Harrington Hoists and Cranes MR Trolley - (MR2) User Manual

Page 23

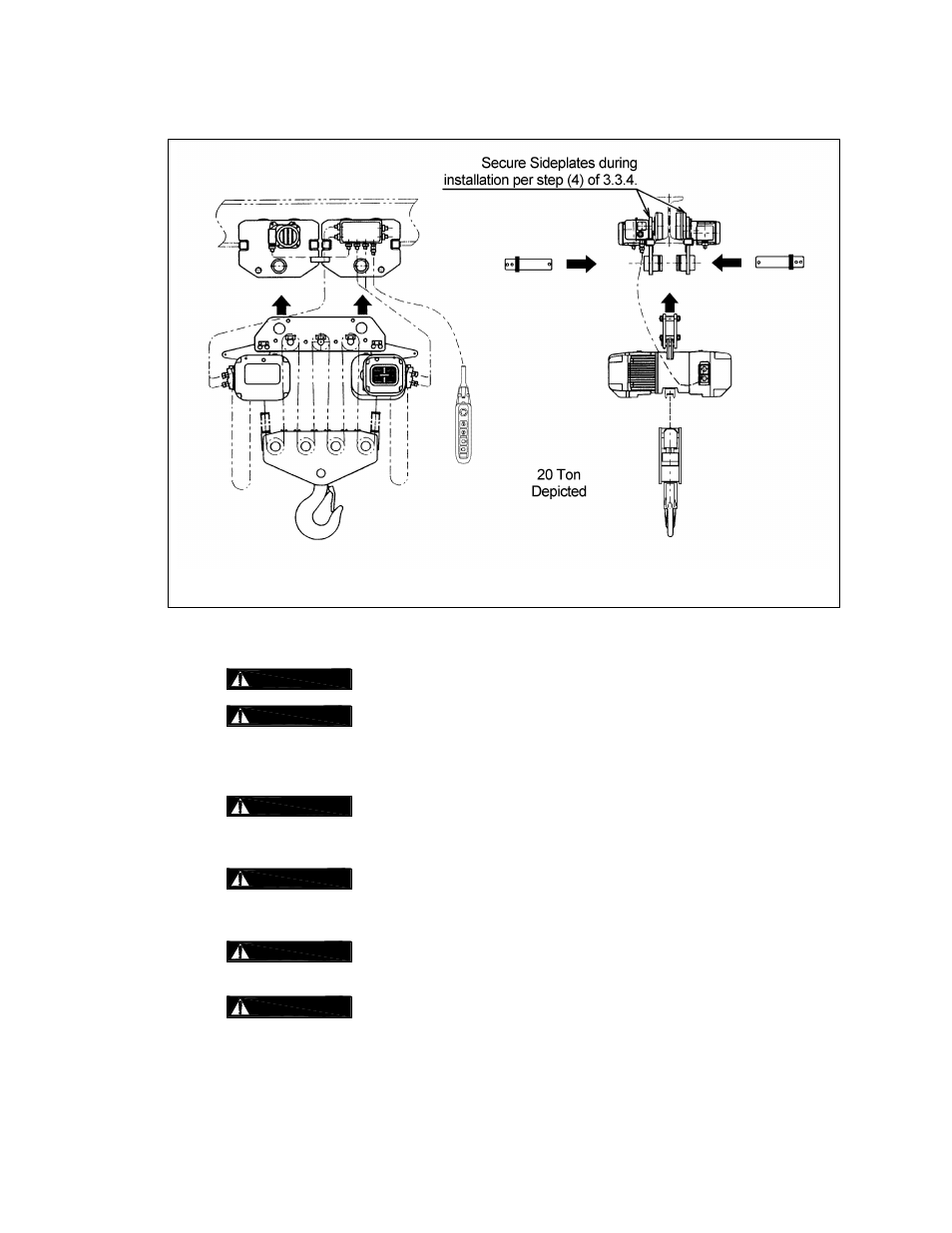

Figure 3-13 Optional trolley installation method – 8 Ton and Larger

3.4

Electrical Connections

3.4.1

Ensure that the voltage of the electric power supply is proper for the hoist or trolley.

3.4.2

Do NOT apply electronic soft-start control or voltage varying controls to the MR2

trolley. Use of such devices may cause the motor brake and other electrical components to

malfunction. Variable frequency drives MAY be used with single speed MR2 trolleys, contact

Harrington Hoists, Inc. for more information.

3.4.3

Before proceeding, ensure that the electrical supply for the hoist or trolley has

been de-energized (disconnected). Lock out and tag out in accordance with ANSI Z244.1 “Personnel

Protection -Lockout/Tagout of Energy Sources”.

3.4.4

To avoid a shock hazard, DO NOT perform ANY mechanical or electrical

maintenance on the dual speed (or VFD control) trolley or hoist within 5 minutes of de-energizing

(disconnecting) the trolley or hoist. This time allows the internal VFD capacitor to safely discharge.

3.4.5

Do Not remove power to the dual speed (or VFD control) hoist or trolley during

operation.

3.4.6

All dual speed trolleys are equiped with a VFD. The VFD is used to control the

high and low traversing speeds and accelereations. These speeds and accelerations come preset

from the factory, 80/13 feet per minute. Speed (frequency) and acceleration/deceleration time

parameters can be customized. Refer to Section 3.5.10 for trolley specific speed ranges and

instructions and Section 3.5.11 for trolley specific acceleration/deceleration ranges and instructions.

23