever to one of the intermediate positions, boom

can be swung left or right at the same time as it is being

raised or lowered, performing two operations

simultaneously.

Swing left and lower boom by moving control lever forward

and to the left.

Swing left and raise boom by moving control lever back

and to the left.

Swing right and lower boom by moving control lever

forward to the right.

Swing right and raise boom by moving control lever back

and to the right.

CROWD/BUCKET

Push lever forward, dipperstick moves away from operator.

Pull lever back, dipperstick moves toward operator.

Move lever to left, bucket curls in. Move lever right, bucket

extends out.

By moving lever to one of the intermediate positions,

dipperstick can be extended or retracted at the same time

as bucket is being loaded or dumped.

Move dipperstick away and extend bucket by moving lever

forward and to the right.

Move dipperstick away and curl bucket by moving lever

back and to the right.

Move dipperstick away and extend (dump) bucket by

moving lever forward and to the right.

Move dipperstick toward operator and extend bucket by